Glass-to-glass bonding device produced on basis of capacitive touch screen.

A capacitive touch screen and bonding device technology, which is applied in lamination devices, electronic equipment, layered products, etc., can solve the problem of small application range of fixtures, achieve stable and reliable limit effect, wide application range, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

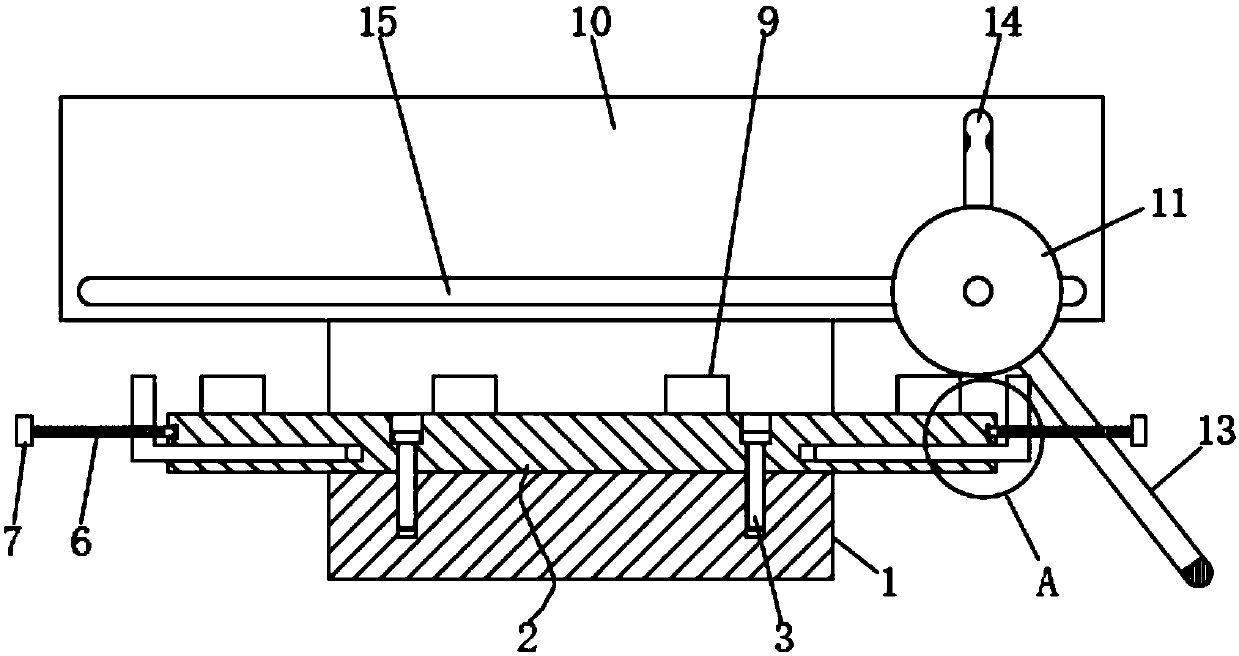

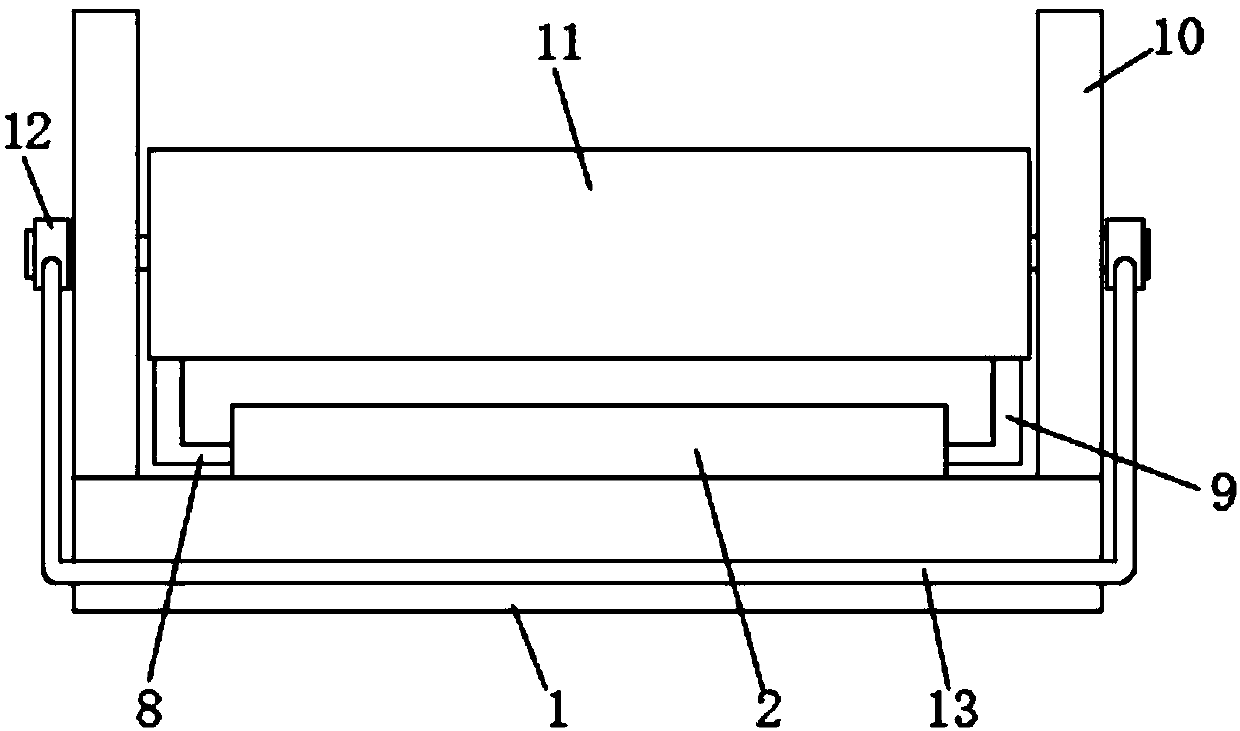

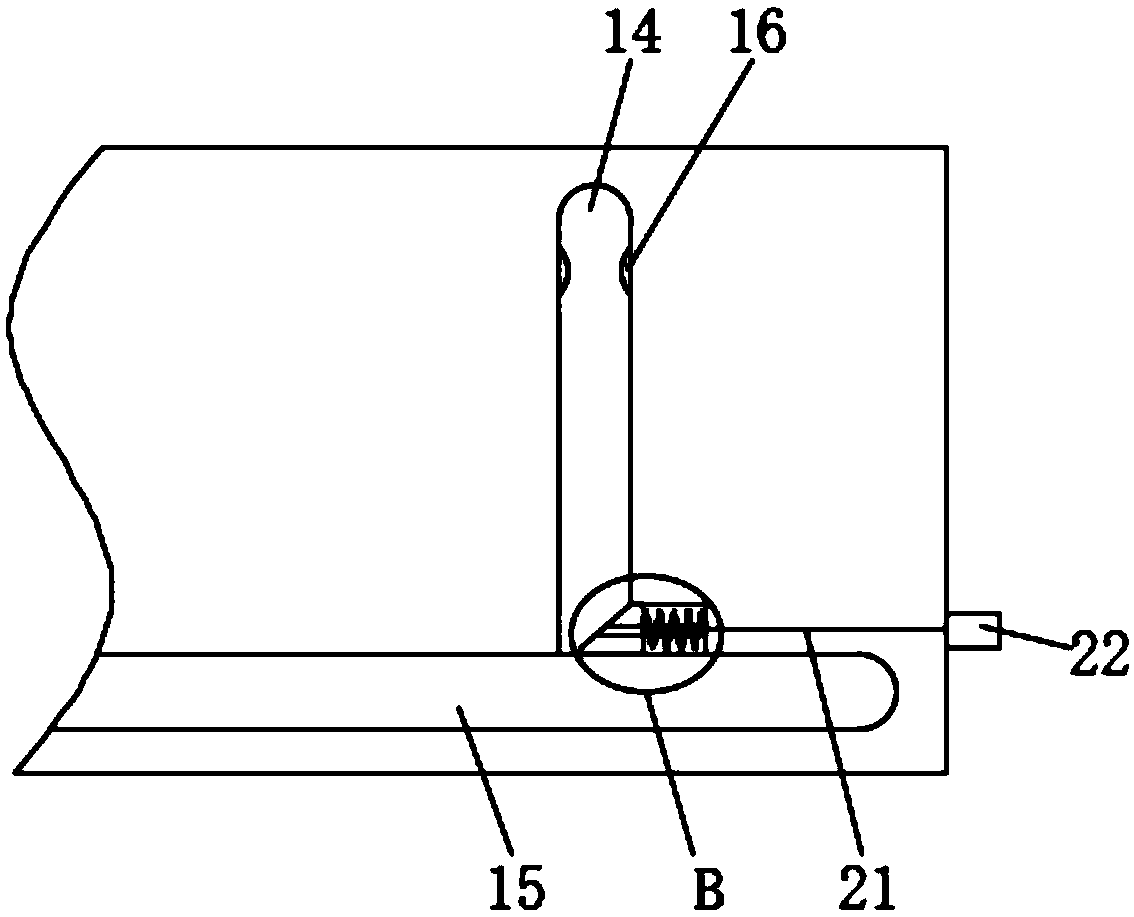

[0026] refer to Figure 1-5 , a glass-to-glass bonding device based on a capacitive touch screen, including a base 1 and a bonding table 2, the bonding table 2 is fixedly installed on the top wall of the base 1, and the top wall of the bonding table 2 is symmetrically opened. A plurality of countersunk holes, the inner bottom wall of each countersunk hole is equipped with a connecting bolt 3, and the connecting bolt 3 runs through the fitting platform 2 and is threaded with the base 1, and the base 1 and the fitting platform 2 are installed and Fixed to improve the stability of the bonding table 2.

[0027] Both ends of the laminating platform 2 are movably inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com