Manufacture method of low-attenuation white light LED

A production method and low-attenuation technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost, complex process, light attenuation and product reliability decline, and achieve low reflectivity, simple operation process, and light less attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

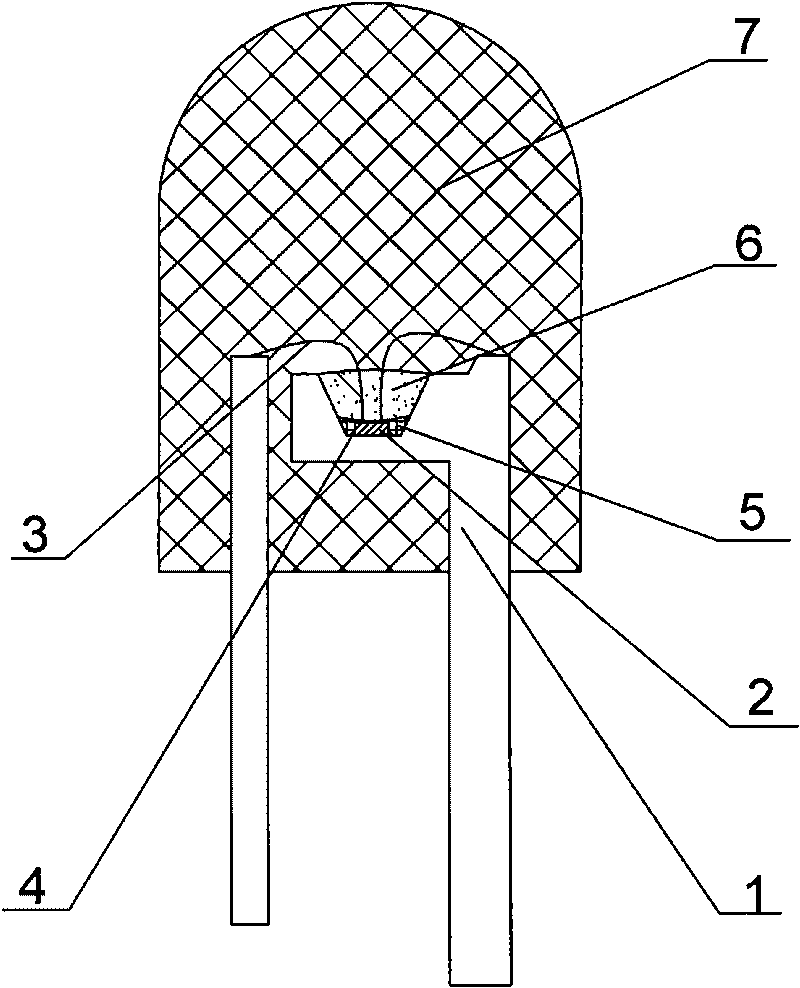

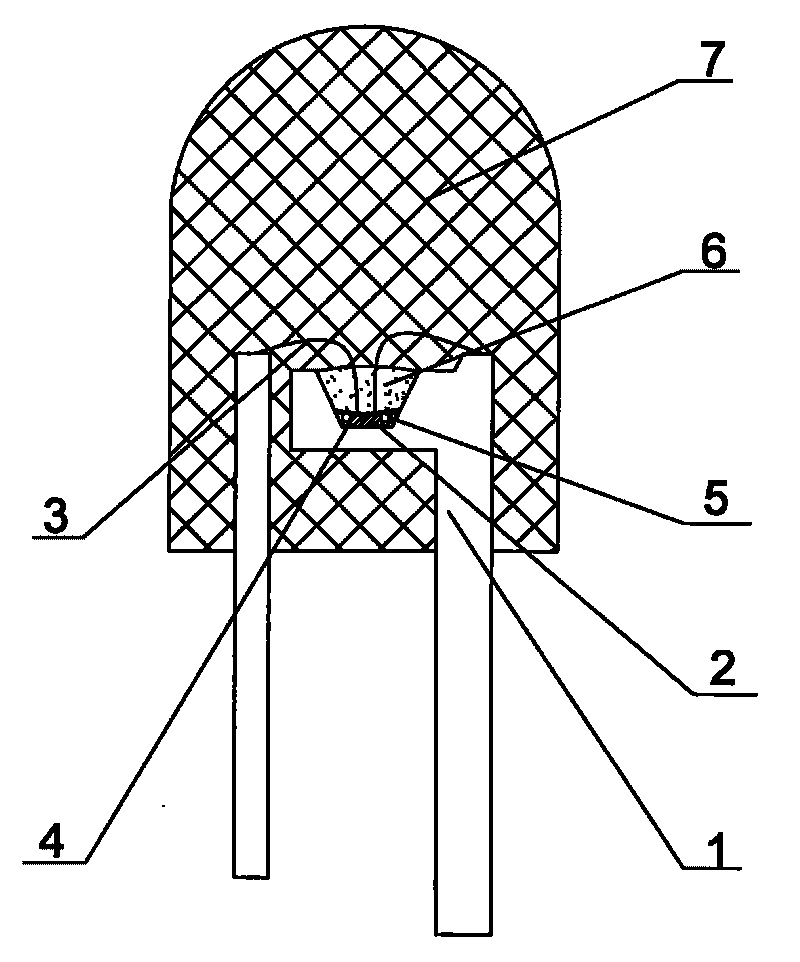

[0027] 1) Fix the blue chip 2 in the base of the bracket 1, and weld the gold wire 3;

[0028] 2) Add the oxides of Ca, Mg, Ti, Si, Zr, Gd elements to the main agent of silica gel, the weight of the oxide accounts for 1% of the weight of the main agent of silica gel, and the particle size is 3-10um, and stir evenly;

[0029] 3) Mix the stirred silicone main agent with the curing agent and stir evenly;

[0030] 4) Add yellow fluorescent powder to the silica gel containing two components of silica gel main agent and curing agent, the weight of the yellow fluorescent powder accounts for 5% of the weight of the silica gel, and stir evenly;

[0031] 5) Coating the stirred silica gel mixture on the blue chip 2 to form the first coating layer 5, the first coating layer 5 should completely encapsulate the blue chip 2;

[0032] 6) Baking and curing the first coating layer 5, the baking temperature is 120°C-150°C, and the baking time is 1-2 hours;

[0033] 7) Add the oxides of Ca, Mg,...

Embodiment 2

[0037] The production method of this embodiment is basically the same as that of Embodiment 1, the difference is that in steps 2), 4), and 7), the weight percentages of oxide and yellow phosphor are respectively 3%, 7%, and 4%, and then Make adjustments.

Embodiment 3

[0039] The production method of this embodiment is basically the same as that of Embodiment 1, the difference is that in steps 2), 4), and 7), the weight percentages of oxide and yellow phosphor are respectively 5%, 10%, and 5%, and then Make adjustments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com