LED (Light Emitting Diode) UV (ultraviolet) lamp

A lamp body and lamp bead technology, applied in the field of lighting, can solve the problems of high maintenance cost, expensive consumables, high price, etc., and achieve the effect of reducing two-way drag belts, simplifying the printing process, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

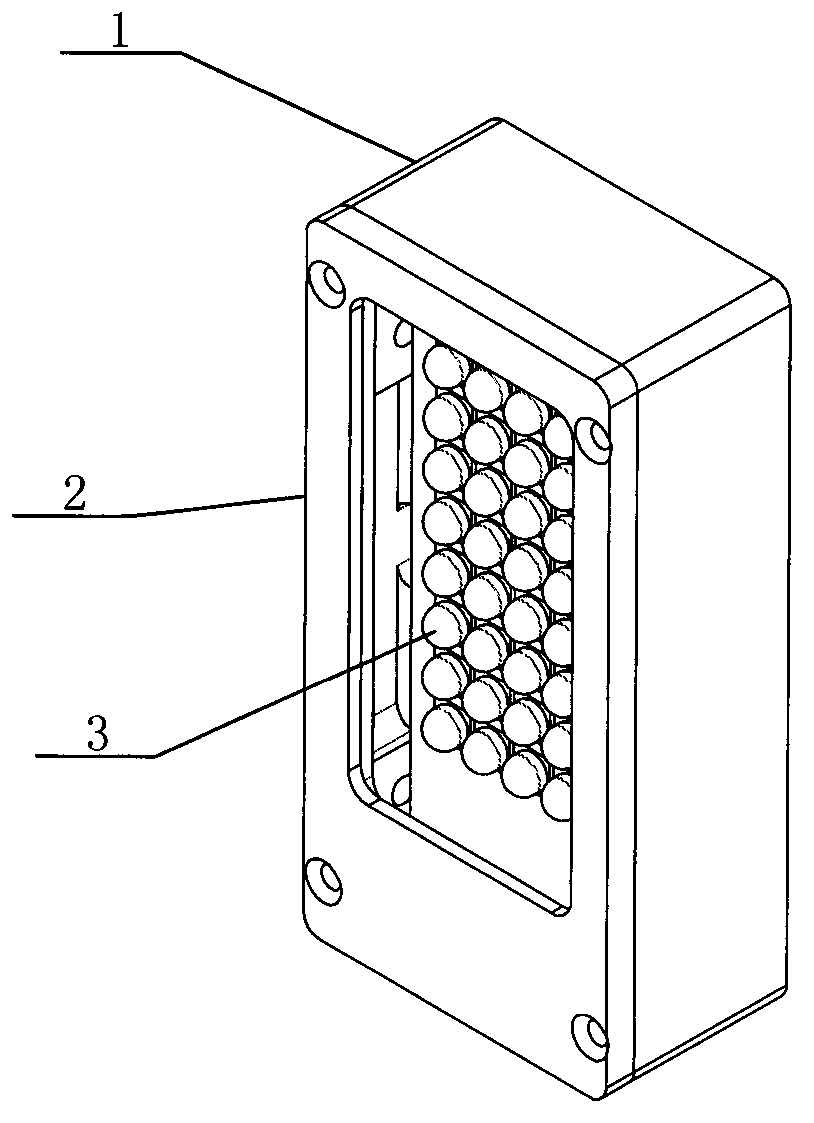

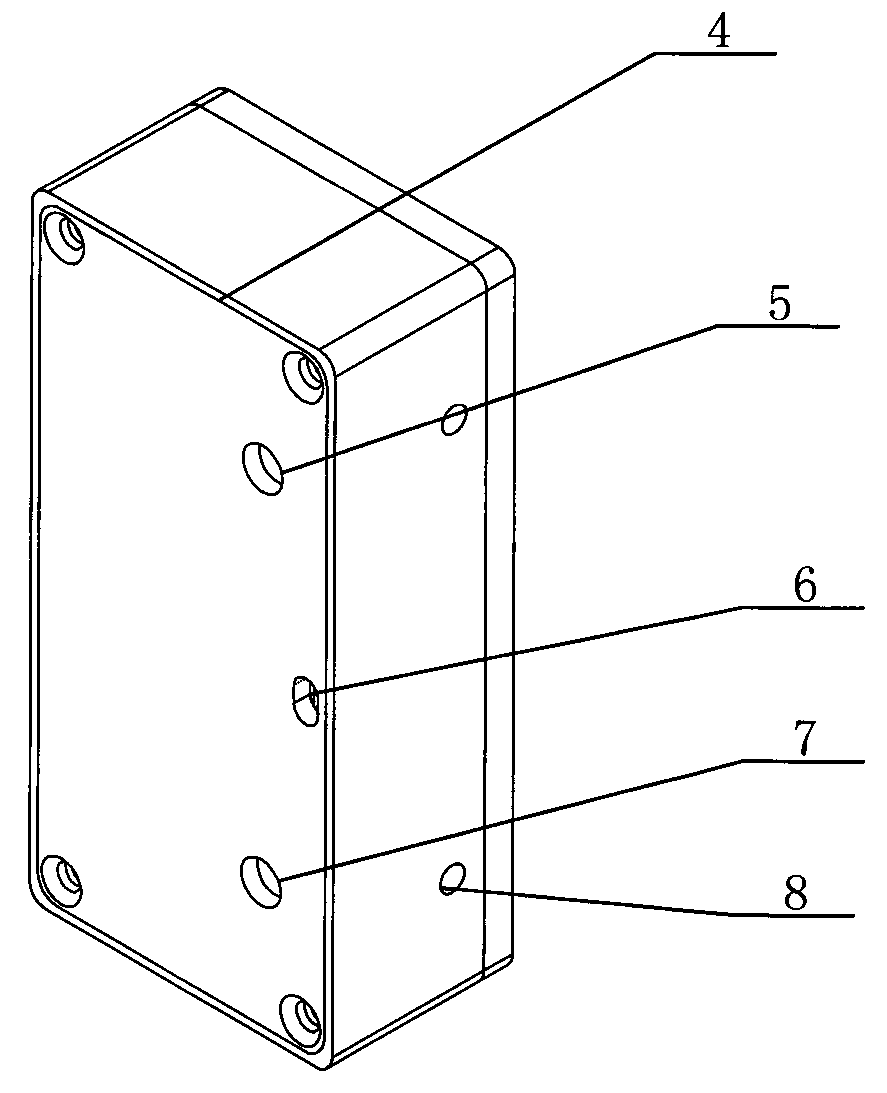

[0015] see Figure 1-2 , this specific embodiment adopts the following technical solutions: it includes a lamp body 1, a lamp cap 2, a lamp bead 3, an upper sealing plate 4, a water inlet 5, a wire passing hole 6, a water inlet 7 and an installation screw hole 8; The lower part of the lamp body 1 is provided with a lamp cap 2, the interior of the lamp body 1 is provided with a lamp bead 3, the upper part of the lamp body 1 is provided with an upper sealing plate 4, and the upper sealing plate 4 is provided with a water inlet 5, and the water inlet 5 The lower part of the lamp body is provided with a wire hole 6, the lower part of the wire hole 6 is provided with a water inlet hole 7, and the side of the lamp body 1 is provided with a mounting screw hole 8.

[0016] This specific embodiment has the characteristics of constant light intensity, excellent temperature control, portability and environmental protection, and almost zero maintenance cost, which plays a role in promotin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com