Ultrasonic detection method for weld joint of small-caliber pipe shelf angle

A detection method and ultrasonic technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of missed detection, false detection and influence of workpiece detection, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

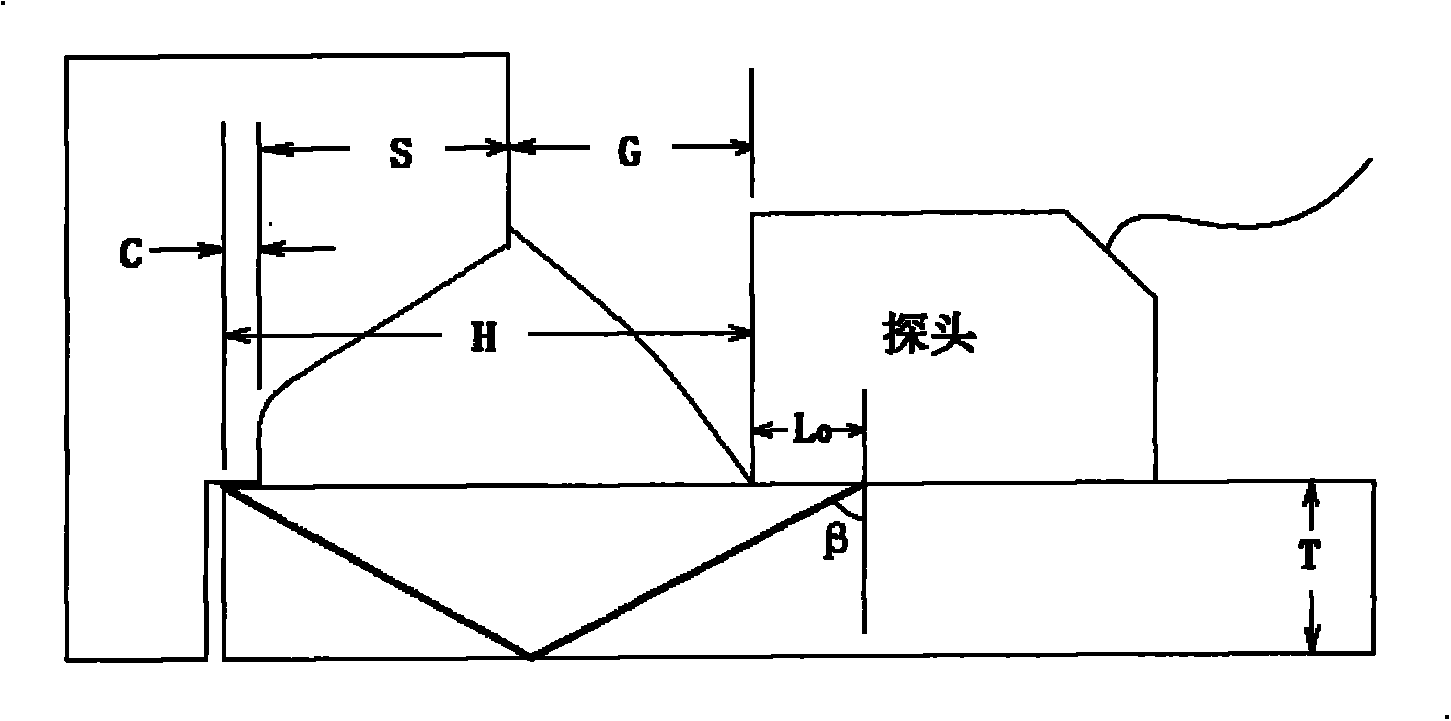

[0014] like figure 1 As shown in the figure, an ultrasonic testing method for fillet welds of small-diameter pipe bases, aiming at the fillet welds of pipe joints with a specification of Φ60×10mm, adopts a single crystal shear wave oblique probe with a corresponding refraction angle to detect from the outside of the pipe base, and the steps are as follows:

[0015] Step 1: According to β≥tan -1 [(H+L 0 ) / 2T] to calculate and determine the refraction angle of the probe. Through the actual measurement, the height of the fillet weld is G=14mm, the depth of the groove of the header is S=14mm, the insertion depth of the pipe joint is C=2mm, and the wall thickness of the pipe joint is T= 10mm, the probe used is a special probe for small diameter pipes, and the leading edge distance is L 0 =5mm,

[0016] Shell: H=G+S+C=14+14+2=30mm

[0017] β≥tan -1 [(H+L 0 ) / 2T]≥tan -1 [(30+5) / 20]≥60.3°

[0018] The probe can be prepared according to β=50°, 55°, 60°, 65°, 70°, and finally se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com