Forming structure on packaging bag production device

A technology of production device and forming structure, applied in packaging, transportation packaging, multiple packages, etc., can solve the problems of packaging bag wrinkles, uneven sealing edges on three sides, and inability to seal, and achieve neat packaging bag edges, sealing and cutting. Smooth and reduce the effect of equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

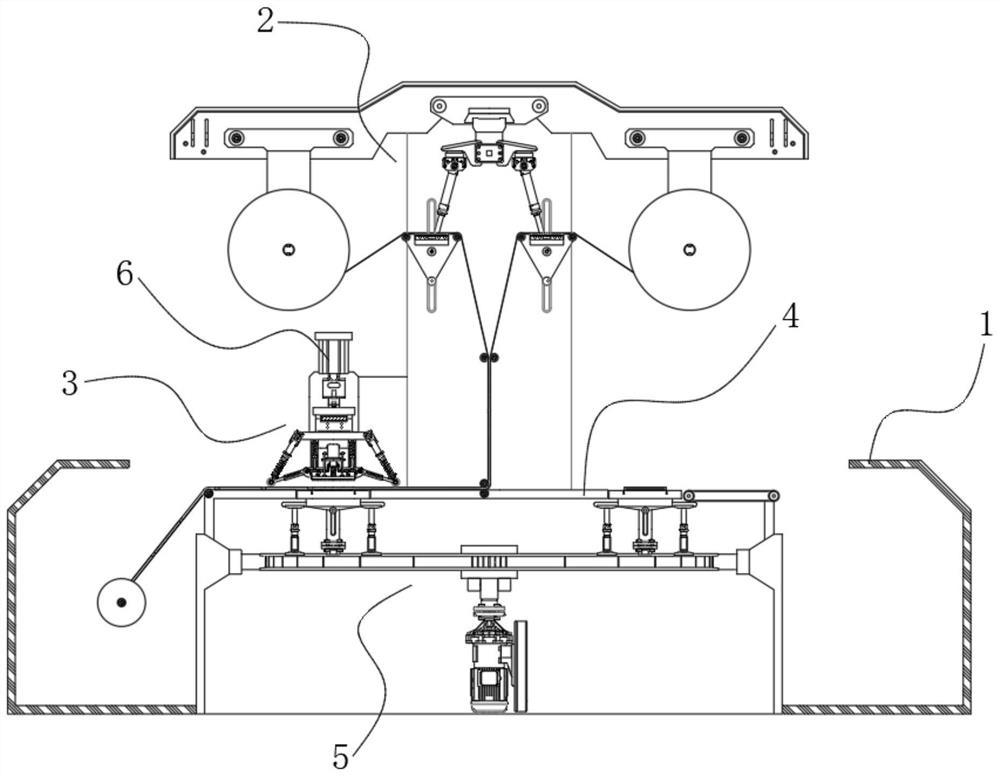

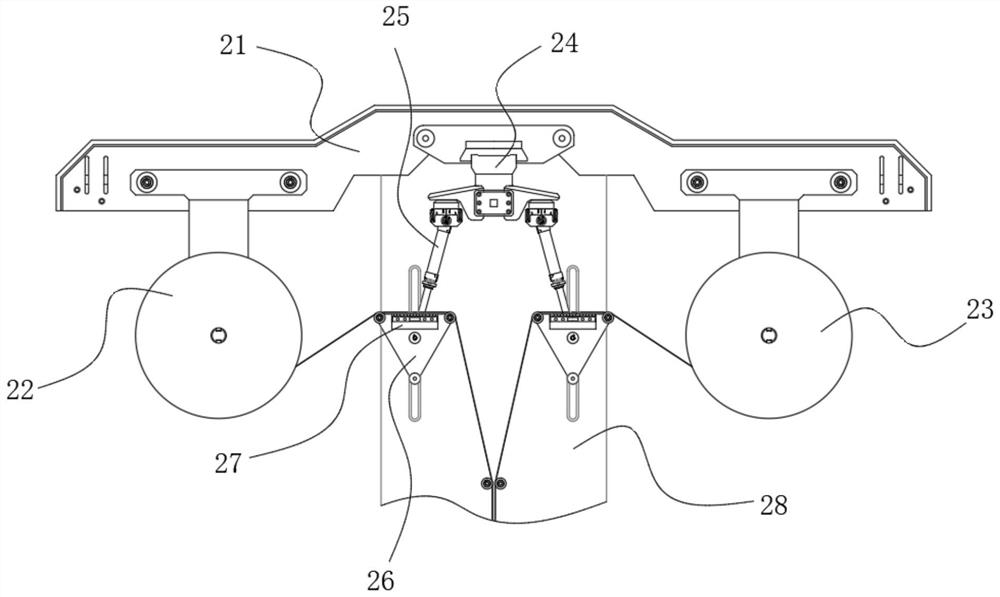

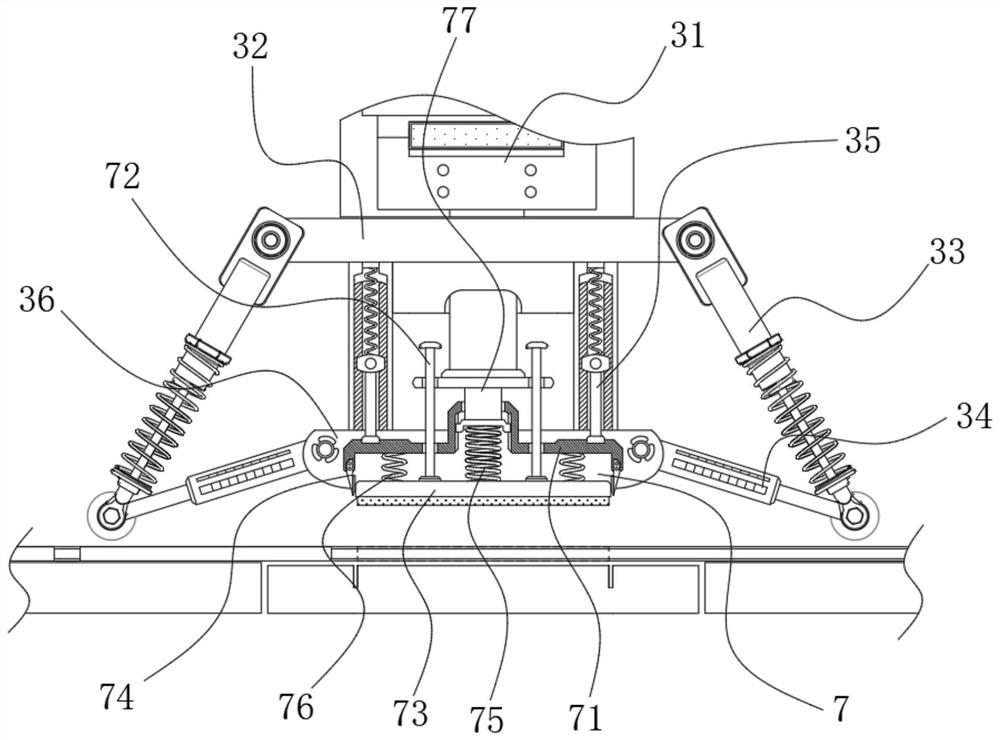

[0028] refer to figure 1 , the present invention provides a technical solution: a forming structure on a packaging bag production device, which includes a housing frame 1, a tensioning device 2, a sealing device 3, a supporting plate 4, a conveying device 5 and a main elevator 6, the The tensioning device 2 is arranged above the housing frame 1 to fix the packaging roll film and adjust the tension of the film. The housing frame 1 is arranged at the bottom end, and the support plate 4 is fixed on the upper end surface of the housing frame 1 above, and the support plate 4 is provided with a square hole, arranged in multiple groups in a circular arrangement, the sealing device 3 is arranged directly above the square hole on the left side, and the main elevator 6 drives the sealing device 3 to press down and up as a whole The packaging film is heat-sealed and cut, and the conveying device 5 is arranged under the support plate 4 to rotate and convey the packaging bag, and the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com