Reflection type light projector device

An optical device and reflective technology, applied in the direction of reflectors, lighting devices, and components of lighting devices, etc., can solve the problems of low improvement space, bulky lamps, and inability to emit reflected light, and achieve the effect of reducing the volume of lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

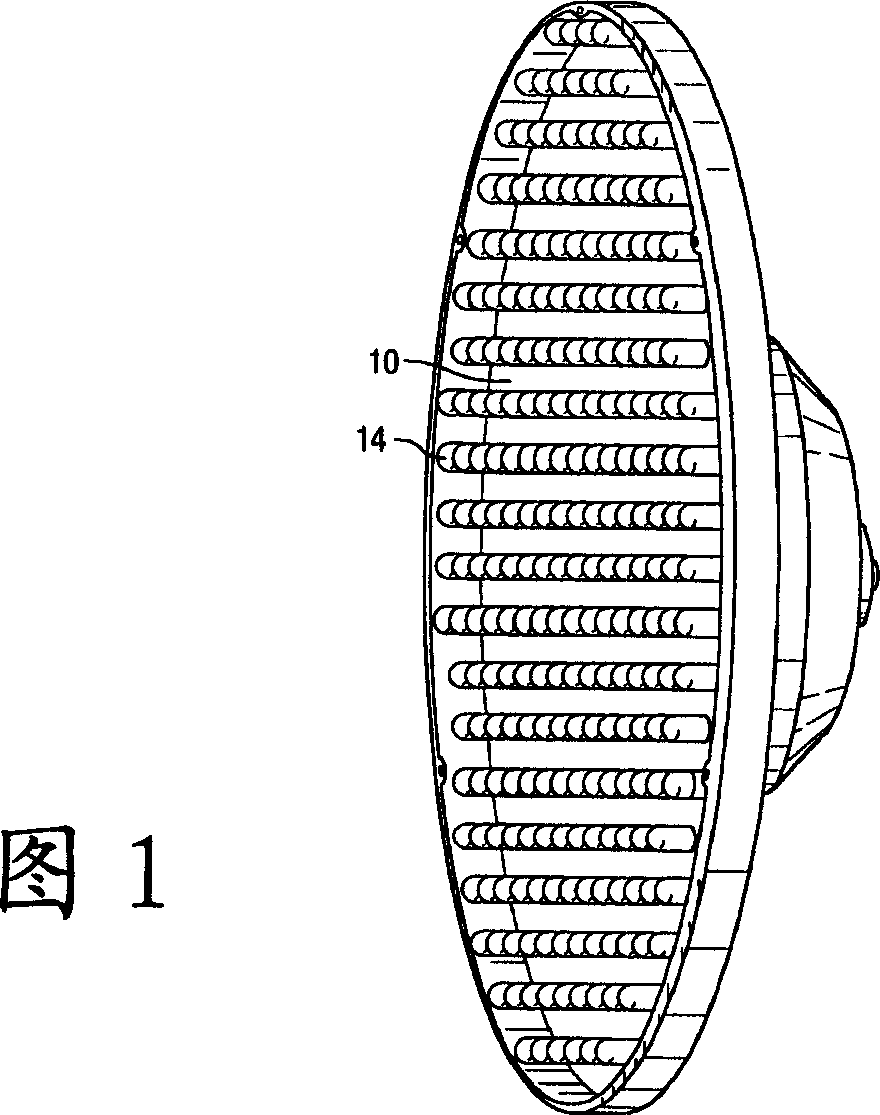

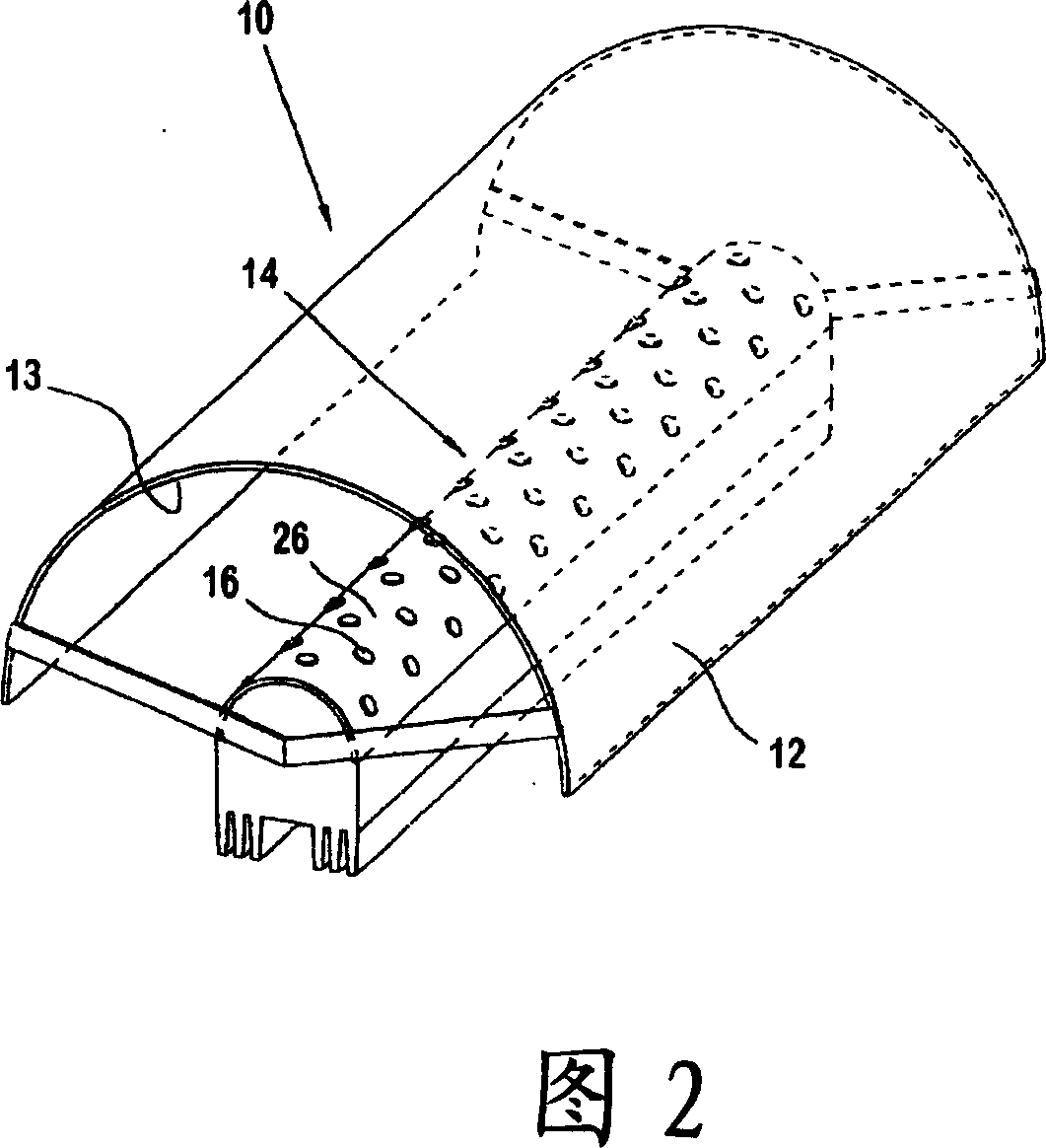

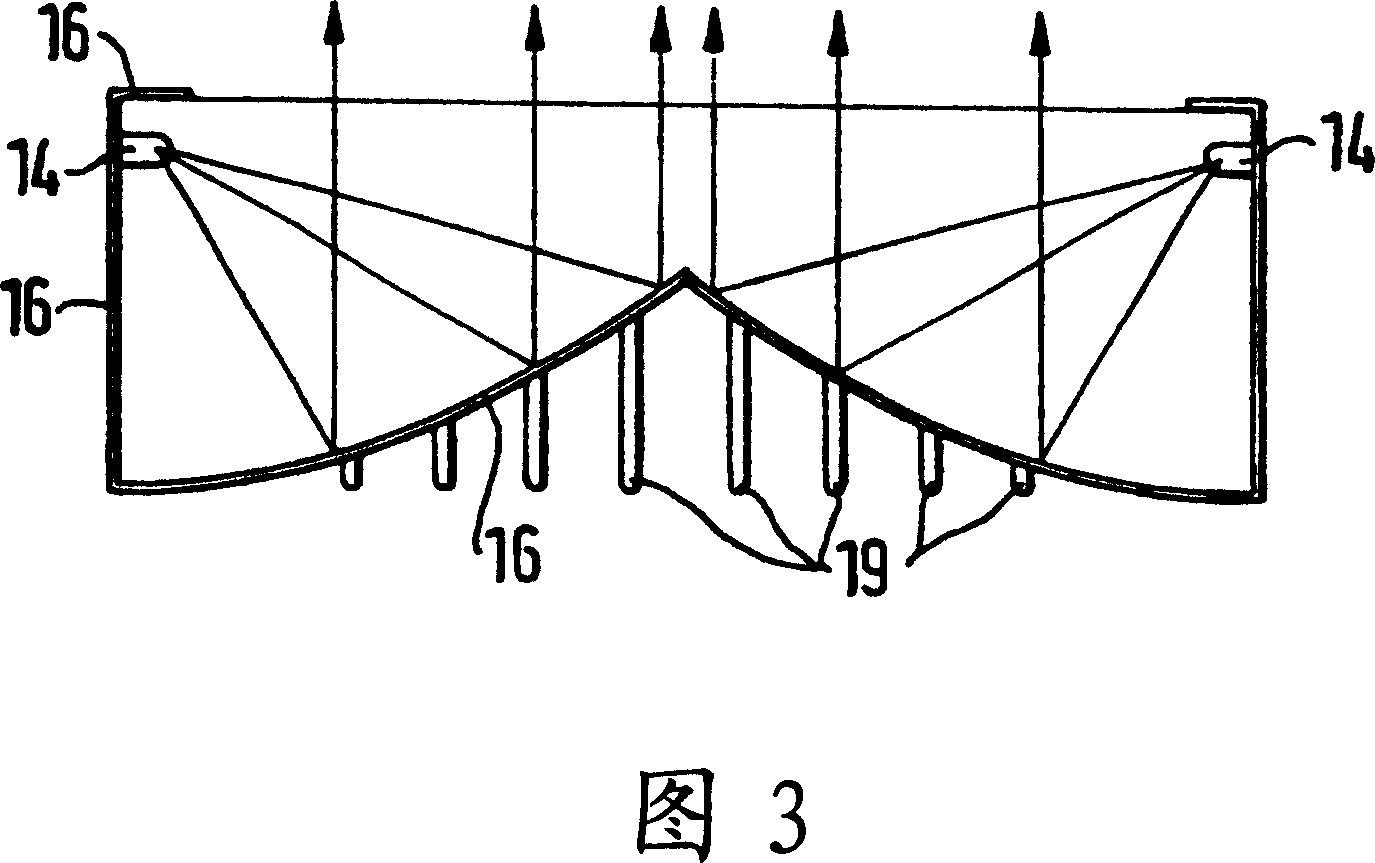

[0050] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the attached drawings.

[0051] Please refer to FIG. 5, a reflective light projection device provided by the present invention includes a light guide cover 10 and at least one light source 20. The light guide cover 10 is made of a material with reflective properties. The inner sidewall of the light guide cover 10 can be provided with a reflective layer (not shown) to improve the light reflectivity, the material of the reflective layer can be the existing reflective diffusion film used in flat panel displays, or can be made of Metal materials such as aluminum or electroless nickel are formed by electroplating. The light source 20 is preferably a directional light source with a certain light output angle, such as a light emitting diode. The light guide cover 10 has a bottom 11 and at least one light output port. 12. A feature of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com