Double-plex extrusion linkage production line with turnover device

A technology of linkage production line and turning device, applied in tires, other household appliances, household appliances, etc., can solve the problems of reducing production line speed, long extrusion time, high viscosity of wear-resistant adhesive, and improve the quality of lamination and improve production efficiency. , The effect of reducing the extrusion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

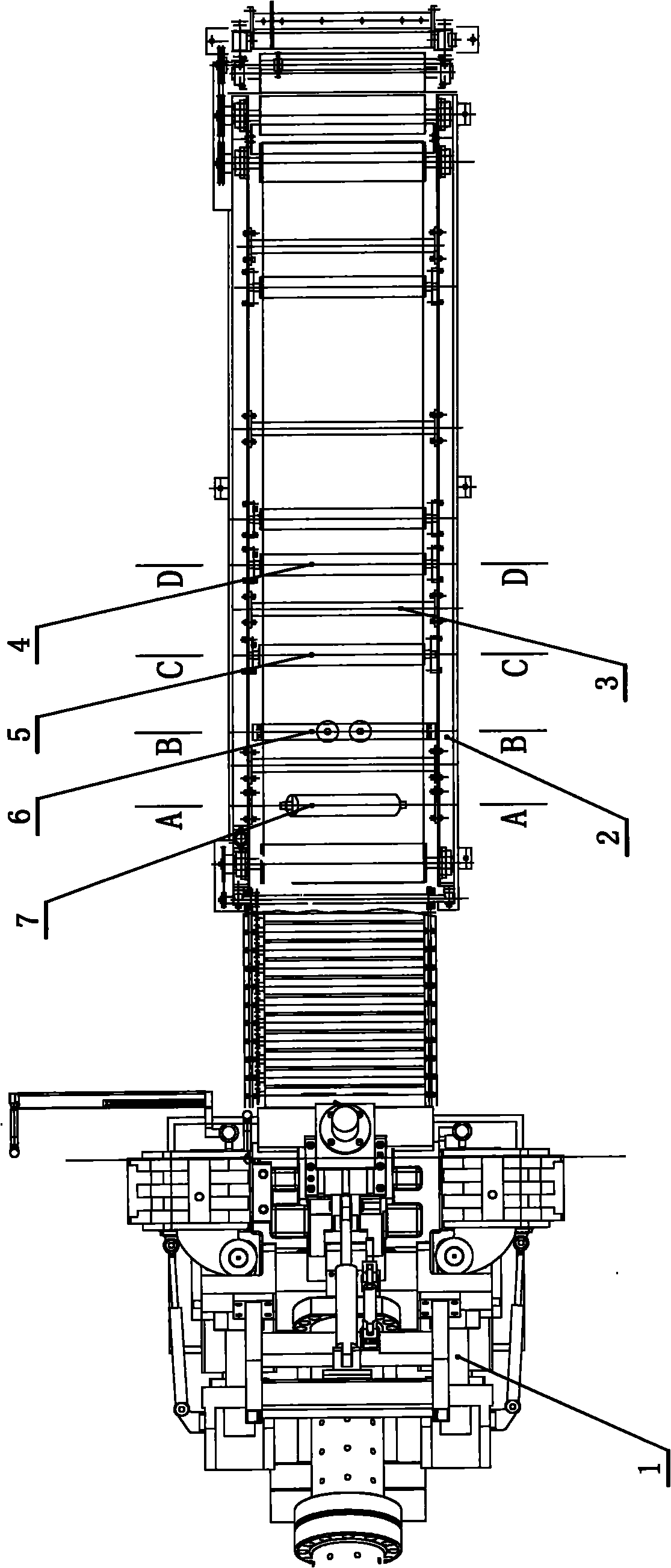

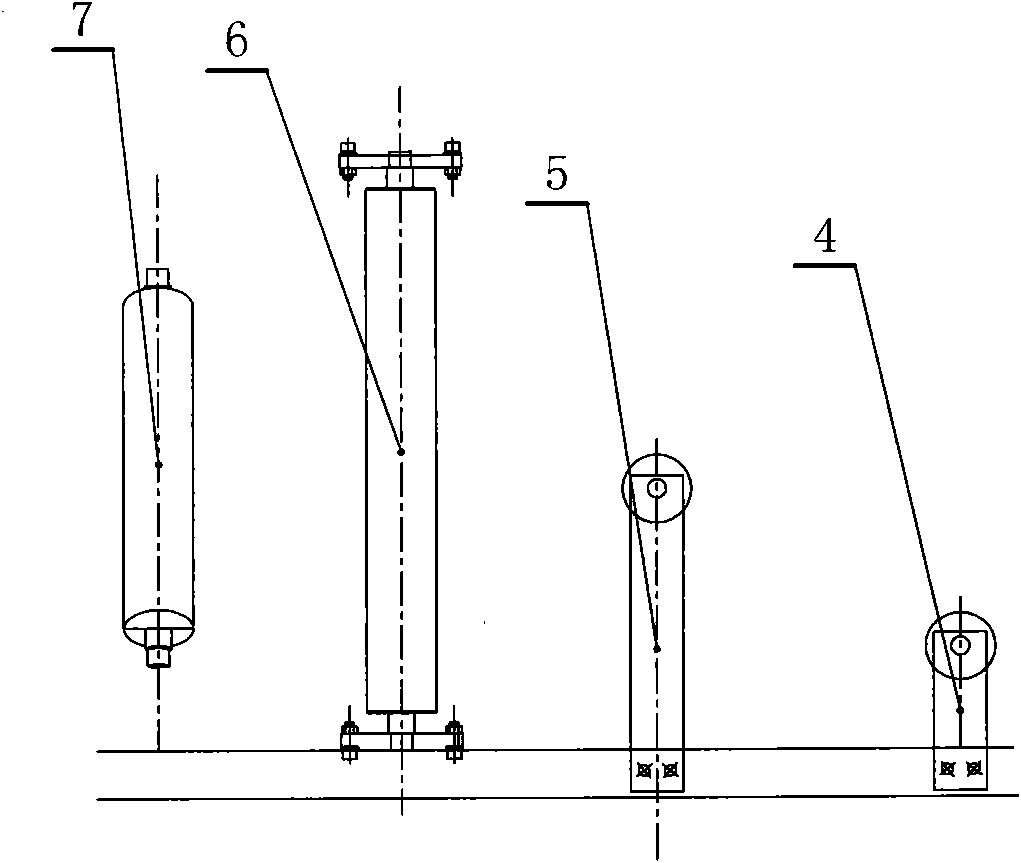

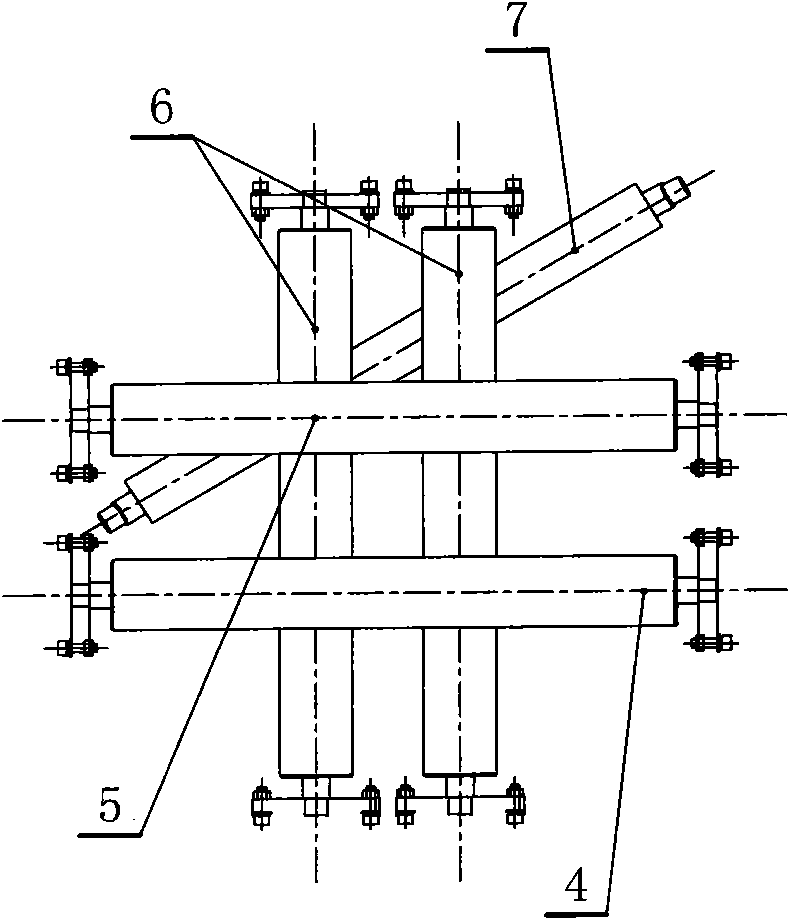

[0032] A double compound extrusion linkage production line with a turning device, such as figure 1 , figure 2 , image 3 As shown, it includes a double compound extruder unit 1, and the double compound extruder unit 1 includes a first extruder, a second extruder and a compound head, and the rear side of the compound head is provided with a track 2, which is opposite on the track 2. The take-up roller 3 is connected by rotation, and the track 2 on the rear side of the composite machine head is sequentially installed with a pre-turning roller 7, a turning roller 6, a leveling roller 5, a pressure roller 4, a pre-turning roller 7, a turning roller 6, Both the leveling roller 5 and the pinch roller 4 are located above the receiving roller 3, the pre-turning roller 7 is arranged obliquely, the turning roller 6 is vertically arranged, the leveling rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com