Glue laminating machine

A technology of laminating machine and water glue, which is applied in the direction of lamination device, control lamination, lamination, etc., can solve the problems of low lamination cycle, low degree of automation, and poor lamination quality, so as to improve lamination accuracy and The effect of fit quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

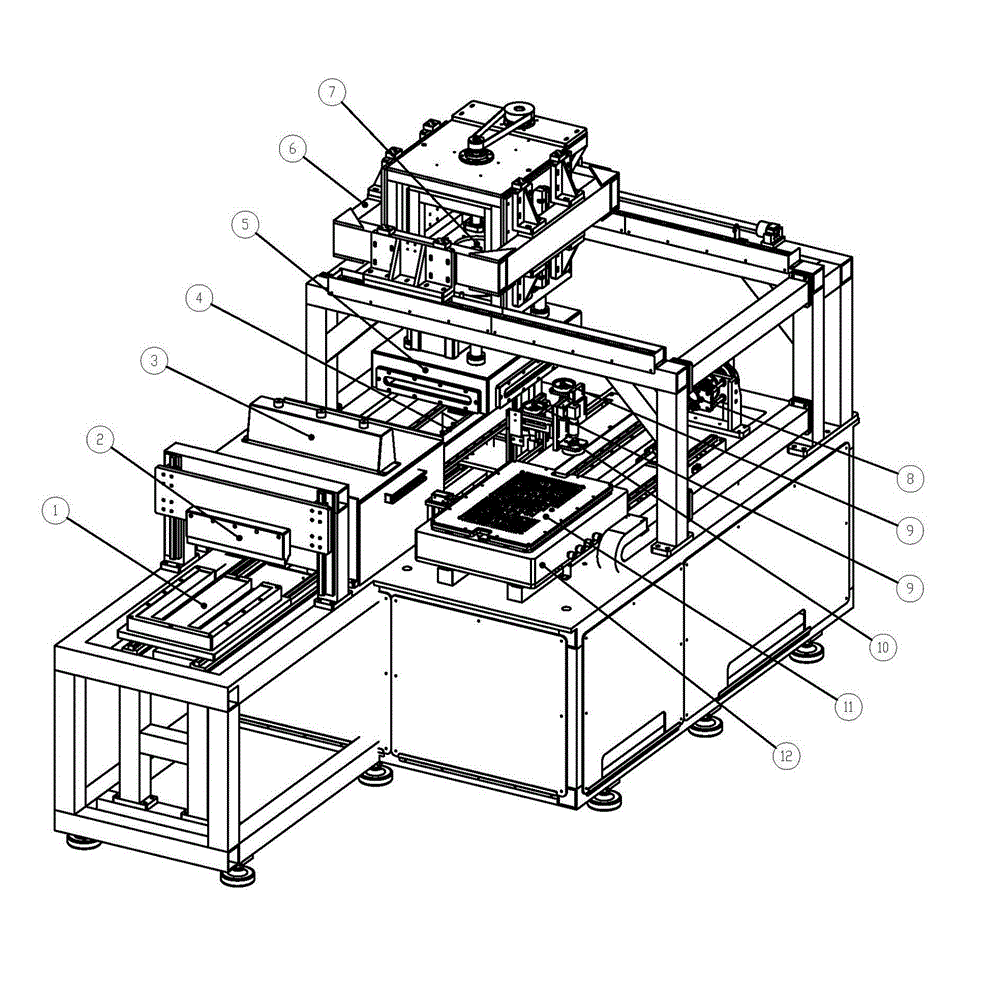

[0018] figure 1 The reference numerals in the figure are: upper panel coating fixture 1; water glue coating head 2; ultraviolet pre-curing light source 3; manipulator 4; vacuum upper chamber 5; upper panel X-axis transmission mechanism 6; rotation deviation compensation mechanism 7; The lower panel vacuum interface 8; the upper panel CCD image sensor 9; the lower panel CCD image sensor 10; the lower panel jig 11; the lower vacuum chamber 12.

[0019] Such as figure 1 Shown, a kind of water-glue bonding machine comprises frame, and described frame is preferably rigid frame, and described frame is provided with upper panel Y-axis transmission mechanism, lower panel Y-axis transmission mechanism, manipulator 4, upper panel The X-axis transmission mechanism 6, the Z-axis bonding mechanism, the upper panel CCD image sensor 9 and the lower panel CC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com