Method for coloration hot dip galvanization of hollow steel

A hot-dip galvanizing and coloring technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

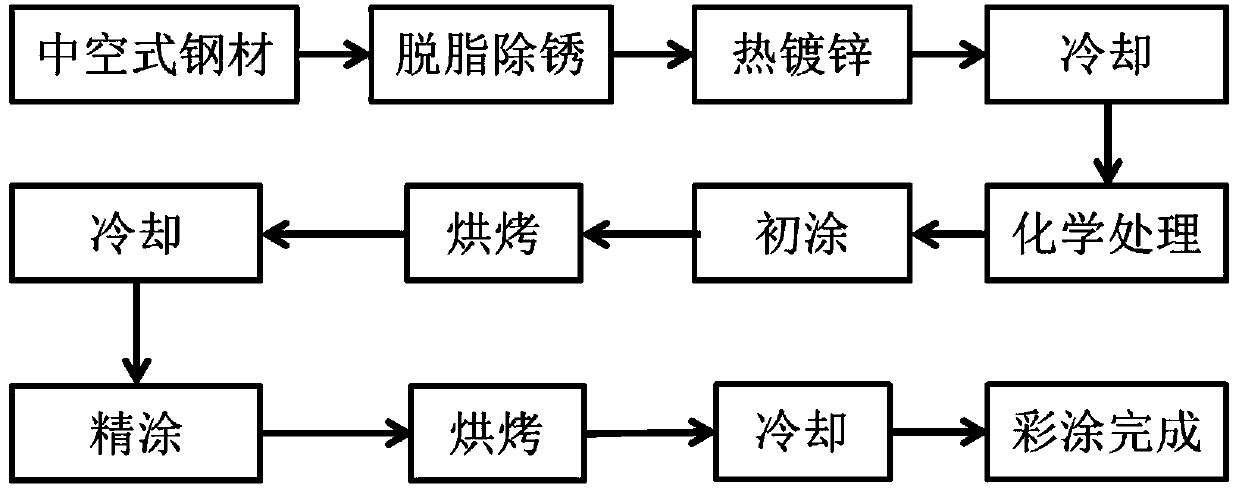

[0104] For the method of color hot-dip galvanizing of round pipe steel with a wall thickness of 0.5mm, the process flow diagram is shown in Figure 4 . Among them, the size of the round pipe steel is DN20×0.5×100mm. Firstly, Zn-Mn master alloy, Zn-Y master alloy and Zn-Ce master alloy are prepared, and then the prepared master alloy is used to prepare special color hot-dip galvanized Liquid, pre-treat the surface of the plated parts, and finally carry out hot-dip galvanizing operation, the specific operation steps are as follows:

[0105] Step 1, prepare Zn-Mn master alloy, Zn-Y master alloy, Zn-Ce master alloy

[0106] (1) First place the zinc ingot in the smelting equipment and heat it to 540°C with the furnace. After the zinc ingot is completely melted, a zinc liquid is obtained; add Mn to the zinc liquid and control the temperature at 540°C. When the Mn is completely melted in In the zinc liquid, fully stir, keep warm for 10min, cast in the mold, obtain Zn-Mn (5.2wt.%Mn)...

Embodiment 2

[0126] A method for color hot-dip galvanizing of round pipe steel with a wall thickness of 5mm, wherein the size of the round pipe steel is DN50×5×100mm, firstly, Zn-Mn master alloy, Zn-Y master alloy, Zn-Ce master alloy are prepared , and then use the prepared master alloy to prepare a special colored hot-dip galvanizing bath, pretreat the surface of the plated parts, and finally perform a hot-dip galvanizing operation. The specific operation steps are as follows:

[0127] Step 1, prepare Zn-Mn master alloy, Zn-Y master alloy, Zn-Ce master alloy

[0128] (1) First place the zinc ingot in the smelting equipment and heat it to 550°C with the furnace. After the zinc ingot is completely melted, a zinc liquid is obtained; add Mn to the zinc liquid and control the temperature at 550°C. When the Mn is completely melted in In the zinc liquid, fully stir, keep warm for 15min, cast in the mold, obtain Zn-Mn (5.1wt.%Mn) intermediate alloy;

[0129] (2) First place the zinc ingot in the...

Embodiment 3

[0148] A method for performing color hot-dip galvanizing on a square tube steel with a wall thickness of 10mm, wherein the size specification of the square tube steel is 80×60×10×100mm. First, prepare Zn-Mn master alloy, Zn-Y master alloy, Zn-Ce master alloy, and then use the prepared master alloy to prepare special colored hot-dip galvanizing bath, pretreat the surface of the plated parts, and finally carry out Hot-dip plating operation, the specific operation steps are as follows:

[0149] Step 1, prepare Zn-Mn master alloy, Zn-Y master alloy, Zn-Ce master alloy

[0150] (1) First place the zinc ingot in the smelting equipment and heat it to 555°C with the furnace. After the zinc ingot is completely melted, a zinc liquid is obtained; add Mn to the zinc liquid and control the temperature at 555°C. When the Mn is completely melted in In the zinc liquid, fully stir, keep warm for 20min, cast in the mould, obtain Zn-Mn (4.9wt.%Mn) intermediate alloy;

[0151] (2) First place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com