Thin nut implanting machine and nut implanting method thereof

An implanter and nut technology, which is applied in the field of implanter for implanting thin nuts, can solve problems such as difficulty in implanting flat nuts, achieve intuitive and convenient machine adjustment and repair, increase production capacity, and facilitate machine replacement and machine adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the new solution, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

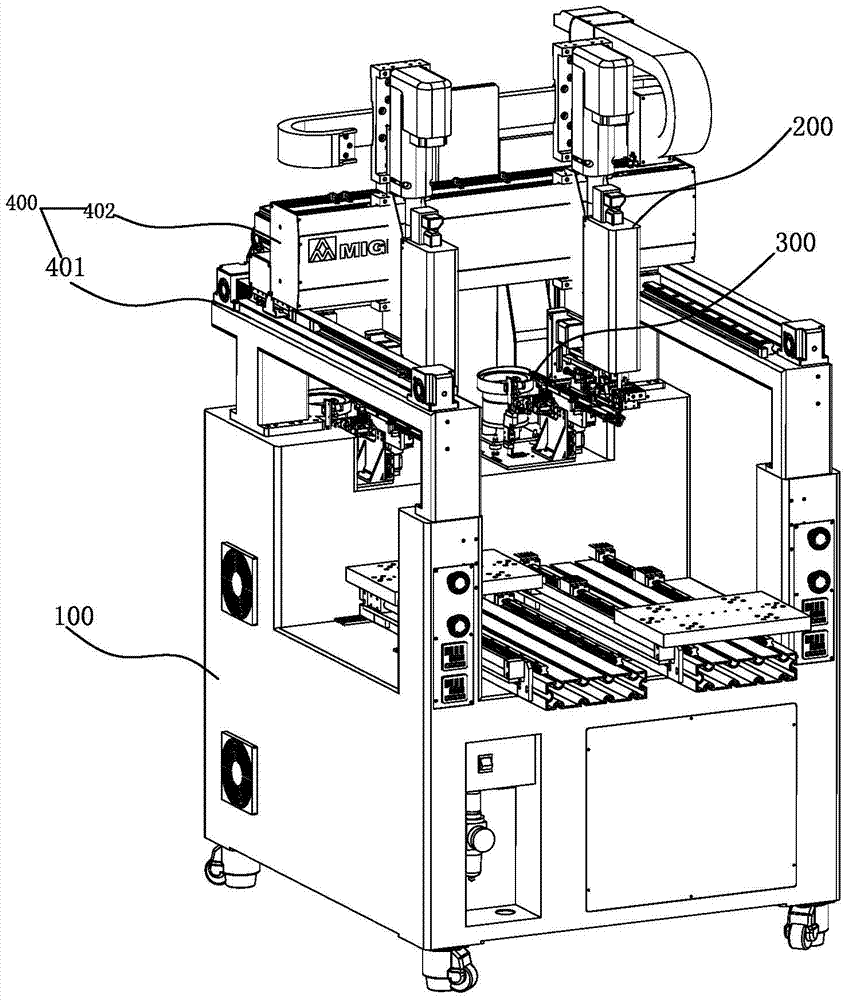

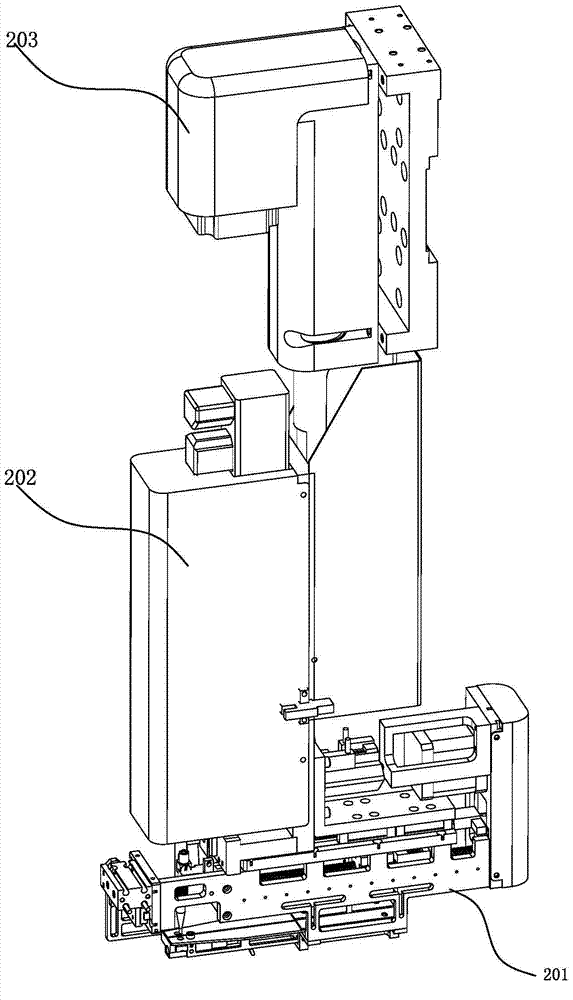

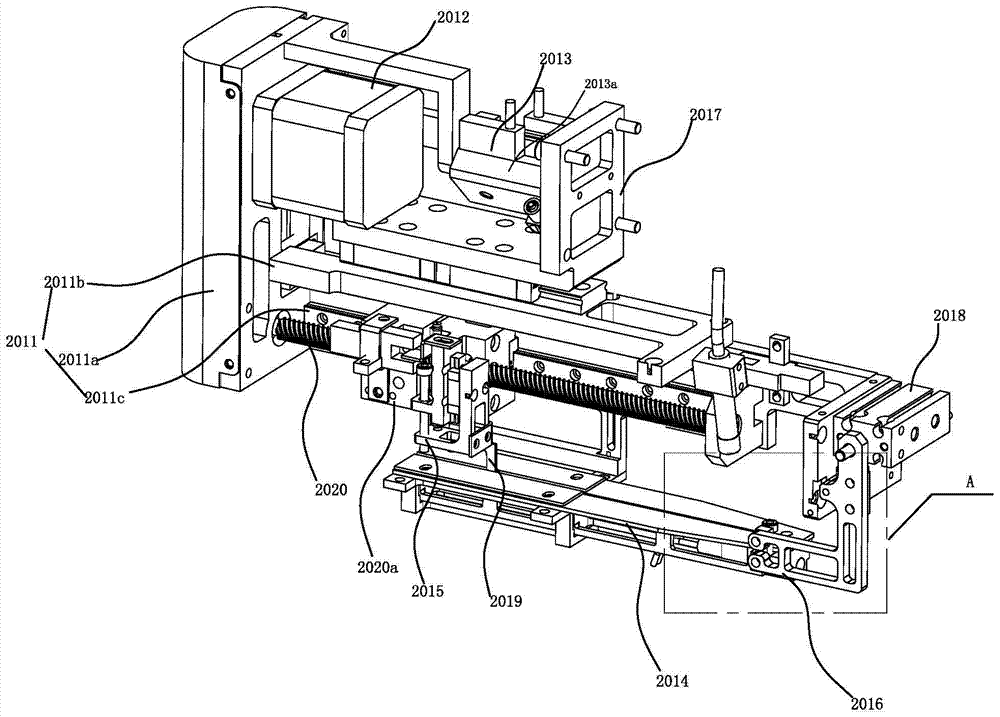

[0047] like figure 1 As shown, a thin nut implanting machine includes a cabinet body 100, a machine head 200, a set of feeding device 300 fixed on the cabinet body, and a two-coordinate robot assembly 400 is also arranged on the cabinet body; wherein:

[0048] The dual-coordinate robot assembly consists of a set of independent dual X-axes 401 and a set of gantry-type Y-axes 402 for connecting the dual X-axes.

[0049] like Figure 7-8 As shown, the feeding device includes: feeding feeding box fixing seat 301, feeding feeding box 302, photoelectric detection device 303, screening material assembly 304, CCD detection device 305, pushing material assembly 306, vibrating plate 307; photoelectric detection The device is located at the end of the material feeding bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com