Method for synthetizing white light polymer

A synthesis method and polymer technology, applied in chemical instruments and methods, luminescent materials, gas discharge lamps, etc., can solve the problems of low energy utilization efficiency, loss of luminescent function of materials, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

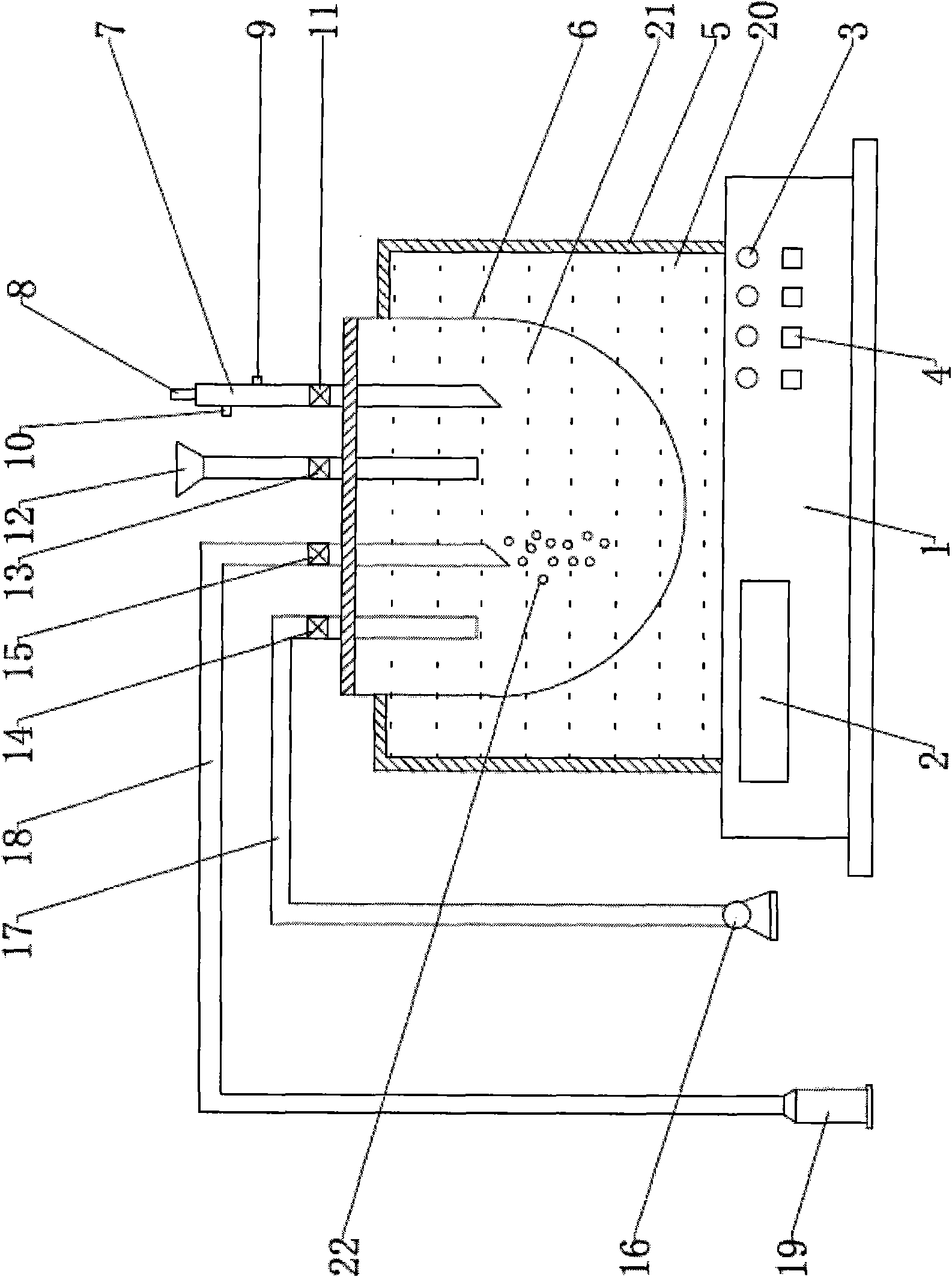

[0164] The present invention will be further described below in conjunction with accompanying drawing:

[0165] figure 1 As shown, it is the state diagram of the synthesis state of the final product of white light polymer, and the positions of each part must be correct, according to the proportion, and operate in sequence.

[0166] The chemical substances used in the preparation are determined according to the pre-set range in grams, milliliters, millimeters, centimeters 3 is the unit of measurement.

[0167] The three-necked flasks, four-necked flasks, beakers, containers, quartz boats, stirring rods, water circulation condensers, recrystallization funnels, dropping funnels, column chromatography tubes, suction filtration bottles, etc. used in the preparation must be strictly cleaned with deionized water. It is clean to prevent the intervention of other impurities, so as not to produce by-products.

[0168] Synthesis is a complex chemical reaction process, using a variety ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com