Heating circulating system of jig dyeing machine

A heating system and circulation system technology, applied in the field of printing and dyeing machinery, can solve the problems of inability to recycle water vapor, different pressures, uneven dyeing of fabrics, etc., to solve the problem of dyeing temperature, no temperature dead angle, improve dyeing quality The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

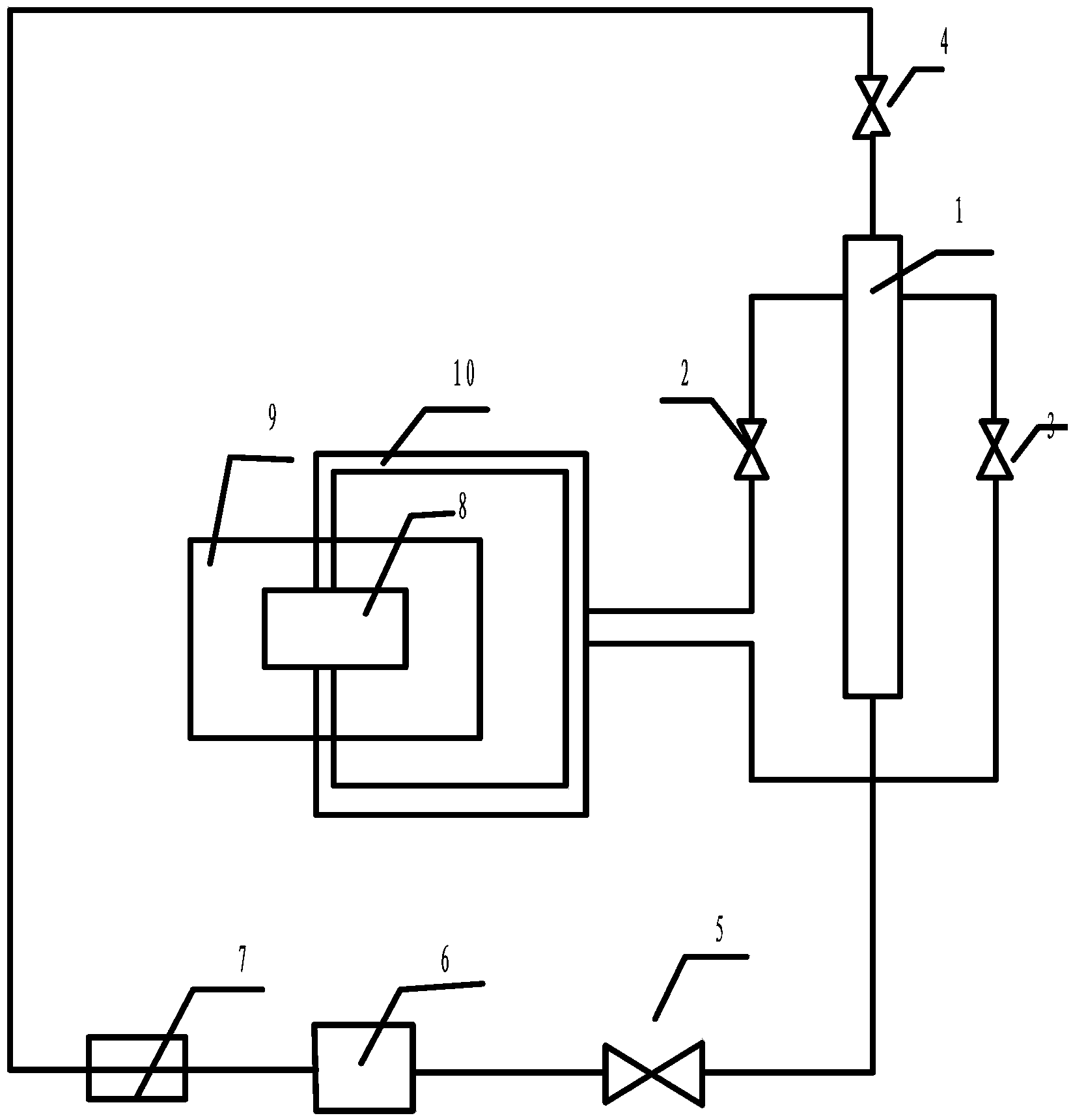

[0015] Such as figure 1 As shown, the system consists of vertical sub-steam drum (1), automatic ventilation valve (2), manual control valve (3), main valve (4), drain valve (5), circulating water recovery tank (6), A hydraulic pump (7), a heating pipe (8), a dye tank (9), and a steam inlet pipe (10) are connected to each other.

[0016] The main valve (4) is opened, the water and its steam pass through the vertical steam distribution drum (1) to separate the gas and water, the water vapor enters the steam inlet pipe (10) through the automatic ventilation valve (2), and the water passes through the steam trap (5 ) into the circulating water recovery tank (6), the water vapor enters the heating tube (8) through the steam inlet pipe (10), and the water in the circulating water recovery tank (6) is compressed by the hydraulic pump (7) through the main valve (4) Enter the vertical sub-steam drum (1), so that the water and its steam can be recycled.

[0017] The applicant declares...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com