Tiebar fixing device for die casting machine and die casting machine including same

A technology for fixing devices and die-casting machines, which is applied in the fields of die-casting machines and Corinthian column fixing devices. It can solve problems such as parts matching and transmission errors, and achieve the effect of improving the tightness of fitting and improving the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

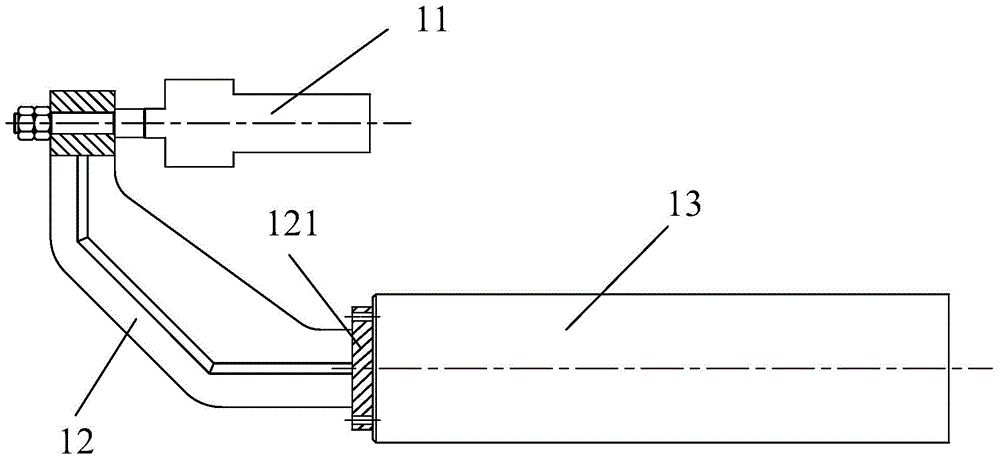

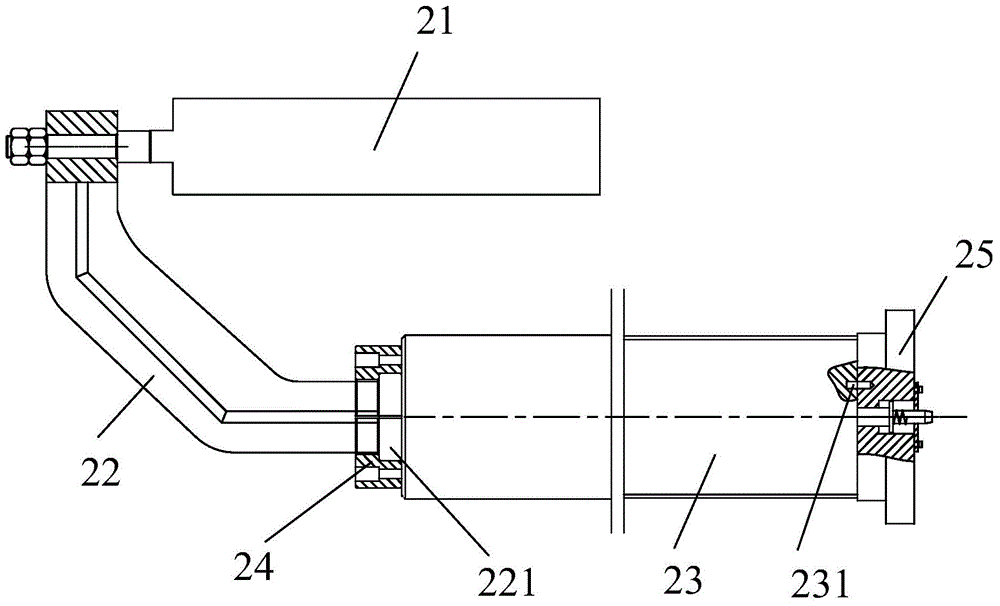

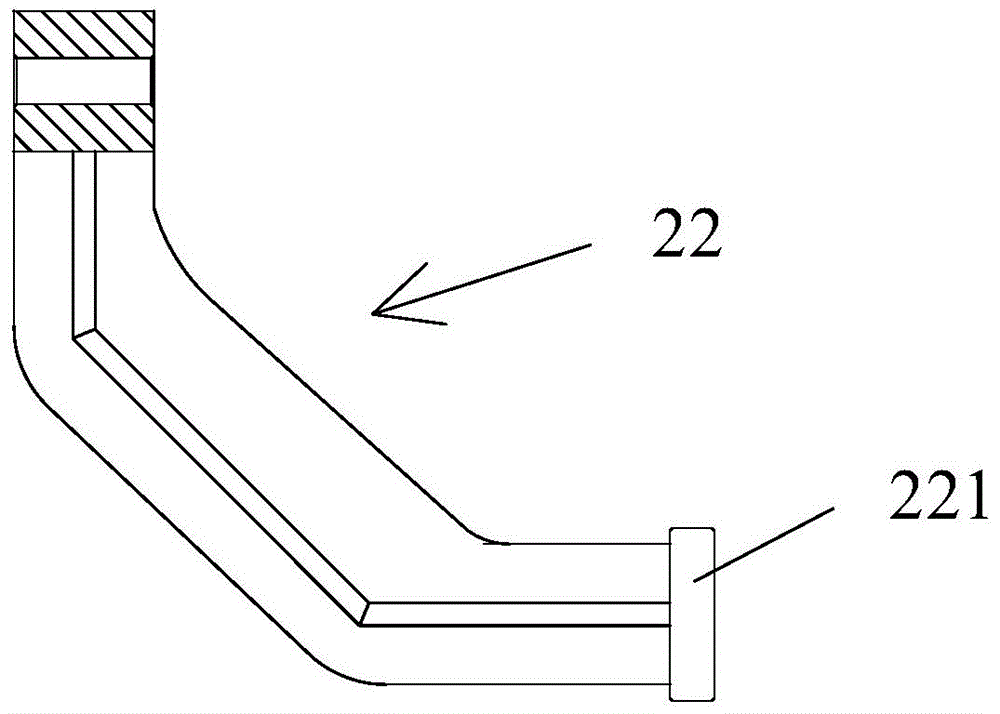

[0019] like figure 2 and image 3 As shown, a Coring post fixing device for a die-casting machine includes a support base assembly 22, one end of the support base assembly 22 is connected to an oil cylinder assembly 21, and the other end is provided with a connecting portion 221, and the support base assembly 22 The other end is connected to the Corinth post 23 through the connecting portion 221, the outer edge of the connecting portion 221 protrudes from the outer edge of the other end of the support seat assembly 22, and the Coring post fixing device also includes a gland 24, the gland 24 is provided with a stepped through hole, the other end of the support seat assembly 22 and the connecting portion 221 are penetrated through the stepped through hole of the gland 24 and are in clearance fit with the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com