Hot-press laminating mechanism for overlapping front edge of sun shield of automobile

A car sun visor and hemming technology, which is applied in the direction of lamination, laminating device, layered products, etc., can solve the problems of long production cycle time, inconvenient operation by personnel, and high product manufacturing cost, so as to improve the bonding of hemming The effect of improving quality, reducing labor intensity of workers, and saving lamination cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

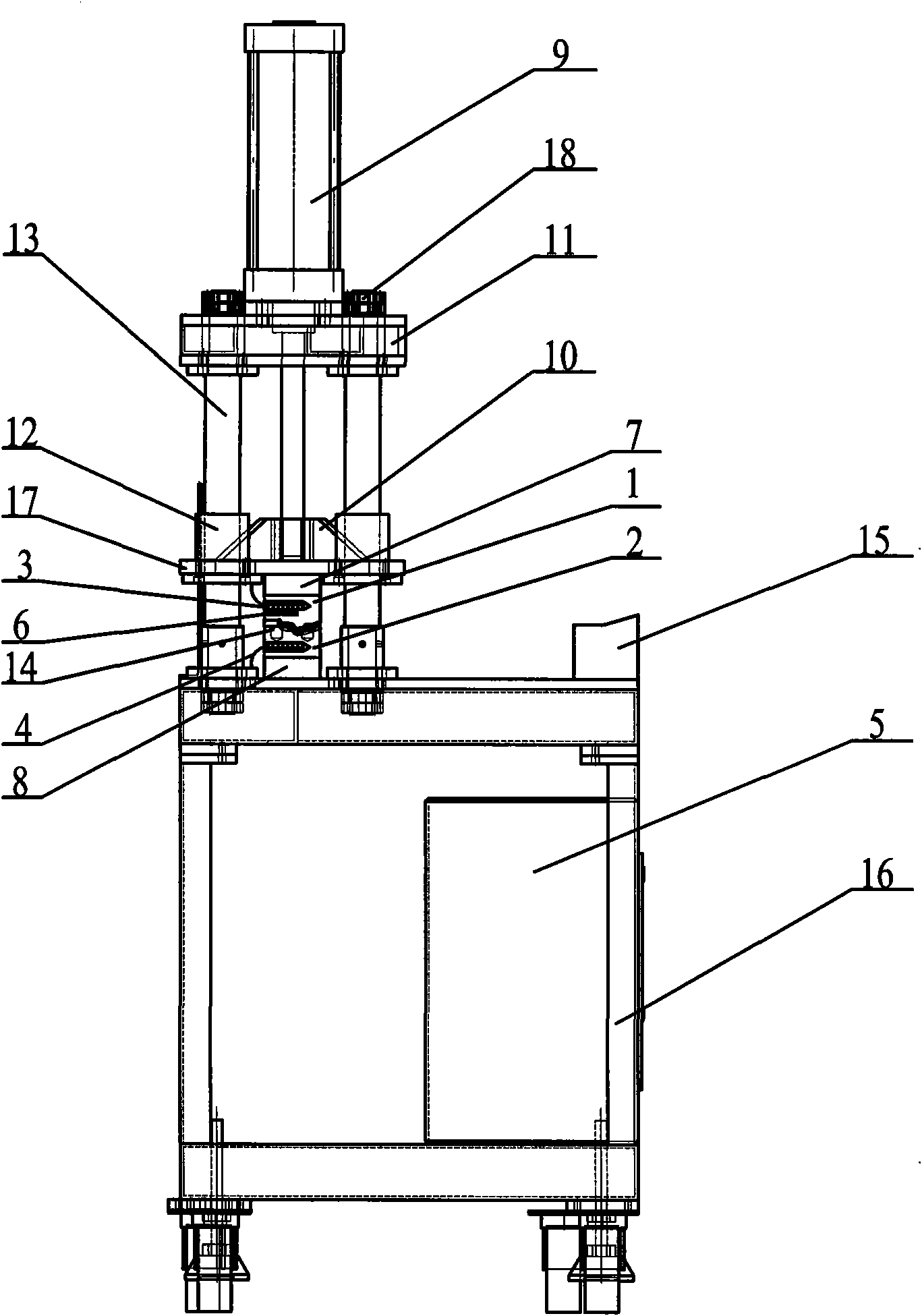

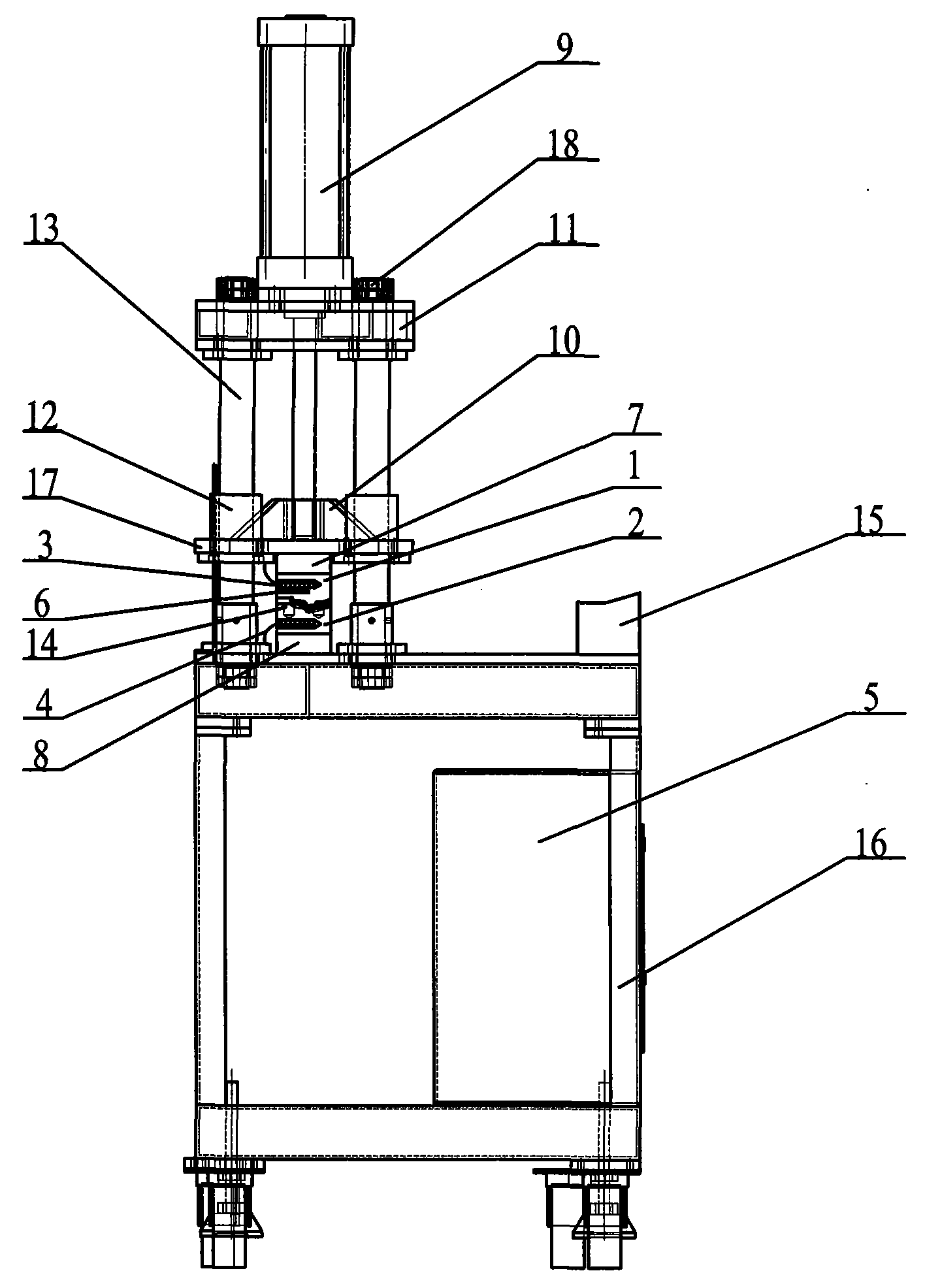

[0010] Such as figure 1 Shown: the present invention includes upper molding surface heating mold 1, lower molding surface heating mold 2, heating tube 3, heating pipe wire 4, temperature control cabinet 5, temperature sensor 6, upper heat insulation board 7, lower heat insulation board 8, Lifting cylinder 9, connecting block 10, fixed plate 11, lifting guide sleeve 12, lifting guide column 13, mold four-corner guide column guide sleeve 14, auxiliary support mold 15, base 16, connecting plate 17 and fastening nut 18.

[0011] Such as figure 1 As shown: the base 16 is provided with a lifting guide post 13, there are two lifting guide posts 13, and the lifting guide post 13 is fixed on the base 16. The other end of the lifting guide column 13 corresponding to the base 16 is provided with a fixed plate 11, and the fixed plate 11 and the lifting guide column 13 are tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com