Wear-resistant cloth

A fabric and monofilament technology, applied in the field of wear-resistant fabrics, can solve the problems of light degradation and yellowing of polyamide fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

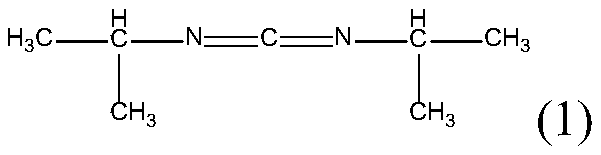

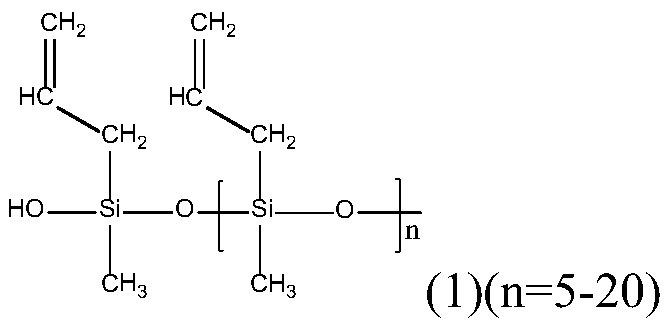

[0075] The base polymer was commercially available poly(trimethylene terephthalate) (component a)) to which 12 wt. % of thermoplastic elastomer polyurethane TPE was gravimetrically added to 80 wt. U (component b)), 6% by weight of a copolymer of polysiloxane of formula (1-1) and acrylate monomer (component c)), and 2% by weight of N,N'-di isopropylcarbodiimide (component d)).

[0076]

[0077] The polymer mixture is melted at 250°C to 270°C in the extruder, pressed into the spinning assembly by a gear pump, and then spun in a water bath at 68°C. Multiple stretches are performed under heat while heat setting and then the monofilament is wound.

[0078] Thus monofilaments obtained with a nominal diameter of 1.18 mm have the following textile values:

[0079] Diameter: 1.194mm

[0080] Linear density: 20000dtex

[0081] Free heat shrinkage 180°: 20.2%

[0082] Line strength: 35.4cN / tex

[0083] Nodule Strength: 30.6cN / tex

[0084] Interlocking strength: 33.9cN / tex

[0...

Embodiment 2

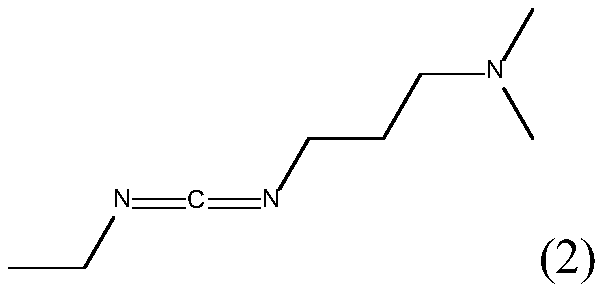

[0087] The base polymer is a commercially available 4:1 blend of polytrimethylene terephthalate and polytrimethylene naphthalate (component a)) gravimetrically to 85% by weight before the extruder Add 10% by weight of thermoplastic elastomer styrene block copolymer (TPE-S) (component b)) in the raw material, 2.5% by weight of polysiloxane and acrylate monomer of structural formula such as (2-1) copolymer (component c)), and 2.5% by weight of N,N'-diisopropylcarbodiimide (component d)).

[0088]

[0089] The polymer mixture is melted at 250°C to 270°C in the extruder, pressed into the spinning assembly by a gear pump, and then spun in a water bath at 68°C. Multiple stretches are performed under heat while heat setting and then the monofilament is wound.

[0090] The performance qualities of the monofilaments obtained are listed in Table 1 below.

Embodiment 3

[0092] Repeat Example 2, the base polymer is commercially available polytrimethylene naphthalate raw material (component a)), thermoplastic elastomer polyurethane (TPE-U) (component b)), polysiloxane with hydroxyl (formula (3-1)) and hydroxyl-containing acrylate generate graft copolymer (component c) through condensation reaction), 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt salt (component d)). The amount of each component is the same as in Examples.

[0093]

[0094]The performance qualities of the monofilaments obtained are listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com