SiC-substrate-based perpendicular structural GaN-based ultraviolet LED (Light Emitting Diode) and production method thereof

A vertical structure and substrate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult substrate peeling, high resistance of n-AlGaN layer, poor current dispersion, etc., to improve light extraction efficiency and good heat dissipation Ability, the effect of solving technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a GaN-based ultraviolet LED with a vertical structure based on a SiC substrate of the present invention specifically comprises the following steps:

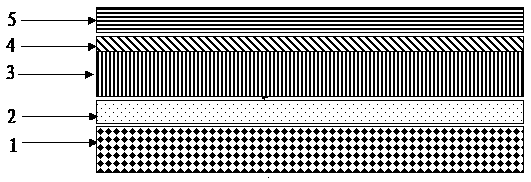

[0027] Step 1: Use metal organic chemical vapor deposition (MOCVD) to epitaxially grow a buffer layer 2, an n-AlGaN layer 3, a UV-luminescent multiple quantum well layer 4, and a p-GaN layer 5 on a SiC substrate 1 in order to obtain a GaN-based UV LED structure, see figure 1 . The ultraviolet light-emitting multiple quantum well layer 4 is composed of one or more of AlGaN containing Al components, AlInN and AlInGaN containing Al and In components capable of emitting ultraviolet light, and the emission wavelength of the ultraviolet light is adjustable.

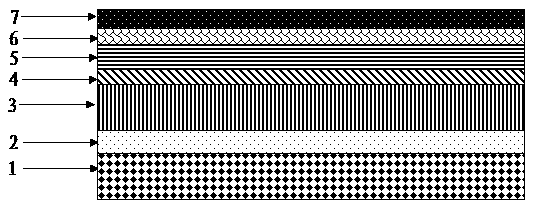

[0028] Step 2: sequentially prepare the ohmic reflective layer 6 and the metal bonding layer 7 on the p-GaN layer 5, see figure 2 ; The ohmic reflective layer 6 can be made of silver and its compounds, and the metal bonding layer 7 can be made of m...

Embodiment 1

[0033] A method for preparing a GaN-based ultraviolet LED with a vertical structure based on a SiC substrate of the present invention comprises the following steps:

[0034] Step 1: Using metal-organic chemical vapor deposition (MOCVD), AlN is used as a buffer layer 2 on a SiC substrate 1 to epitaxially produce an N-type AlGaN film with a high Al composition, and then grow multiple AlGaN quantum wells and p-GaN in sequence The thin film forms the epitaxial structure of the UV LED.

[0035] Step 2: Evaporate an ohmic reflective layer 6 of Ag / Ti / Au material on the p-GaN layer 5 by using electron beam evaporation equipment, and then evaporate an Au / Sn metal bonding layer 7 .

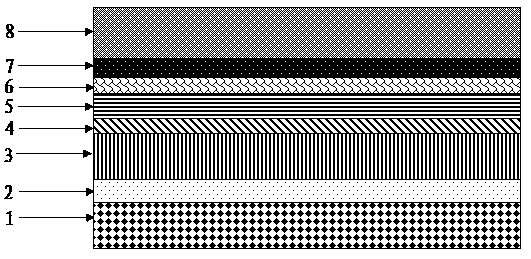

[0036] Step 3: The device is bonded to the Cu / W alloy substrate 8 with the plating layer as the contact surface through a bonding machine.

[0037] Step 4: Use the substrate thinning technology to thin the SiC substrate 1 to less than 100 microns, and then use ICP to etch the SiC substrate 1 and the buffer...

Embodiment 2

[0040] A method for preparing a GaN-based ultraviolet LED with a vertical structure based on a SiC substrate of the present invention comprises the following steps:

[0041] Step 1: Use metal-organic chemical vapor deposition (MOCVD) to epitaxially form an N-type AlInGaN film with a high Al composition on the SiC substrate 1 with AlN as a buffer layer 2, and then grow AlInGaN multiple quantum wells and p-type GaN films in sequence An LED epitaxial structure is formed.

[0042] Step 2: Evaporate an ohmic reflective layer 6 of Ag / Ti / Au material on the p-GaN layer 5, and then evaporate an Au / Sn metal bonding layer 7.

[0043] Step 3: bonding the above-mentioned epitaxial wafer to the Si substrate.

[0044] Step 4: The SiC substrate 1 and the buffer layer 2 are removed by a combination of physical grinding and plasma etching.

[0045]Step 5: Finally, an n-type electrode is prepared on n-type AlGaN to realize a vertical GaN-based ultraviolet LED.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com