Method for improving uniform distribution of light sources and structure thereof

A uniform distribution and light source technology, applied in the direction of light source, fixed light source, point light source, etc., can solve problems such as uneven light source and shadow, image shadow, and affecting the accuracy of system recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Its detailed description is as follows, and the preferred embodiment is only to illustrate the present invention by way of enumeration, but not to limit the present invention.

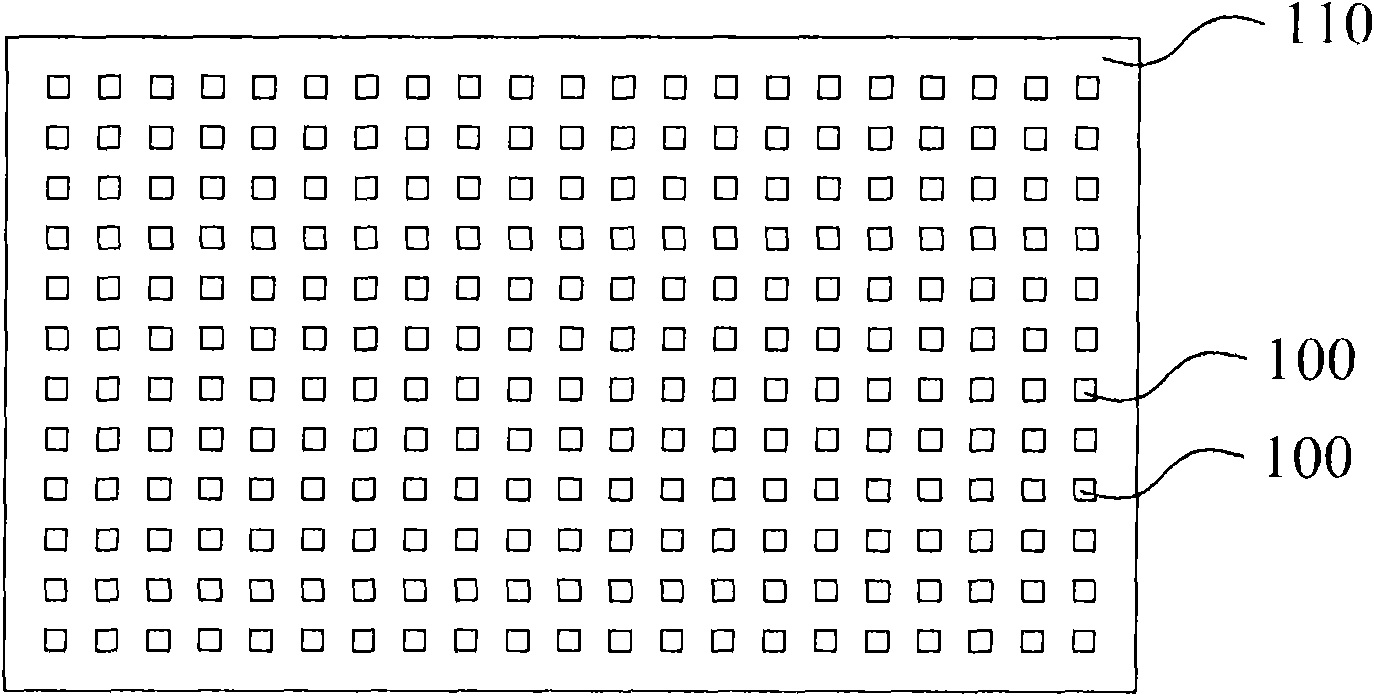

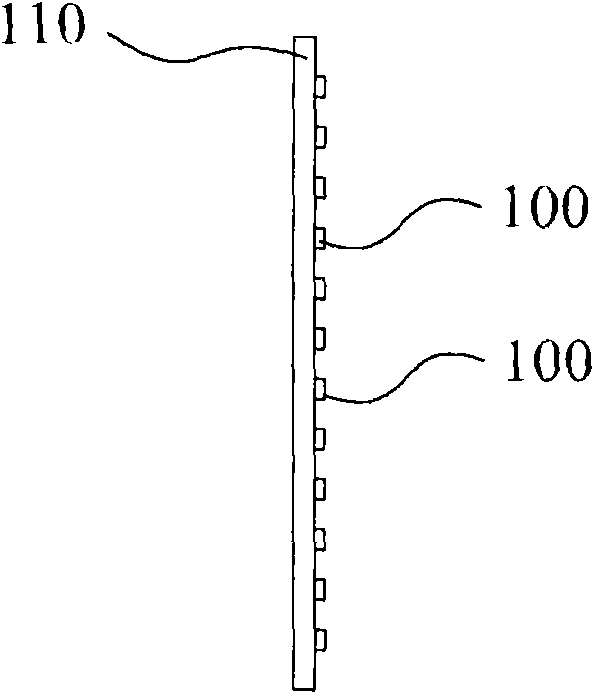

[0017] figure 2 It is a schematic flowchart of a method for improving uniform distribution of light sources according to an embodiment of the present invention. Such as figure 2 As shown, the method includes the following steps: providing a base with at least one curved surface (step S101); and disposing a plurality of light source chips on the curved surface (step S102). Wherein, the light source chip can be selected from a light emitting diode chip or a laser chip, and the laser chip can be a side-firing laser chip or a side-firing laser chip.

[0018] image 3 It is a schematic flow chart of a method for improving the uniform distribution of light sources according to an embodiment of the present invention. Step S103 is to arrange a plurality of light source chips on a curved surface, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com