Nut implantation machine and implantation method thereof

An implanting machine and nut technology, which is applied in the field of hot-melting plastic parts implanted into metal parts, can solve the problems of low efficiency, low labor consumption, unstable process parameters, etc., and achieve the effect of accurate temperature and increased production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

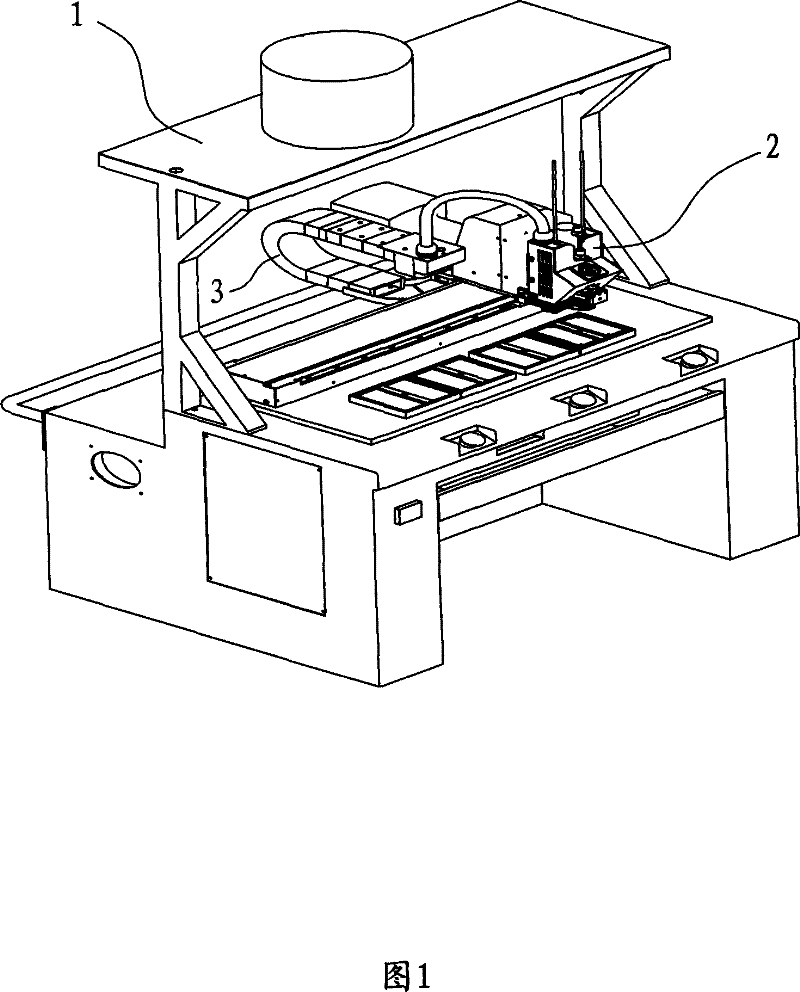

[0038] see Figures 1 to 3 As shown, the present invention discloses a nut implantation machine, which includes: implantation cabinet body 1, machine head 2, wherein:

[0039] A three-axis coordinate manipulator 3 is arranged on the cabinet body 1, and the machine head 2 is arranged on its Z axis.

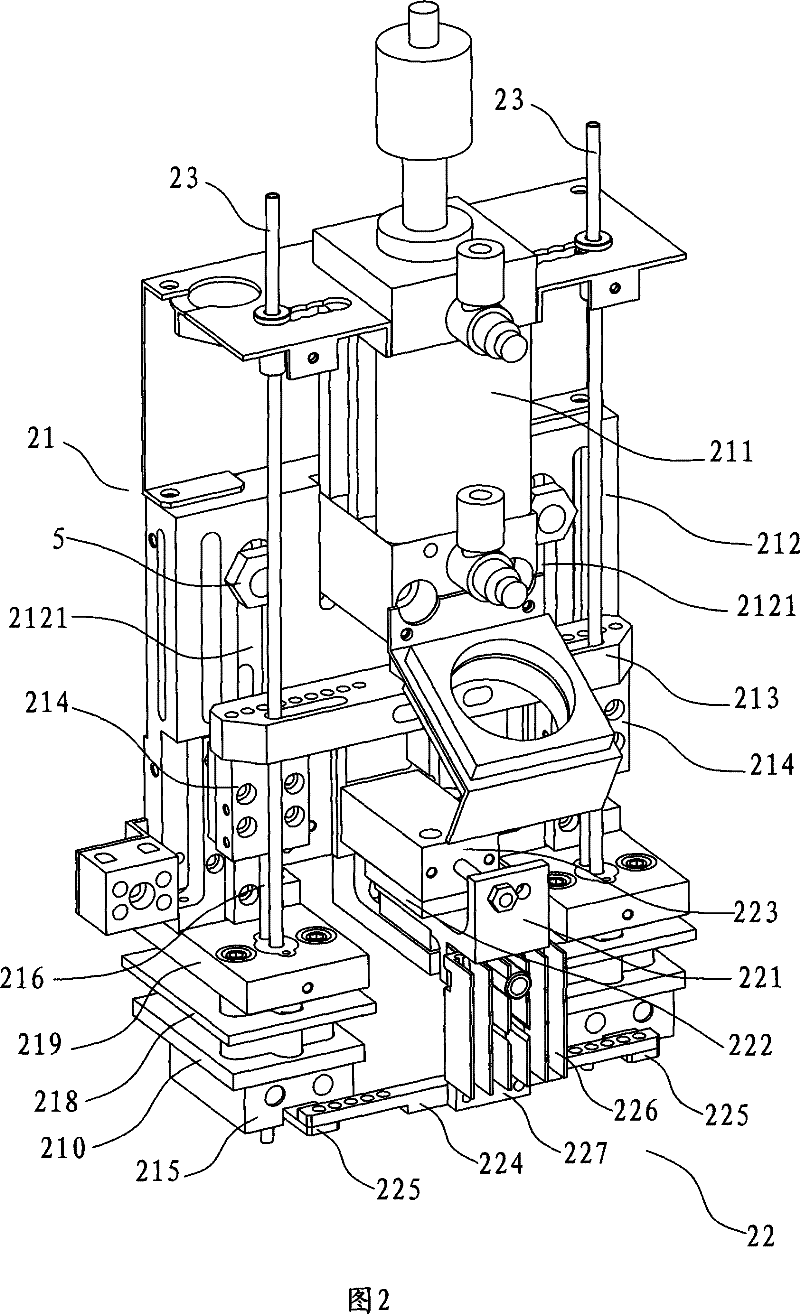

[0040] The machine head 2 is provided with an implanting device 21, a feeding device 22 and a feeding tube 23 which can withstand high temperature. 22 can push the nut into the implant device 21 .

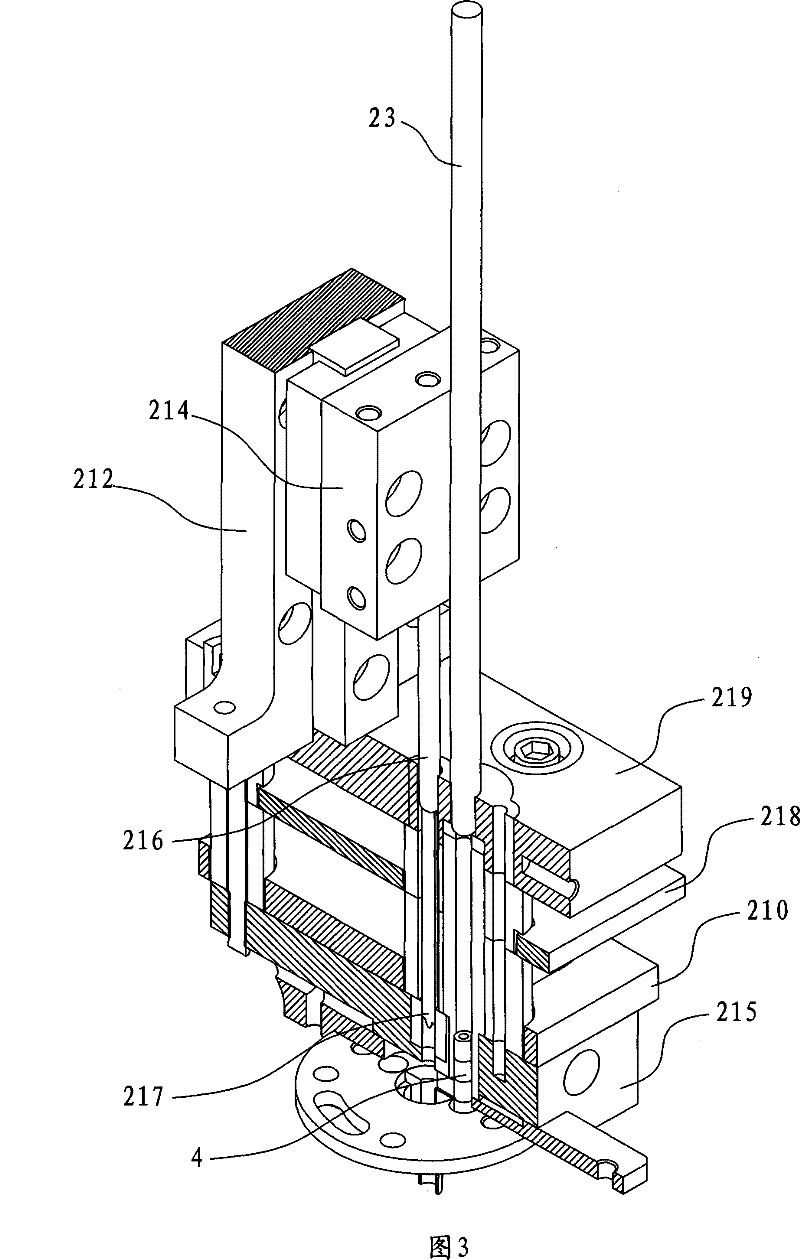

[0041] Such as figure 2 As shown, the implanting device 21 includes an implanting cylinder 211, a feeding implant slide rail plate 212, an implanting cylinder pressing plate 213, a punch slide 214, a heating seat 215, a punch 216, and a punch 217. The feeding cylinder 211 is set on the feeding implant slide rail plate 212, and the implanting cylinder pressing plate 213 is fixed below it, the punching needle slide 214 is set under the implanting cylinder pressing plate 213, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com