Organic electroluminescence device and manufacturing method thereof

An electroluminescent device, organic technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of large light loss and low light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

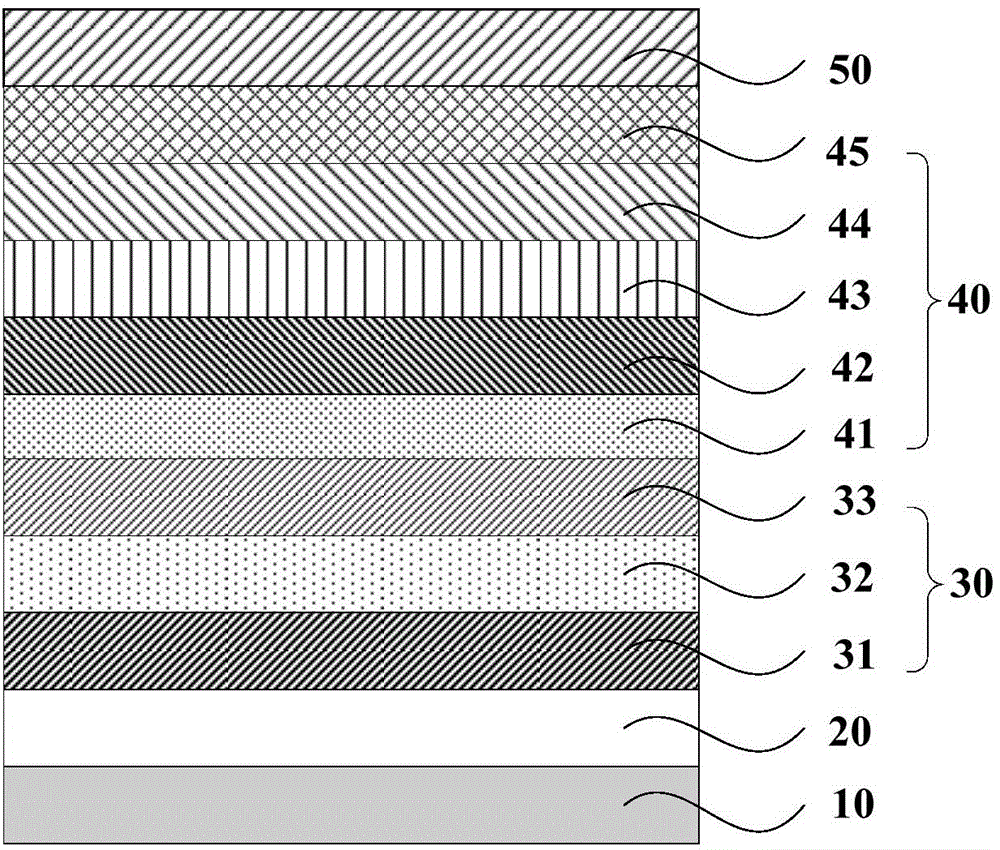

[0047] figure 1 A schematic structural diagram of an organic electroluminescent device provided in this embodiment. like figure 1 As shown, the organic electroluminescent device is sequentially stacked with a substrate 10 , an anode 20 , a scattering layer 30 , an organic light-emitting functional layer 40 and a cathode 50 from bottom to top. Wherein, the scattering layer 30 includes a first doped layer 31, an iron salt layer 32, and a second doped layer 33 that are stacked sequentially from bottom to top; The hole injection layer 41 , the hole transport layer 42 , the light emitting layer 43 , the electron transport layer 44 and the electron injection layer 45 . More specifically, the grade of the substrate 10 is N-LASF44, the anode 20 is a 150nm thick ITO layer, and the first doped layer 31 is a 30nm thick F4-TCNQ:FeCl 3 layer, the iron salt layer 32 is 15nm thick FeCl 3 layer, the second doped layer 33 is 150nm thick 1T-NATA:TiO 2 layer, the hole injection layer 41 is ...

Embodiment 2

[0056] Embodiment 2: the preparation of a kind of organic electroluminescence device; Device structure is: glass substrate / IZO / 1T-NATA:FeBr 3 / Fe 2 S 3 / F4-TCNQ:TiO 2 / MoO 3 / NPB / ADN / TPBi / CsN 3 / Al.

[0057] Its preparation method is as follows:

[0058] (1) Use N-LAF36 optical glass as the substrate, rinse the glass substrate with distilled water and ethanol, and soak it in isopropanol for 12 hours.

[0059](2) Prepare an 80nm thick IZO anode film on the cleaned glass substrate by magnetron sputtering; control the acceleration voltage of magnetron sputtering to 300V, the magnetic induction intensity is about 50G, and the power density is 40W / cm 2 , the background vacuum is 2×10 -3 Pa.

[0060] (3) Prepare a scattering layer on the IZO anode film, including a first doped layer, an iron salt layer and a second doped layer that are sequentially stacked. First prepare the first doped layer, which is 1T-NATA:FeBr 3 , 1T-NATA with FeBr 3 The mass ratio is 40:1, using the...

Embodiment 3

[0064] Embodiment 3: the preparation of a kind of organic electroluminescence device; Device structure is: glass substrate / AZO / 2T-NATA:Fe 2 S 3 / FeBr 3 / 2T-NATA:TiO 2 / V 2 o 5 / TCTA / Alq3 / Bphen / LiF / Au. Its preparation method is as follows:

[0065] (1) The optical glass with brand name N-LASF31A is used as the substrate. After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol for 24 hours.

[0066] (2) Prepare a 300nm-thick AZO anode film on the cleaned glass substrate by magnetron sputtering; control the acceleration voltage of magnetron sputtering: 800V, magnetic induction: 200G, power density: 1W / cm 2 ,, the background vacuum is 5×10 -5 Pa.

[0067] (3) Prepare a scattering layer on the AZO anode film, including a first doped layer, an iron salt layer and a second doped layer that are sequentially stacked. Prepare the first doped layer first, the material is 2T-NATA:Fe 2 S 3 , 2T-NATA and Fe 2 S 3 The mass ratio is 10:1, therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com