Organic light-emitting diodes and an arrangement with several organic light-emitting diodes

A light-emitting diode, organic technology, applied in the direction of organic semiconductor devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of high reflectivity, hindering the selection of substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] An embodiment of a blue emitting OLED includes the following layers:

[0064] 1 substrate, aluminum foil

[0065] 2 silver layers, sputtered

[0066] 3 Hole transport layer: Spiro-TTB, p-doped with 2% NDP-2, 25nm thick

[0067] 4 electron blocking layer, Spiro-TAD, 10nm

[0068] 5 emitter layer: blue emitter, 20nm

[0069] 6 electron transport layer, BPhen, 10nm

[0070] 7 Electron transport layer, BPhen, n-doped with Cs at a ratio of 1:1, 130nm

[0071] 8 transparent cathodes, Ag vapor deposited, 15nm

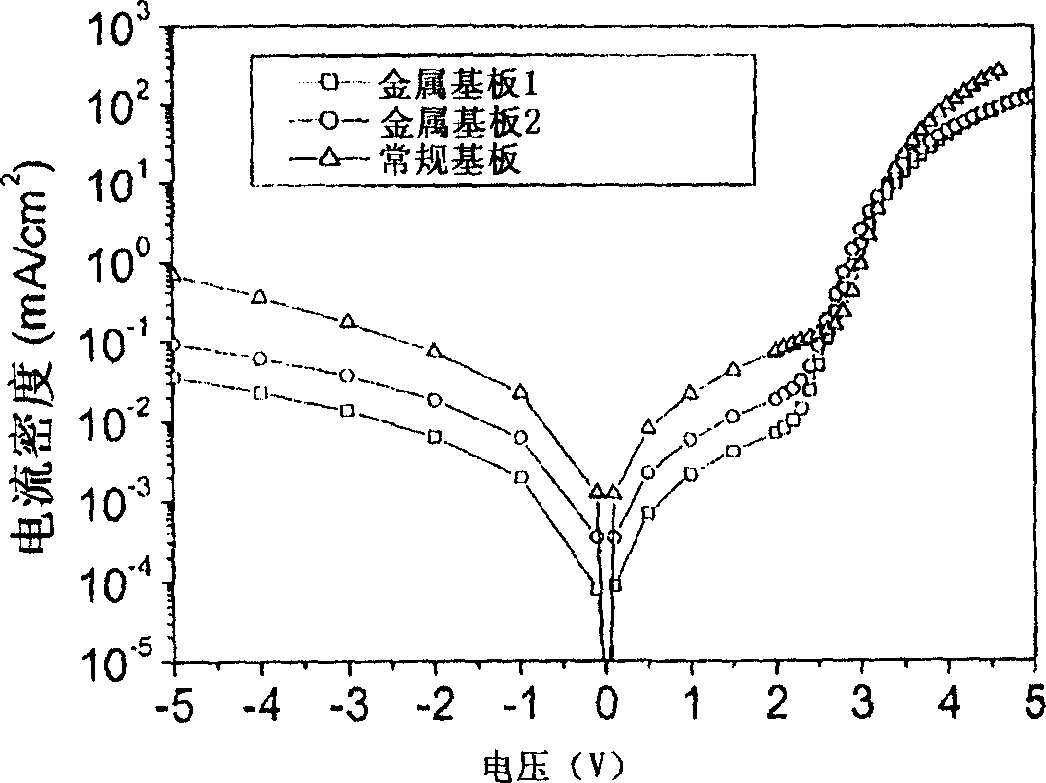

[0072] figure 1 The current-voltage characteristic curves (squares and circles) of two organic light-emitting elements of this type are shown; in comparison, a similar element realized on a high-quality glass substrate with clean room conditions is shown. The resulting Cr / Ag contacts. It is clear that these OLEDs have significantly better barrier characteristic curves. The surprising aspect here is that the effect requires only an unusually thick electron-trans...

Embodiment 2

[0074] An embodiment of a green emitting OLED comprises the following layers:

[0075] 10 substrates, aluminum foil

[0076] 11 silver layers, sputtered

[0077] 12 Hole transport layer: Spiro-TTB, p-doped with 2% NDP-2, 48nm thick

[0078] 13 electron blocking layer, Spiro-TAD, 10nm

[0079] 14 Emitter layer I, TCTA: Ir(ppy) 3 (9%), 5nm

[0080] 15 Emitter layer II, TPBI: Ir(ppy) 3 (9%), 10nm

[0081] 16 electron transport layer, BPhen, 10nm

[0082] 17 Electron transport layer, BPhen, n-doped with Cs at a ratio of 1:1, 130nm

[0083] 18 transparent cathodes, Ag vapor deposited, 15nm

[0084] 19 Overlay: Spiro-TTB, 90nm

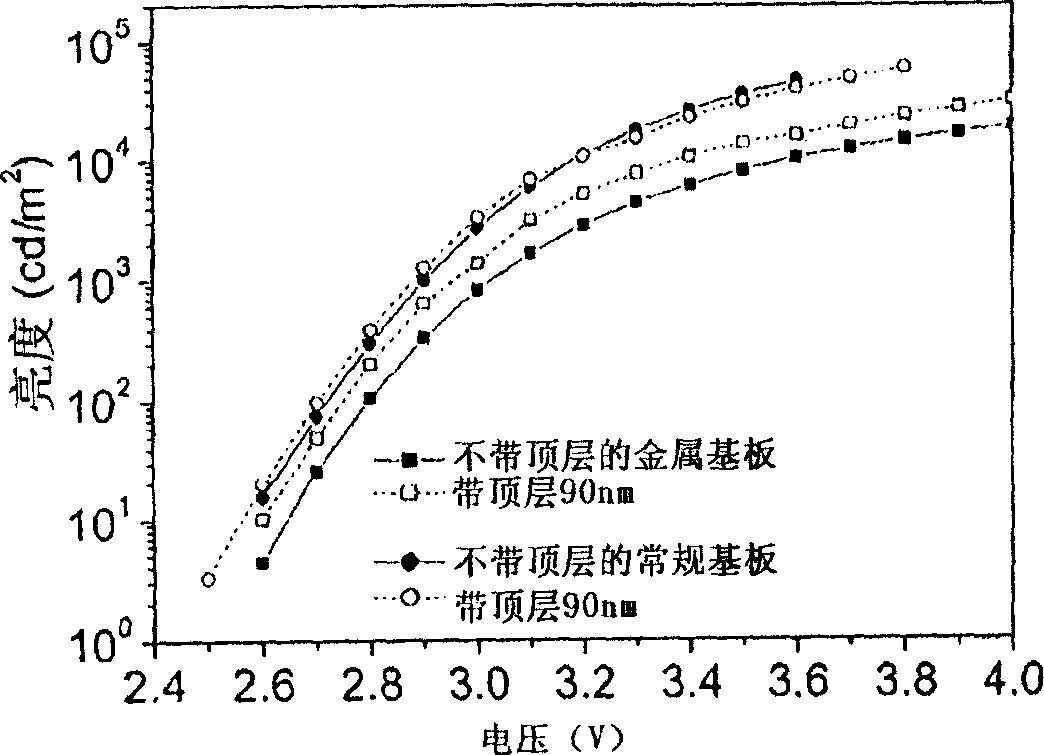

[0085] figure 2 The luminance-voltage characteristic curves of two organic light-emitting elements according to the second embodiment of the invention are shown (squares and circles, each with and without layer 19 ). 100Cd / m has been obtained at 2.9V 2 Brightness at 10,000Cd / m 2 The maximum performance efficiency is 501m / W. This demonstrates t...

Embodiment 3

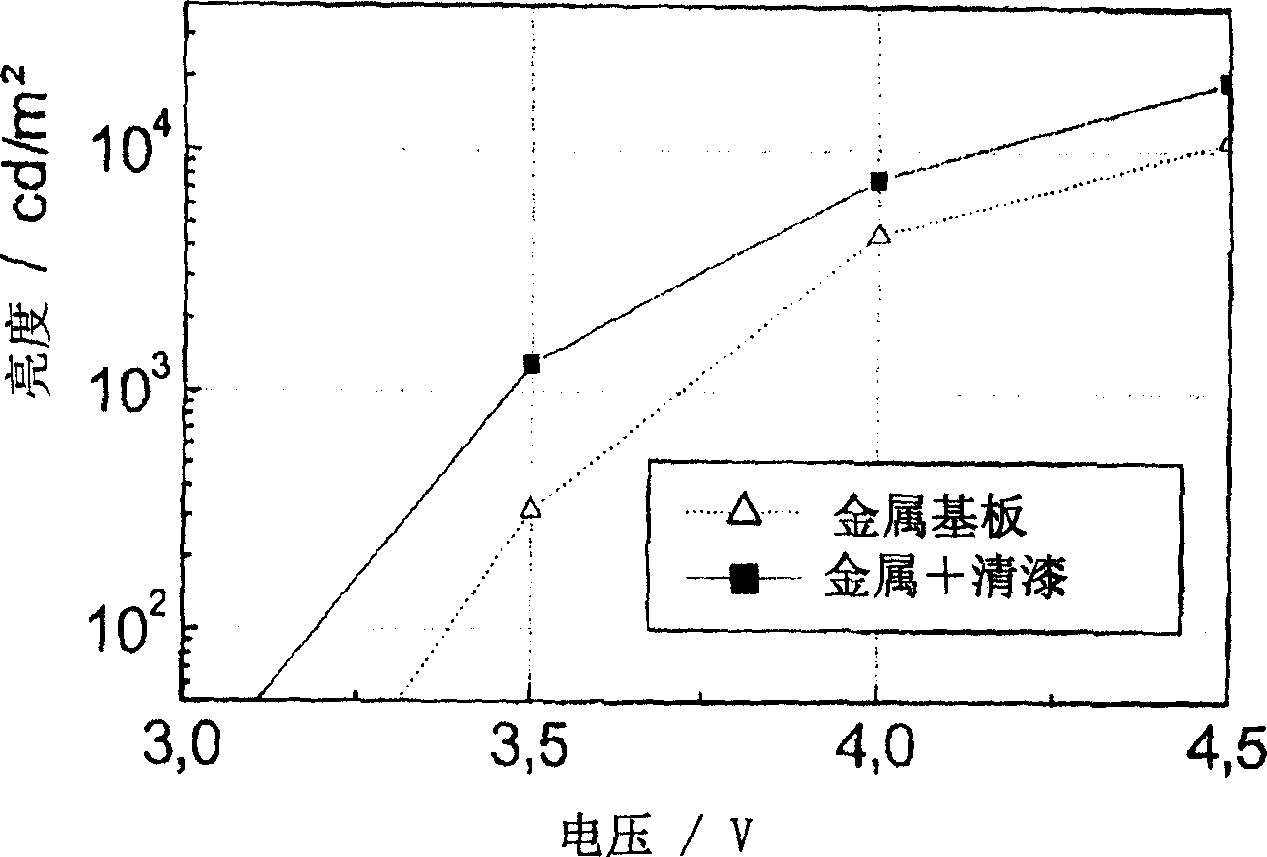

[0088] In Example 3, it is shown how an additional layer of varnish on a metal substrate contributes to lower leakage current and subsequently improved electrical performance. At the same time, a thick p-side is used, which helps to make the surface more uniform. For this purpose, image 3 Two OLEDs having structures similar in design, one formed with smoothing layer 21 and the other formed without smoothing layer 21 were compared.

[0089] 20 substrates, aluminum foil

[0090] 21 layers of smoothing, varnish (optional)

[0091] 22 silver layers, sputtered

[0092]23 Hole transport layer: MeO-TPD, p-doped with 4% F4-TCNQ, 150nm thick

[0093] 24 electron blocking layer, Spiro-TAD, 10nm

[0094] 25 luminescent layers, TCTA: Ir(ppy) 3 (8%), 20nm

[0095] 26 electron transport layer, BPhen, 10nm

[0096] 27 Electron transport layer, BPhen, n-doped with Cs at a ratio of 1:1, 30nm

[0097] 28 transparent cathodes, Ag vapor deposited, 15nm

[0098] From image 3 As can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com