Robot for overhauling primary side of steam generator of nuclear power plant

A steam generator and robot technology, applied in the field of robots, can solve the problems of control system controllability and stability reduction, high price, low cost performance, etc., and achieve the effect of improving maintenance efficiency, light weight, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in more detail below in conjunction with accompanying drawing example:

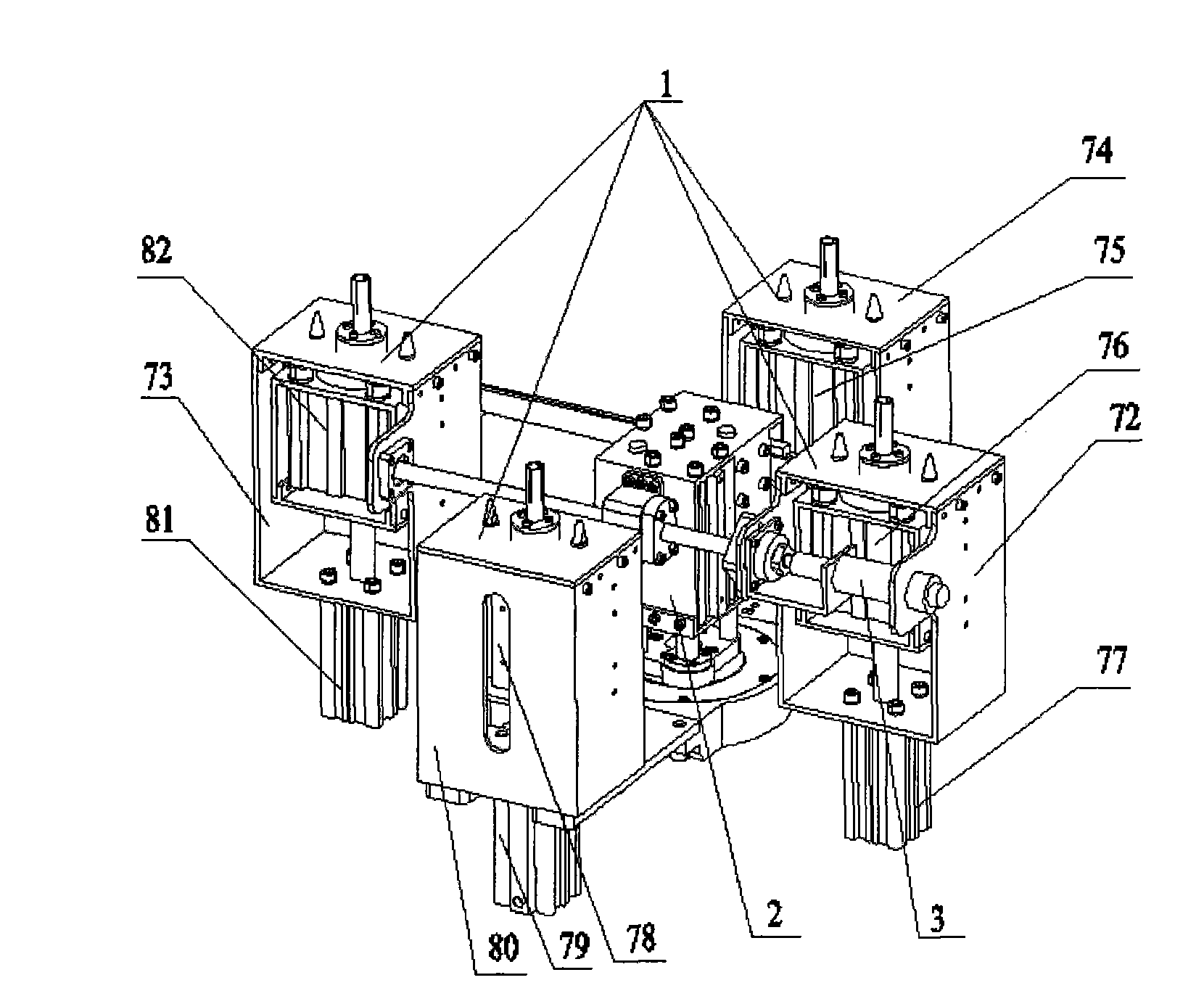

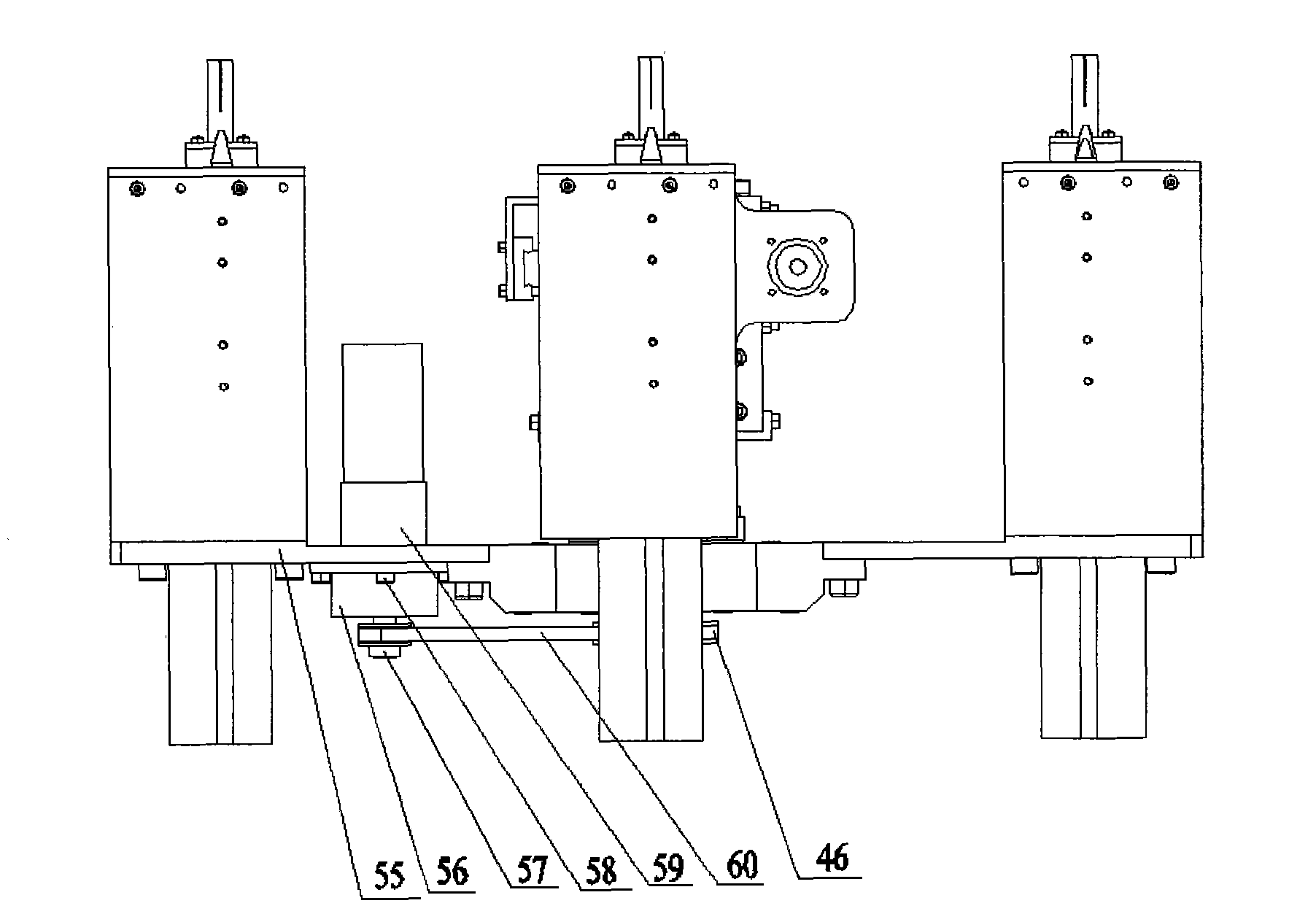

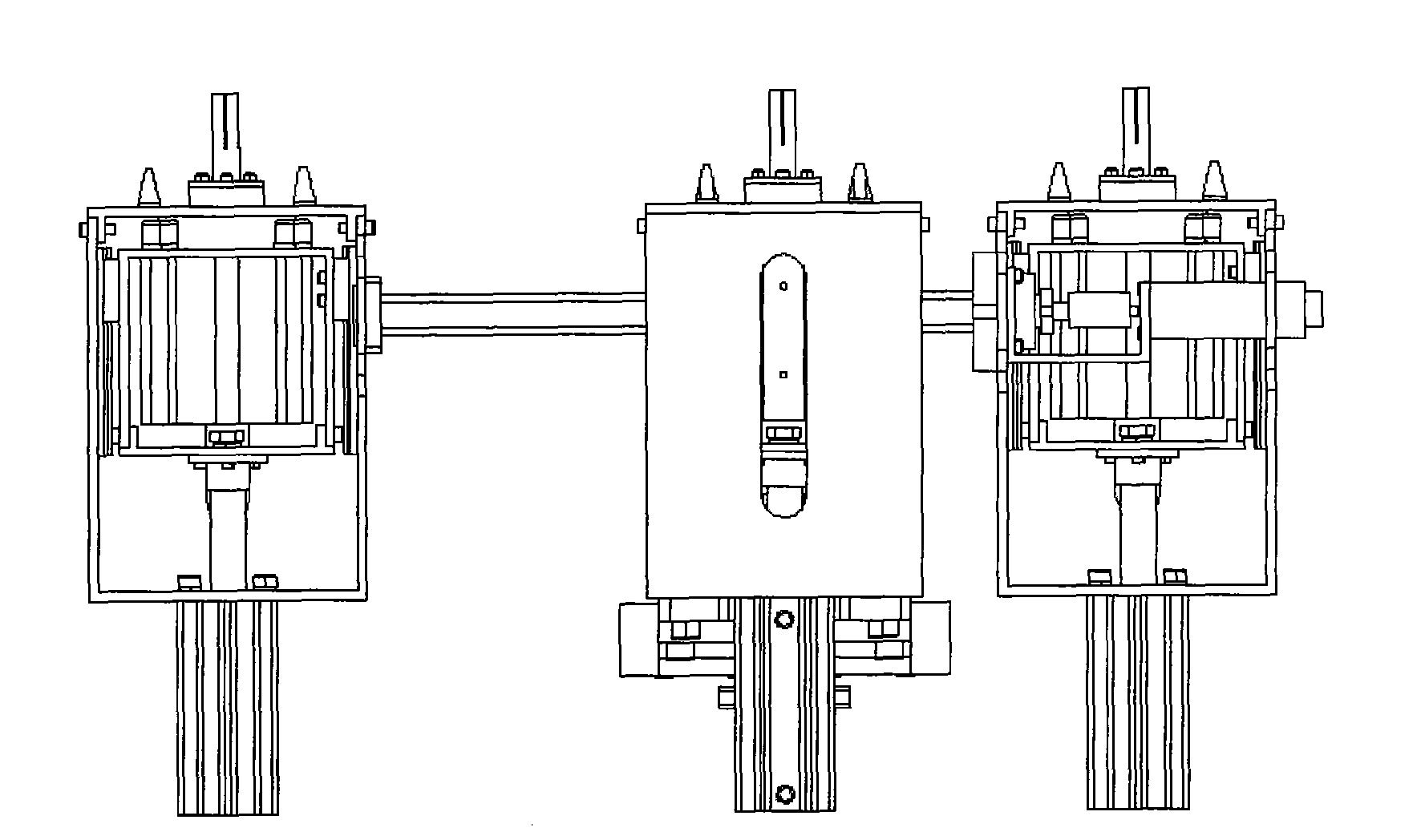

[0028] The robot designed by the present invention is mainly composed of 3 parts: a base unit 1, a rotating unit 2 and a sliding unit 3, such as figure 1shown. The base unit can be divided into two pairs of four modular units with basically the same structure. There are two cylinders in each module, which can produce two lifting movements with different functions. One pair of modular units can also be used for The detection equipment provides a carrying space, and the detection equipment can be easily replaced at any time according to different operation requirements. When working, a pair of pneumatic self-locking expansion mechanisms of the modular unit are required to extend into the heat transfer tube and expand tightly to form a gap with the inner wall. The static friction force will be used to support the total weight of the robot. The rotary unit is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com