Current diffusion electrode, semiconductor emitting device, method for manufacturing current diffusion electrode and method for manufacturing semiconductor emitting device

A technology of current diffusion and light-emitting devices, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that affect the light output power and brightness of light-emitting devices, p-type GaN cannot effectively break through, p-type GaN ohmic contact is difficult, etc. Achieve improved electrical properties, low forward voltage, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

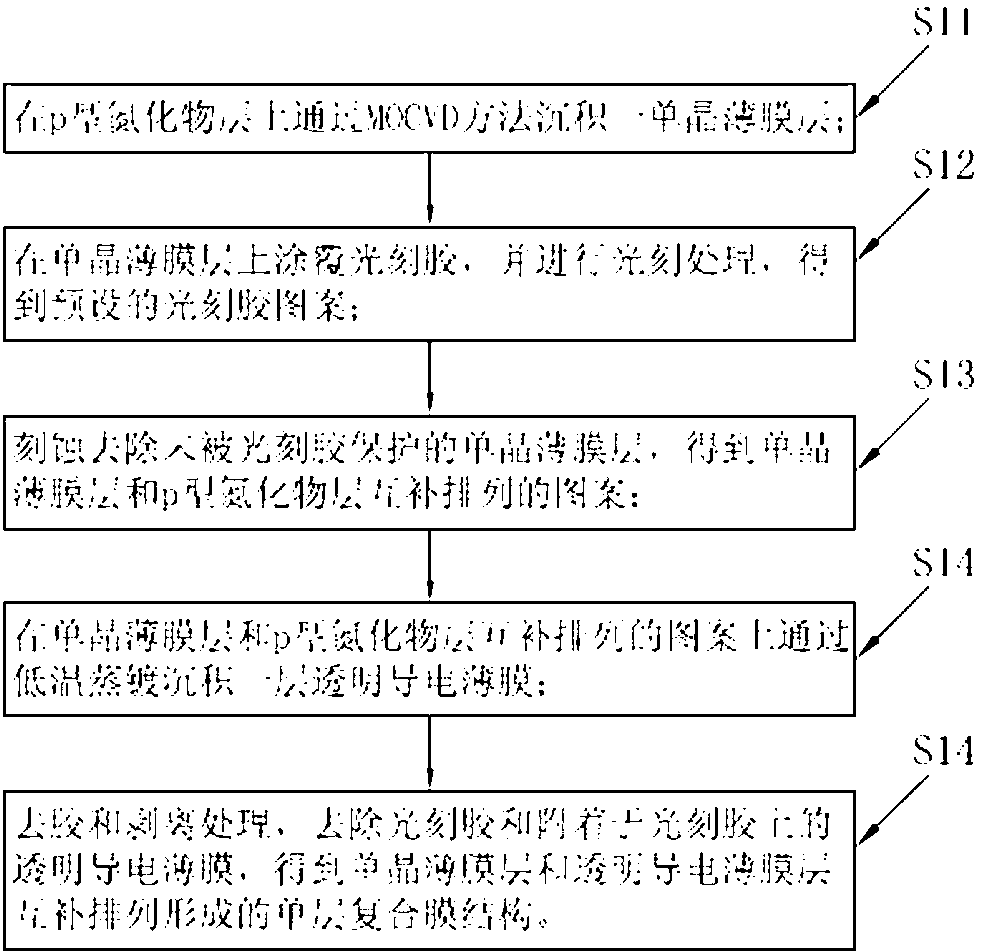

[0039] Please refer to figure 2 Shown, the present invention also provides a kind of preparation method of current spreading electrode, and described method comprises the following steps:

[0040] S11. Depositing a single crystal thin film layer on the p-type nitride layer by MOCVD method;

[0041] S12. Coating photoresist on the single crystal thin film layer and performing photolithography treatment to obtain a preset photoresist pattern;

[0042] S13. Etching and removing the single crystal thin film layer not protected by the photoresist to obtain a complementary arrangement pattern of the single crystal thin film layer and the p-type nitride layer;

[0043] S14. Depositing a layer of transparent conductive film by low-temperature evaporation on the pattern in which the single crystal thin film layer and the p-type nitride layer are complementary arranged;

[0044] S15 , stripping and stripping, removing the photoresist and the transparent conductive film attached to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com