A material clamping flip nut implantation machine and its implantation method

A technology of turning nuts and implanting machines, which is applied in the field of inserting turning nuts implanting machines and their implantation, which can solve problems such as the difficulty of implanting flat nuts, achieve intuitive and convenient machine adjustment and repair, save costs, space, and personnel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the new solution, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

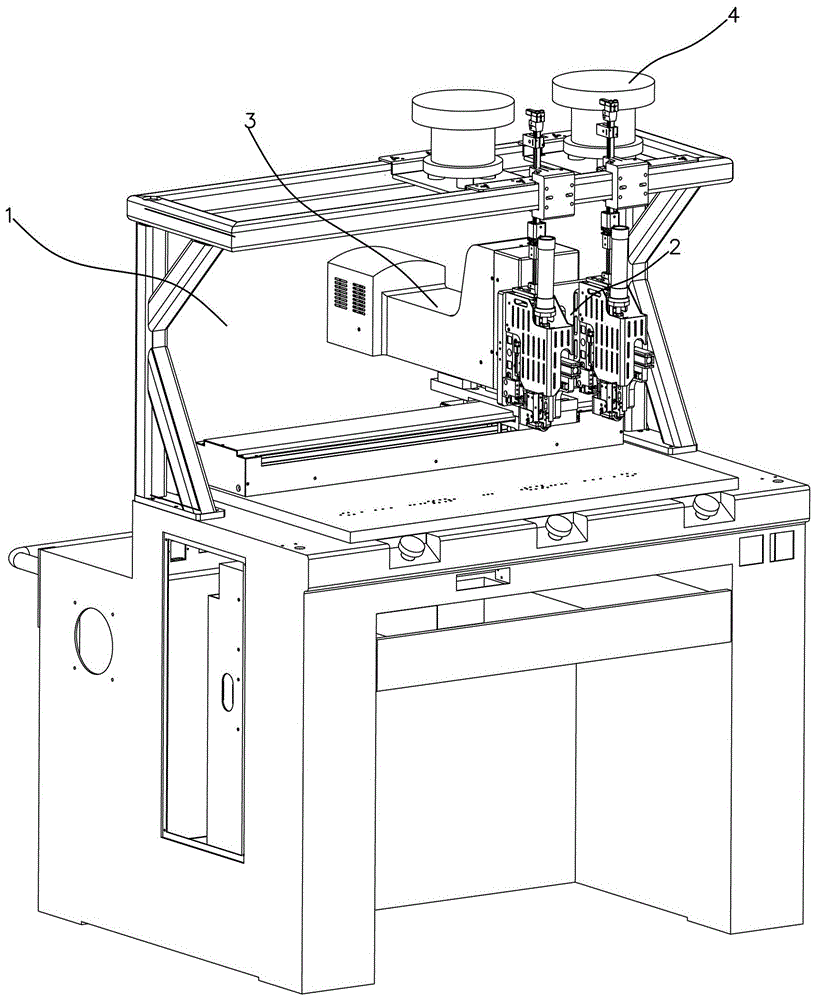

[0041] Such as Figure 1-2 As shown, a clamping and flipping nut implantation machine includes a cabinet body 1 and a machine head 2. The cabinet body 1 is provided with a three-axis coordinate manipulator 3, and the machine head 2 is arranged on its Z-axis.

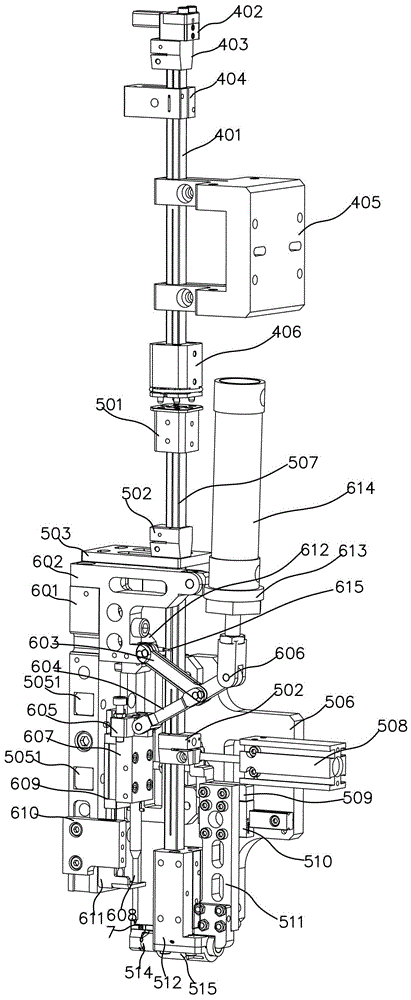

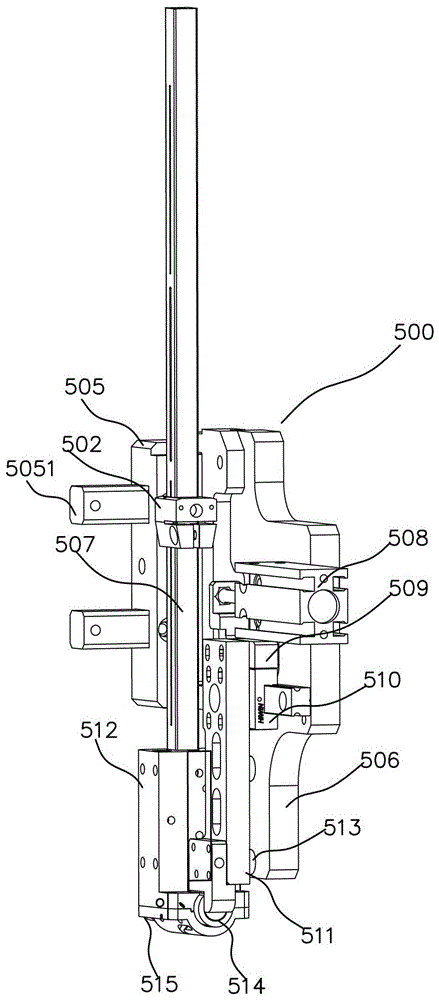

[0042] It also includes: two sets of feeding devices 400 fixed on the cabinet body 1 , two sets of receiving devices 500 on the machine head 2 , and two sets of implanting devices 600 on the machine head 2 . The material receiving device is located below the feeding device and is connected with the feeding device; the implanting device is connected with the material receiving device.

[0043] The feeding device 400 includes: a feeding feeding column 401, a feeding vibrating plate receiving part 402, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com