Ultrasonic testing method for bonding quality of coated steel sheet and rubber

A technology of coated steel plate and detection method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., and can solve the problems of steel plate rubber bonding quality detection that cannot be coated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

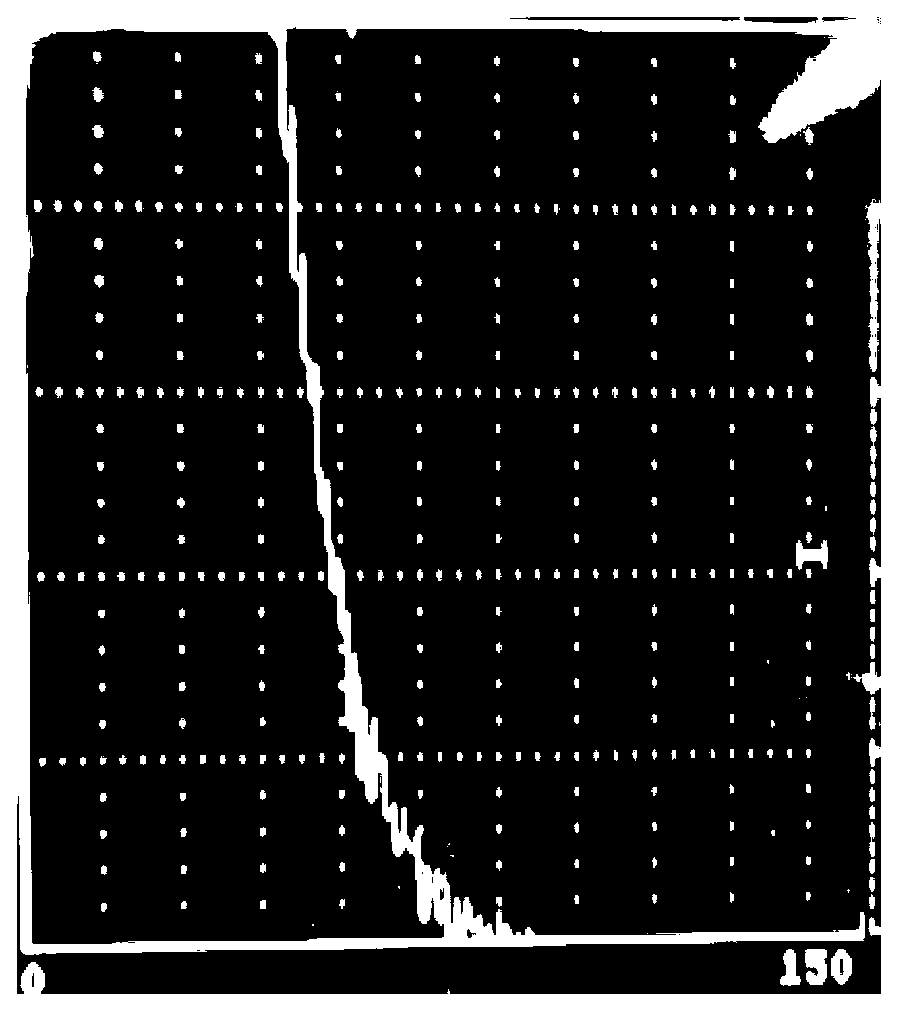

[0043] In this embodiment, the steel plate material to be tested is 30GrMnSiA, and the ultrasonic testing surface is sprayed with 0.4mm epoxy resin coating.

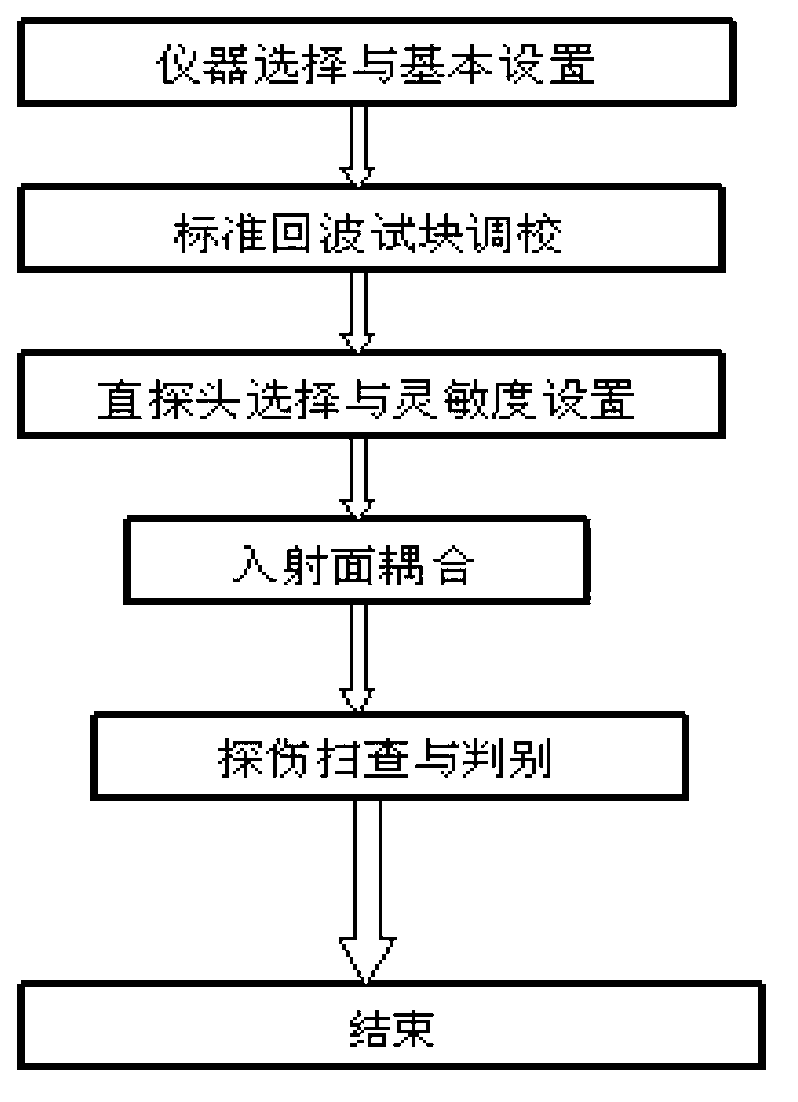

[0044] The specific process is:

[0045] Step 1: Ultrasonic detector selection and setting

[0046] The A-type pulse reflection ultrasonic detector is selected. In this embodiment, the CTS-23 pulse reflection ultrasonic detector commonly used in the industry is selected in order to generate pulsed ultrasonic waves and display real-time echo signals.

[0047] In order to make the ultrasonic detector display multiple echoes horizontally during the scanning process, the parameters of the pulse reflection ultrasonic detector are:

[0048] Detection mode: full wave; working mode: single probe spontaneous self-reception;

[0049] Suppression: Off; Scan Depth: 150mm.

[0050] Transmit intensity: minimum; frequency band selection: medium; repetition rate: X 1 ;

[0051] Step 2: Calibration of standard echo test block

[00...

Embodiment 2

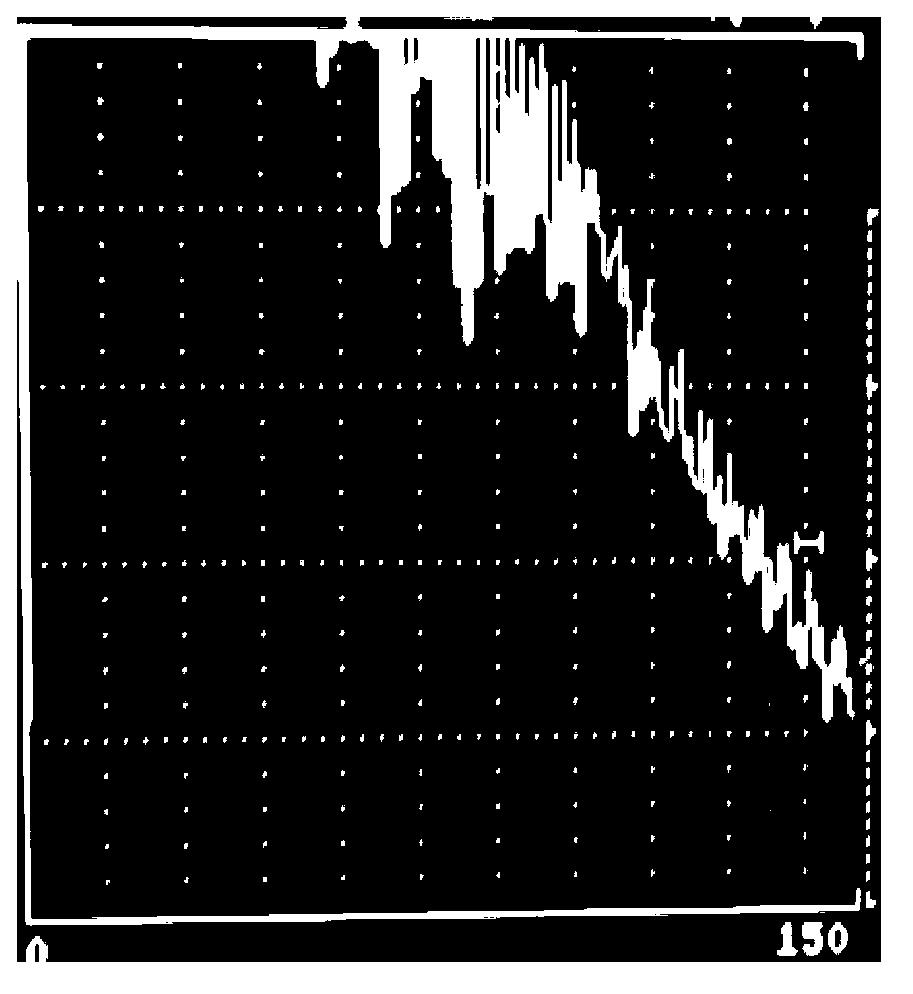

[0062] In this embodiment, the detected steel plate is D406A, and the ultrasonic detection surface is sprayed with 1.7mm epoxy resin coating.

[0063] The specific process is:

[0064] Step 1: Ultrasonic detector selection and setting

[0065] The A-type pulse reflection ultrasonic detector is selected. In this embodiment, the CTS-23 pulse reflection ultrasonic detector commonly used in the industry is selected in order to generate pulsed ultrasonic waves and display real-time echo signals.

[0066] In order to make the ultrasonic detector display multiple echoes horizontally during the scanning process, the parameters of the pulse reflection ultrasonic detector are:

[0067] Detection mode: full wave; working mode: single probe spontaneous self-reception;

[0068] Suppression: Off; Scan Depth: 100mm.

[0069] Transmit intensity: minimum; frequency band selection: medium; repetition rate: X 1 ;

[0070] Step 2: Calibration of standard echo test block

[0071] After the s...

Embodiment 3

[0081] In this embodiment, the steel plate material to be tested is 30GrMnSiA, and the ultrasonic testing surface is sprayed with 1.0mm epoxy resin coating.

[0082] The specific process is:

[0083] Step 1: Ultrasonic detector selection and setting

[0084] The A-type pulse reflection ultrasonic detector is selected. In this embodiment, the CTS-23 pulse reflection ultrasonic detector commonly used in the industry is selected in order to generate pulsed ultrasonic waves and display real-time echo signals.

[0085] In order to make the ultrasonic detector display multiple echoes horizontally during the scanning process, the parameters of the pulse reflection ultrasonic detector are:

[0086] Detection mode: full wave; working mode: single probe spontaneous self-reception;

[0087] Suppression: Off; Scan Depth: 150mm.

[0088] Transmit intensity: minimum; frequency band selection: medium; repetition rate: X 1 ;

[0089] Step 2: Calibration of standard echo test block

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com