Organic light emission diode device and fabrication method thereof

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low light-emitting performance, total reflection loss, and low transmittance of light-emitting devices, and achieve luminescence Excellent efficiency, increased light extraction efficiency, and high light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

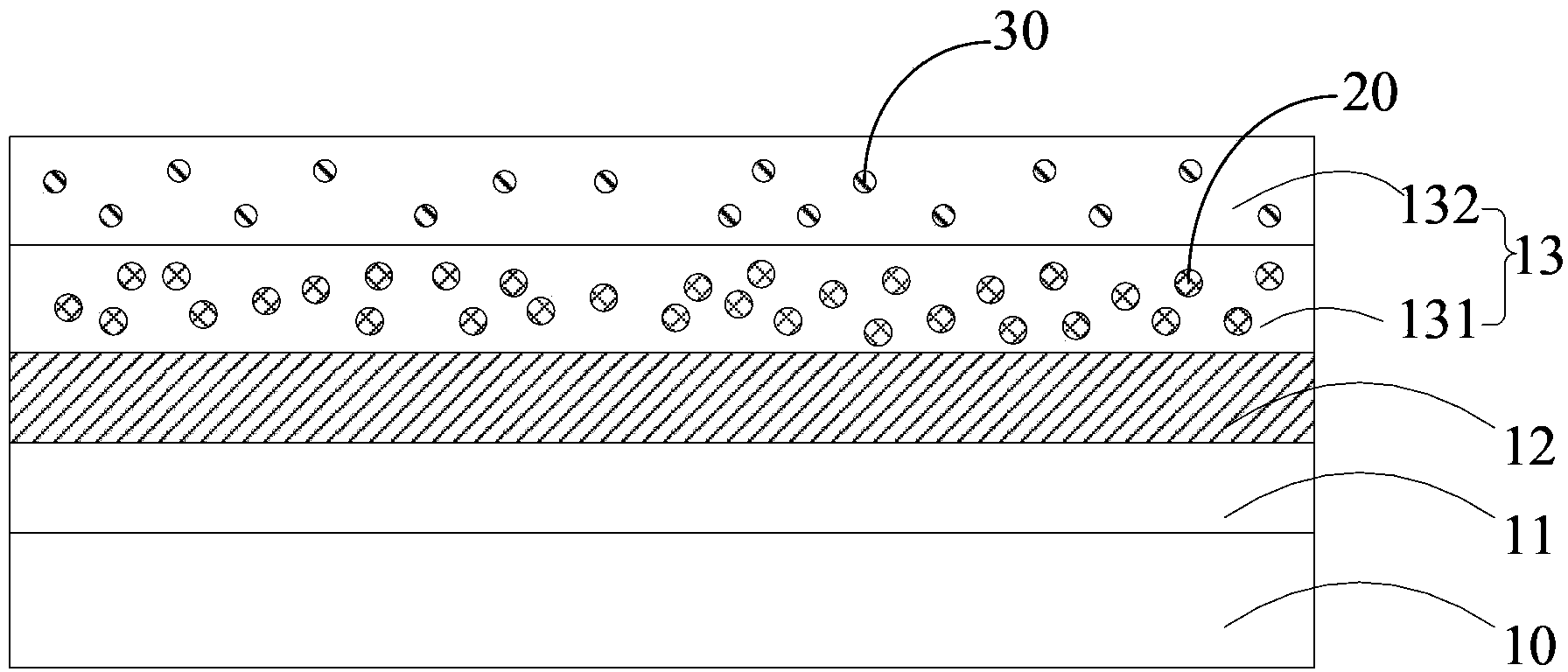

[0058] A method for preparing an organic electroluminescent device, comprising the following steps:

[0059] (1) Place a transparent glass substrate on a 1×10 -4 In the vacuum coating chamber of Pa, a metal Ag thin film with a thickness of 100nm is prepared on the surface of the substrate as an anode by means of vacuum thermal resistance evaporation;

[0060] (2) Prepare a light-emitting functional layer on the surface of the metal Ag thin film by vacuum thermal resistance evaporation, including a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, and an electron injection layer in sequence;

[0061] Among them, the hole injection layer is made of CuPc with a thickness of 20nm, the hole transport layer is made of NPB with a thickness of 30nm, and the light emitting layer is made of Alq 3 , the thickness is 15nm, and then the electron transport layer is made of TPBi with a thickness of 30nm, and the electron injection layer is ma...

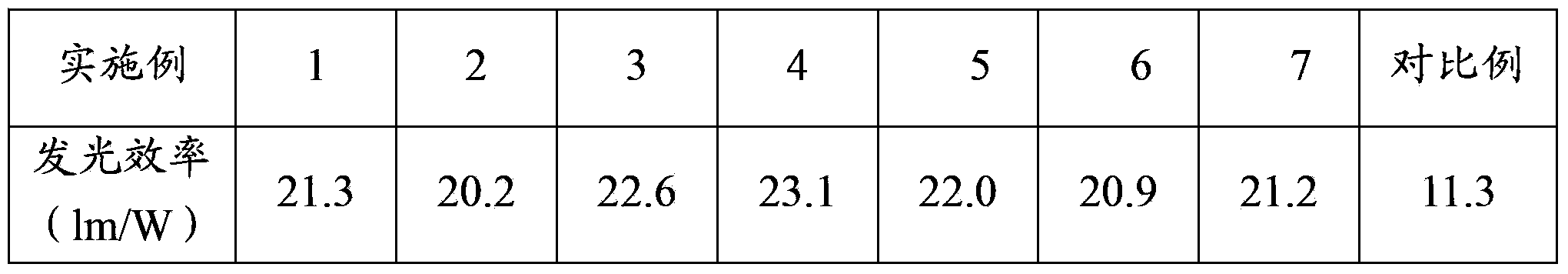

Embodiment 2

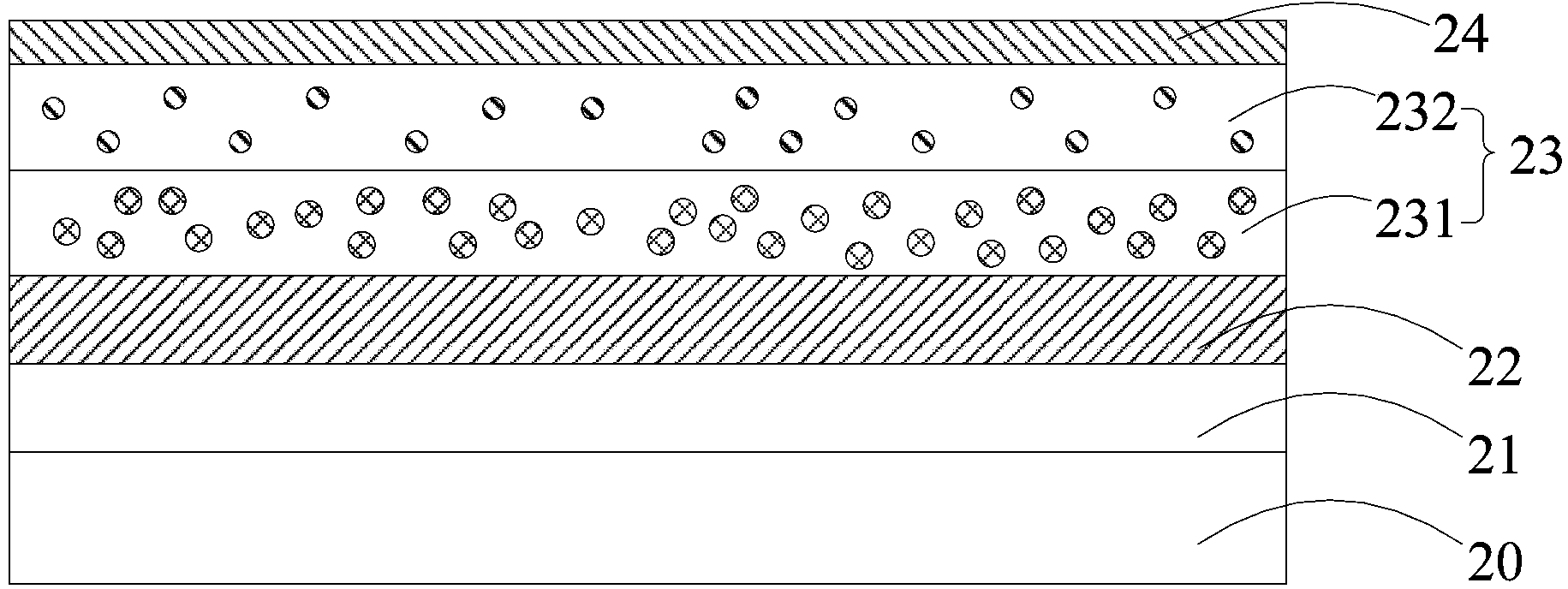

[0067] The difference between this embodiment and Embodiment 1 is that the thickness of the first doped layer is 40nm, and the SiO in the second doped layer 2 The mass ratio to metal Au is 10:100, namely SiO 2 The ratio of the evaporation rate to the metal Au is 10:100, where SiO 2 The evaporation rate of Au is 0.2nm / s, and the evaporation rate of Au is 2nm / s.

Embodiment 3

[0069] The difference between this embodiment and Embodiment 1 is that the thickness of the first doped layer is 40nm, and the SiO in the second doped layer 2 The mass ratio to metal Au is 100:100, namely SiO 2 The ratio to the evaporation rate of metal Au is 100:100, where SiO 2 The evaporation rate of Au is 1 nm / s, the evaporation rate of Au is 1 nm / s, and the thickness of the second doped layer is 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com