Diesel engine injector water spacer extractor

A technology for diesel engines and fuel injectors, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of wasting material resources, time-consuming and labor-intensive, and labor-intensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

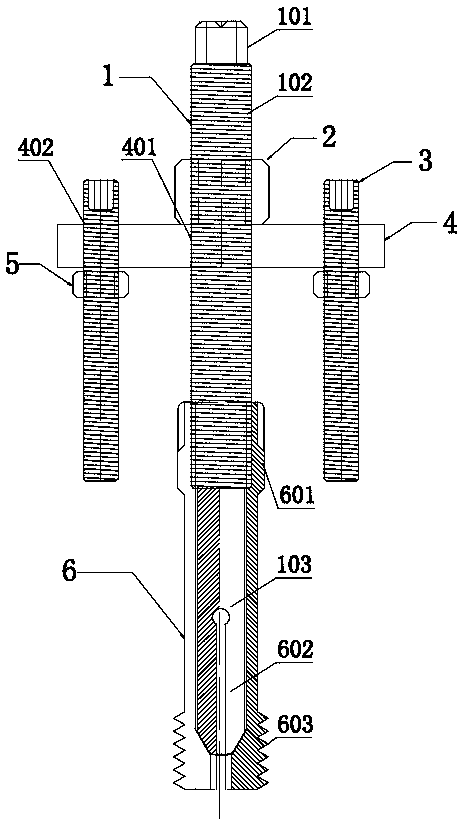

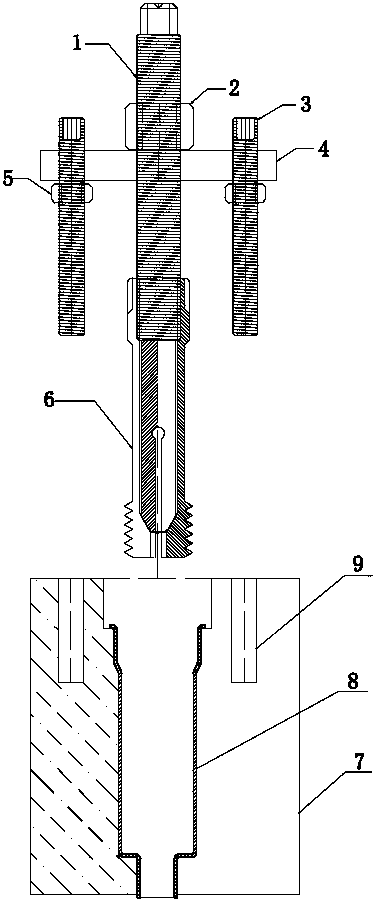

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

[0020] Such as Figure 1-2 As shown, the diesel engine injector water separator sleeve remover includes a support beam 4 and a support screw 3. The support beam 4 is provided with a central screw hole 401, and supports are respectively provided on both sides of the central screw hole 401. Screw hole 402, the central screw hole 401 is used to install the jacking screw 1, the jacking screw 1 is provided with an external thread, the external thread is matched with the internal thread of the support beam 4 center screw hole 401, and the support screw hole 402 is used for installing The support screw 3 is inserted into the support screw hole 9 corresponding to the cylinder head 7, so that the support beam 4 and the cylinder head 7 are fixed, and the water-proof sleeve 8 is conveniently taken out, and the support nut 5 is set on the support screw 3 for Fixed support beam 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com