Pressure vessels top cover actuating device lower omega welding seam ultrasonic inspection method and device

A driving mechanism and pressure vessel technology, applied in the field of ultrasonic inspection, can solve problems such as narrow inspection space and inability to inspect, and achieve the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

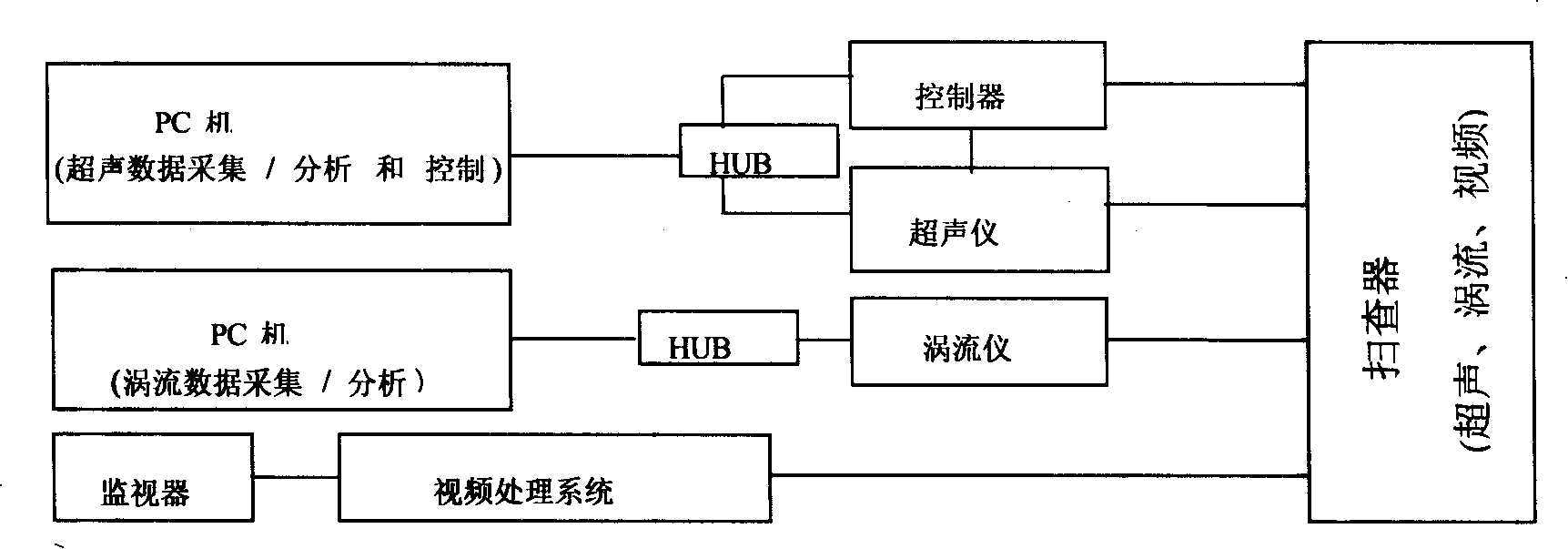

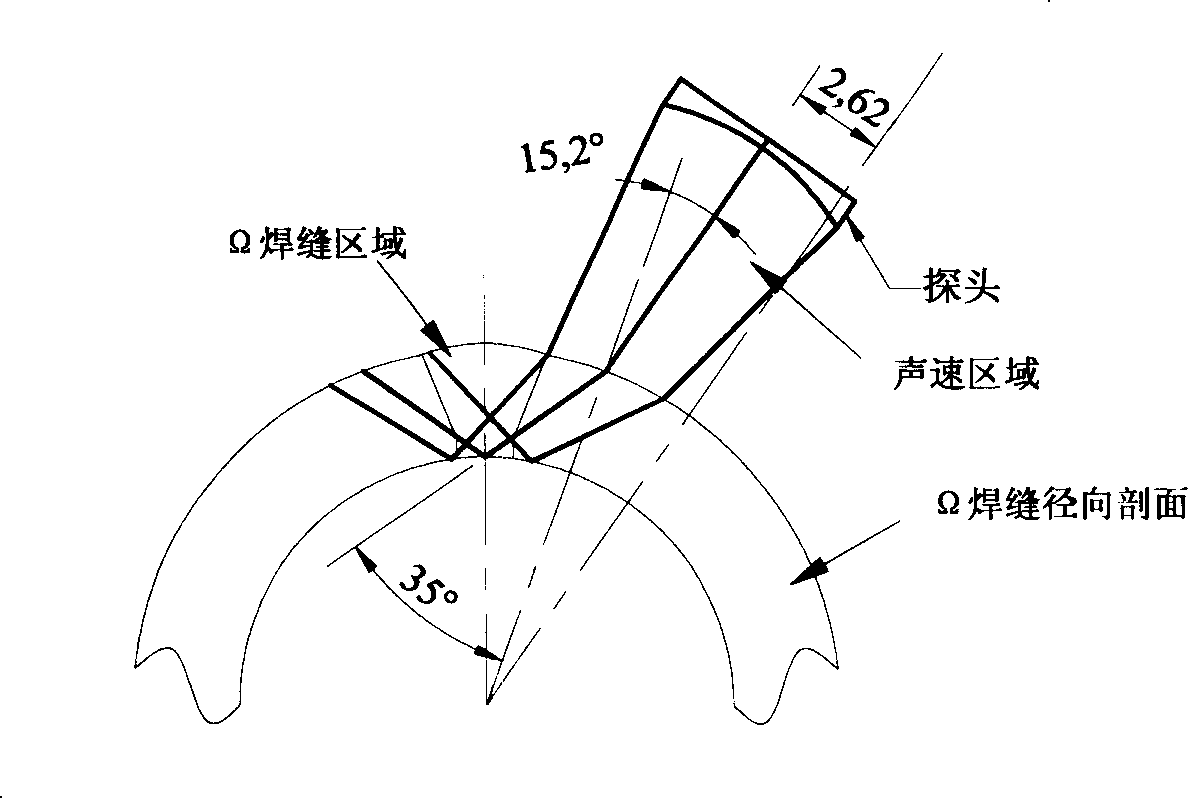

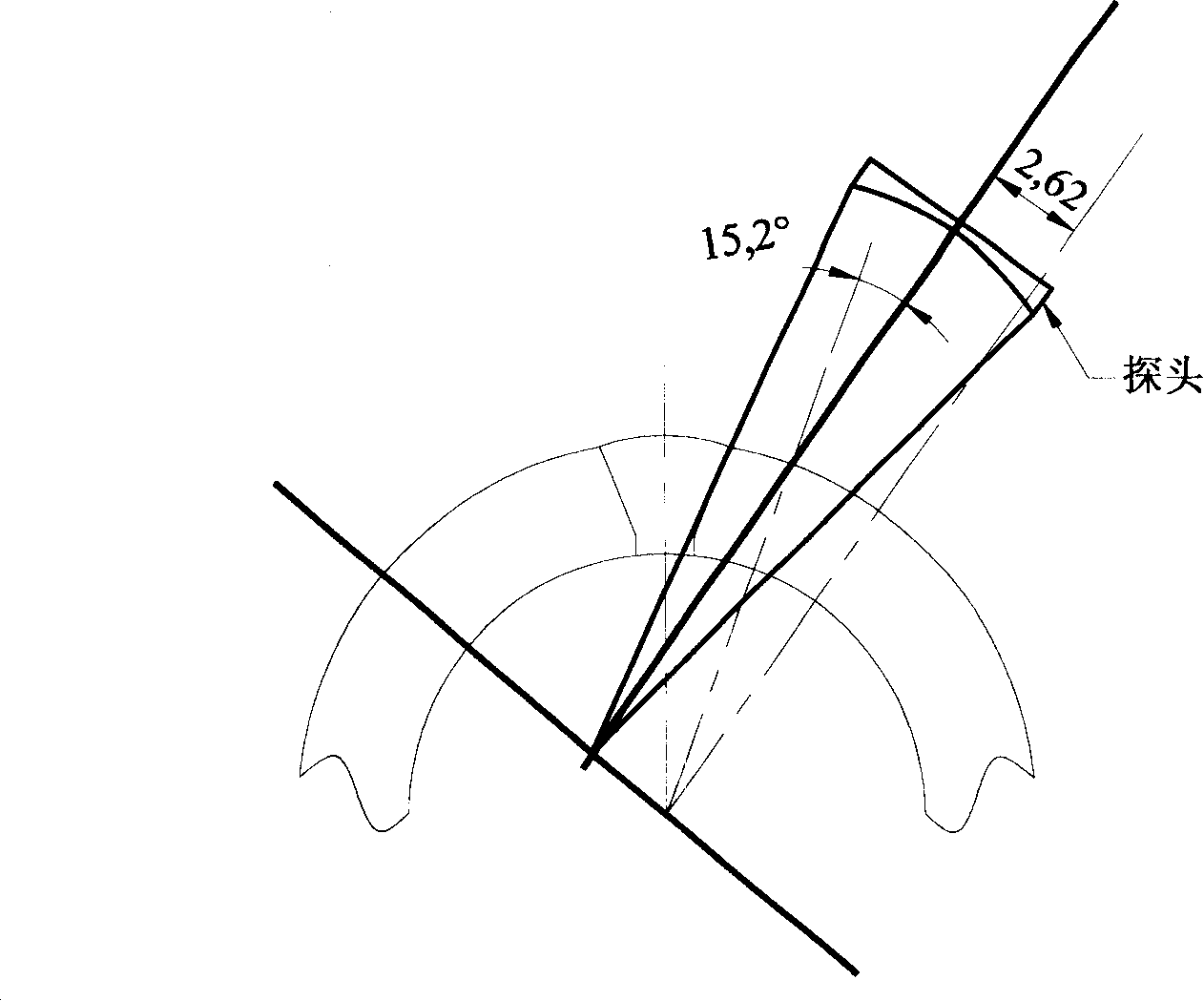

[0021] The ultrasonic inspection method for the Ω weld of the lower part of the drive mechanism of the pressure vessel top cover is to scan the Ω weld with an ultrasonic probe, use a digital ultrasonic instrument to collect the signal, and then analyze the signal through a PC. Among them, the scan of the weld At the same time, four ultrasonic probes are used for array scanning, and the scanning trajectory formed by four-point incidence is shown in Fig. Figure 4 , The four ultrasonic probes are all incident with the refraction angle of 35 degrees as the transverse wave, and the water immersion focus detection. Since the sound beam has a certain width, it can be seen from the figure that there will be no blind spots in the scanning area.

[0022] In order to ensure that the ultrasonic waves will not propagate and attenuate in the workpiece, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com