Organic electroluminescent device and preparation method thereof

An electroluminescent device and electroluminescent technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the mismatch of the refractive index of the anode material and the glass substrate, the low light-emitting efficiency of the OLED light-emitting device, and the transmission efficiency. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

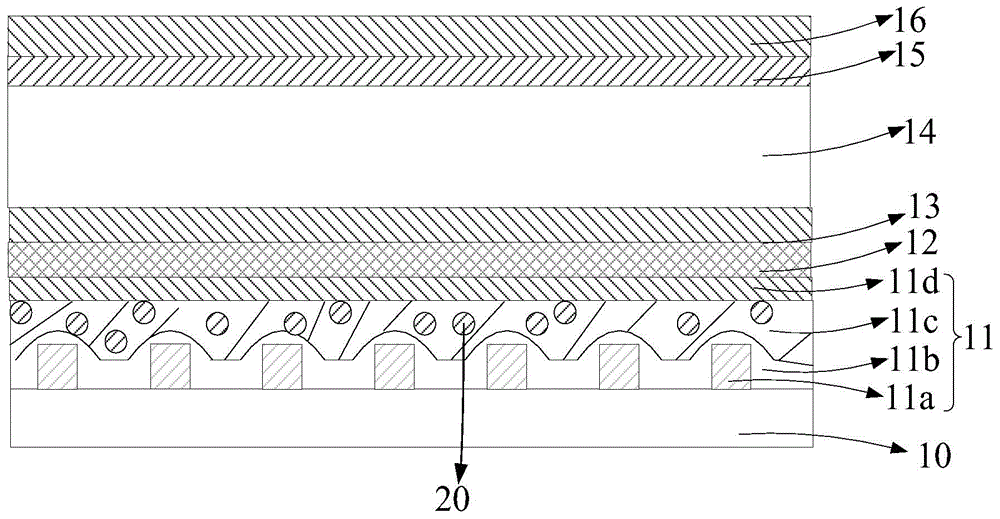

[0057] A method for preparing an organic electroluminescent device, comprising the following steps:

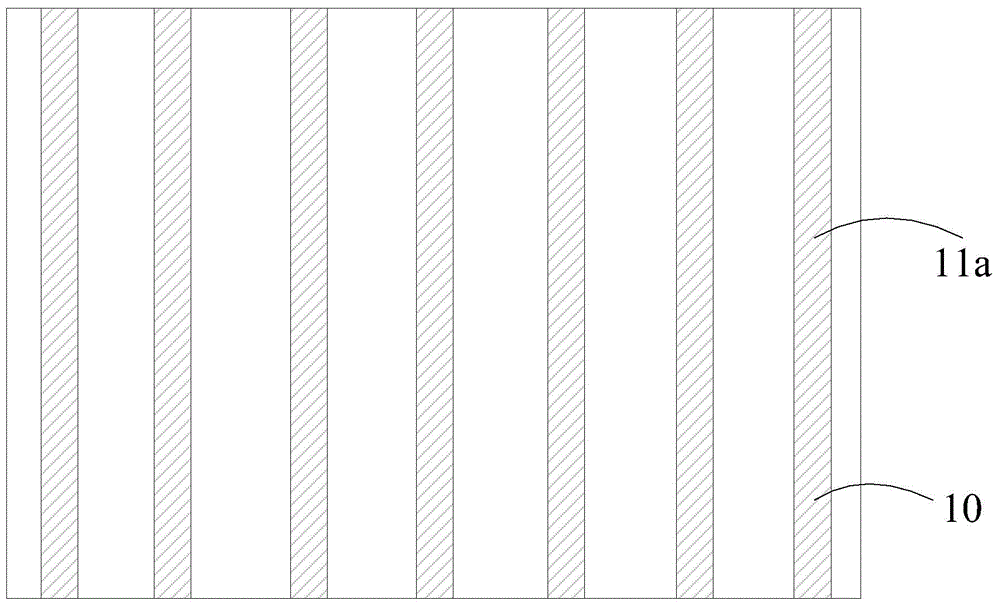

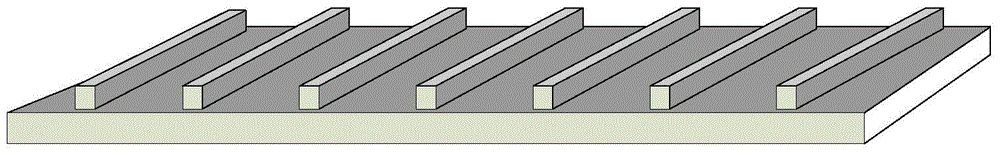

[0058] (1) Provide a transparent glass substrate and a mask plate, the mask plate is attached to the surface of the glass substrate; place the glass substrate on a 1×10 -5 In the vacuum coating chamber of Pa, the magnetron sputtering method is used to prepare 7 oxide layers arranged side by side and spaced apart on the side of the glass substrate attached with the mask plate. The material is titanium dioxide, and the sputtering speed is 0.5nm / s; The material layer is strip-shaped, with a thickness of 5 μm and a width of 5 μm, and the interval between two adjacent oxide layers is 5 μm;

[0059] (2) Remove the mask, and prepare a sulfide layer on the surface of the glass substrate and the surface of the oxide layer by vacuum hot-coating method. The material is zinc sulfide, and the evaporation speed is 0.2nm / s; the sulfide layer is a continuous film layer with a wavy surface st...

Embodiment 2

[0067] A method for preparing an organic electroluminescent device, comprising the following steps:

[0068] (1) Provide a transparent glass substrate and a mask plate, the mask plate is attached to the surface of the glass substrate; place the glass substrate on a 1×10 -3 In the vacuum coating chamber of Pa, the magnetron sputtering method is used to prepare 7 oxide layers arranged side by side and arranged at intervals on the side of the glass substrate attached with the mask plate. The material is silicon dioxide, and the sputtering speed is 5nm / s; The oxide layer is strip-shaped, with a thickness of 20 μm and a width of 20 μm, and the interval between two adjacent oxide layers is 20 μm;

[0069] (2) Remove the mask, and prepare a sulfide layer on the surface of the glass substrate and the surface of the oxide layer by vacuum hot-coating method. The material is zinc selenide, and the evaporation speed is 2nm / s; the sulfide layer is a continuous film A layer with a wavy sur...

Embodiment 3

[0075] A method for preparing an organic electroluminescent device, comprising the following steps:

[0076] (1) Provide a transparent glass substrate and a mask plate, the mask plate is attached to the surface of the glass substrate; place the glass substrate on a 1×10 -4 In the vacuum coating chamber of Pa, 7 oxide layers arranged side by side and arranged at intervals are prepared on the side of the glass substrate with the mask plate by magnetron sputtering method. The material is zirconium dioxide, and the sputtering speed is 2nm / s; The oxide layer is strip-shaped, with a thickness of 10 μm and a width of 10 μm, and the interval between two adjacent oxide layers is 10 μm;

[0077] (2) Remove the mask, and prepare a sulfide layer on the surface of the glass substrate and the surface of the oxide layer by vacuum hot-coating method. The material is zinc sulfide, and the evaporation speed is 1nm / s; the sulfide layer is a continuous film layer , with a wavy surface structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com