Ultrasonic time-of-flight diffraction (TOFD) detection method for weld seam

A detection method, ultrasonic technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

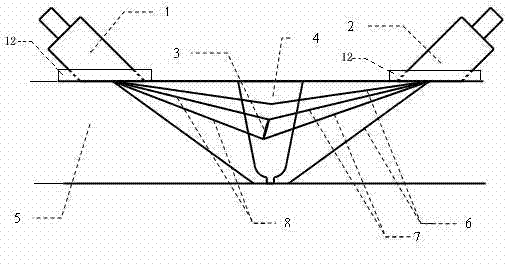

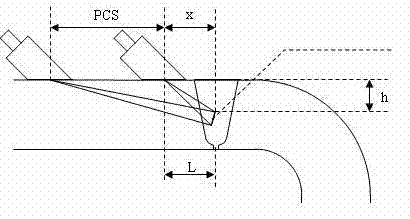

[0014] Such as figure 1 As shown, the probes of the conventional TOFD detection technology are placed on both sides of the weld, and it cannot detect the butt welds of pressure pipes and special-shaped components such as elbows, big and small heads or tees. Such as figure 2 Shown is a schematic diagram of the probe layout of the method of the present invention, the receiving probe 1 selects a probe with a large refraction angle (60 degrees), and the transmitting probe 2 selects a probe with a small refraction angle (20 degrees); in order to ensure that the ultrasonic waves can cover the weld seam to the greatest extent The region can obtain as high a signal-to-noise ratio as possible, and the distance L between the probe spacing PCS and the center line of the transmitting probe 2 and the weld 4 is determined according to the thickness of the workpiece and the angle of the probe; the above-mentioned two probes are installed on the scanning frame 12, and Connect with the TOFD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com