Metal contact structure of two-dimensional semiconductor material and method thereof

A two-dimensional semiconductor and metal contact technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as large influence of properties, large contact resistance, energy level of band gap defects, etc., and achieve simple ohmic contact, Effect of small contact resistance and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A metal contact structure of a two-dimensional semiconductor material, comprising: a substrate, a metal electrode, and a two-dimensional semiconductor material;

[0031] A metal plug is formed over the substrate.

[0032] A metal contact method for a two-dimensional semiconductor material, the steps comprising:

[0033] S1. Depositing a layer of dielectric layer on the substrate, the thickness of the dielectric layer is not more than 0.1 mm;

[0034] S2. Two metal electrodes are arranged at the metal plug, and the two metal electrodes are kept parallel;

[0035] S3, further performing sulfuration treatment on the dielectric layer to form a two-dimensional transition metal compound film;

[0036] S4. A two-dimensional semiconductor material is arranged in the vulcanization treatment area of the dielectric layer, and the two-dimensional semiconductor material accounts for four-fifths of the vulcanization treatment area;

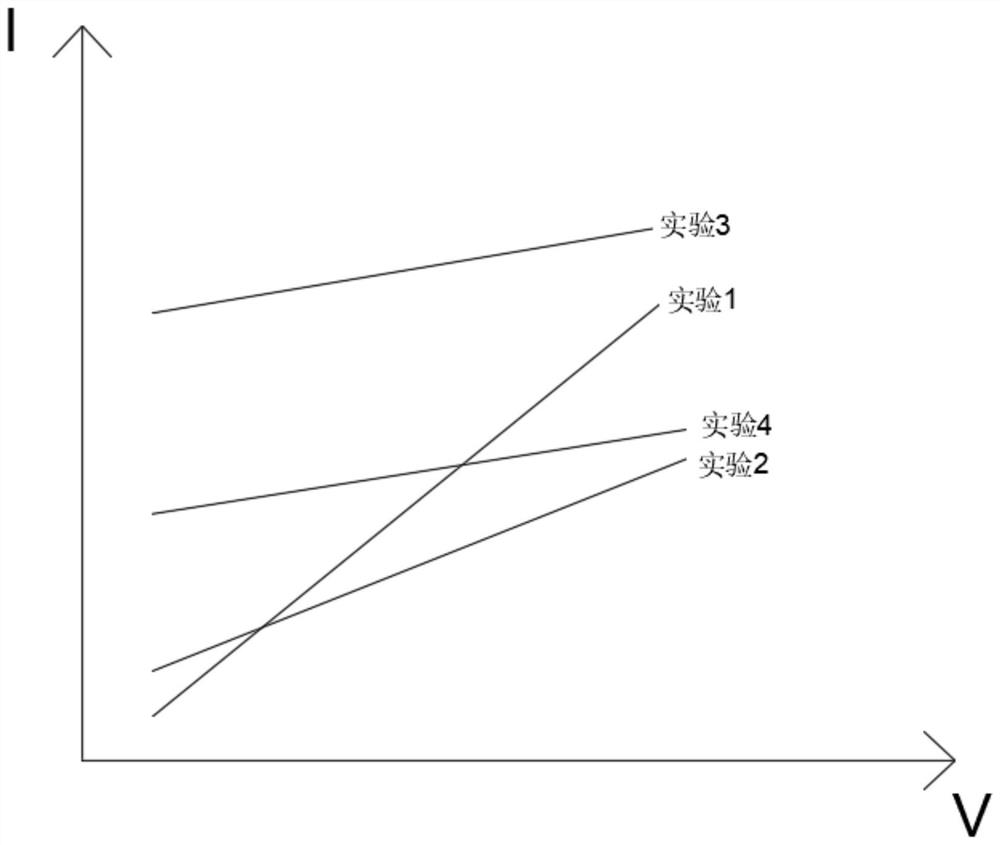

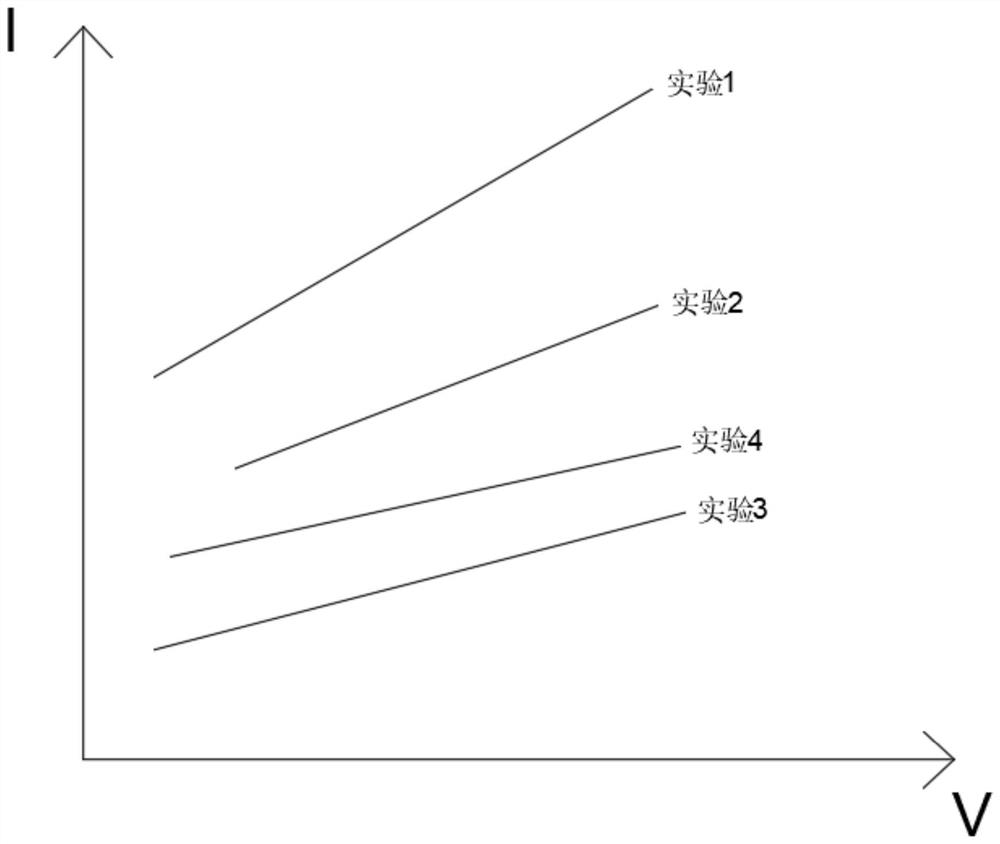

[0037] S5. Use the Kelvin method to calculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com