Pure iron based surface Fe3O4 nano-column array and preparation method thereof

A nano-column array, fe3o4 technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of difficult control of product shape and size, high decomposition temperature, environmental pollution, etc., to achieve The production efficiency is environmentally friendly, the composition is uniform, and the process parameters are precise and controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

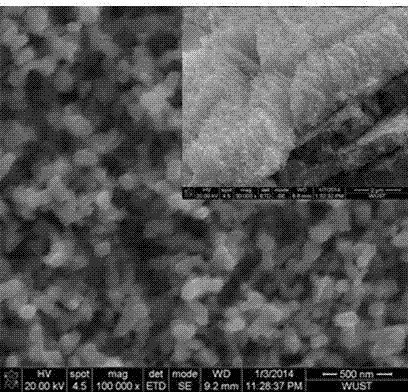

Image

Examples

Embodiment 1

[0021] A pure iron-based surface Fe 3 o 4 Nanopillar arrays and methods of making them. The pure iron after surface pretreatment is anodized in the ammonium fluoride-water-ethylene glycol system electrolyte; take it out, clean it, and blow it dry. Then, in a hydrogen atmosphere, the temperature was raised from room temperature to 400-600 °C at a rate of 5-8 °C / min, kept for 3-5 hours, and naturally cooled with the furnace to obtain pure iron-based surface Fe. 3 o 4 array of nanopillars.

[0022] The technical parameters of the anodizing treatment are: the voltage of the anodizing treatment is 20-30V, the temperature of the anodizing treatment is 45-60°C, and the time of the anodizing treatment is 0.05-0.5h.

[0023] The mass fraction of ammonium fluoride in the ammonium fluoride-water-ethylene glycol system electrolyte is 0.2-0.35%, and the volume fraction of water is 1.5-2%.

[0024] The pure iron-based surface Fe obtained in this embodiment 3 o 4 The layer thickness o...

Embodiment 2

[0026] A pure iron-based surface Fe 3 o 4 Nanopillar arrays and methods of making them. The pure iron after surface pretreatment is anodized in the ammonium fluoride-water-ethylene glycol system electrolyte; take it out, clean it, and blow it dry. Then, in a hydrogen atmosphere, the temperature was raised from room temperature to 550-700 °C at a rate of 8-12 °C / min, kept for 4-7 hours, and naturally cooled with the furnace to obtain pure iron-based surface Fe. 3 o 4 array of nanopillars.

[0027] The technical parameters of the anodizing treatment are: the voltage of the anodizing treatment is 30-45V, the temperature of the anodizing treatment is 35-50°C, and the time of the anodizing treatment is 0.1-0.8h.

[0028] The mass fraction of ammonium fluoride in the ammonium fluoride-water-ethylene glycol system electrolyte is 0.3-0.45%, and the volume fraction of water is 2.0-2.5%.

[0029] The pure iron-based surface Fe obtained in this embodiment 3 o 4 The layer thickness...

Embodiment 3

[0031] A pure iron-based surface Fe 3 o 4 Nanopillar arrays and methods of making them. The pure iron after surface pretreatment is anodized in the ammonium fluoride-water-ethylene glycol system electrolyte; take it out, clean it, and blow it dry. Then, in a hydrogen atmosphere, the temperature was raised from room temperature to 600-800°C at a heating rate of 12-15°C / min, kept for 6-8 hours, and cooled naturally with the furnace to obtain pure iron-based surface Fe. 3 o 4 array of nanopillars.

[0032]The technical parameters of the anodizing treatment are: the voltage of the anodizing treatment is 45-60V, the temperature of the anodizing treatment is 20-40°C, and the time of the anodizing treatment is 0.5-1.0h.

[0033] The mass fraction of ammonium fluoride in the ammonium fluoride-water-ethylene glycol system electrolyte is 0.4-0.5%, and the volume fraction of water is 2.5-3.0%.

[0034] The pure iron-based surface Fe obtained in this embodiment 3 o 4 The layer thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com