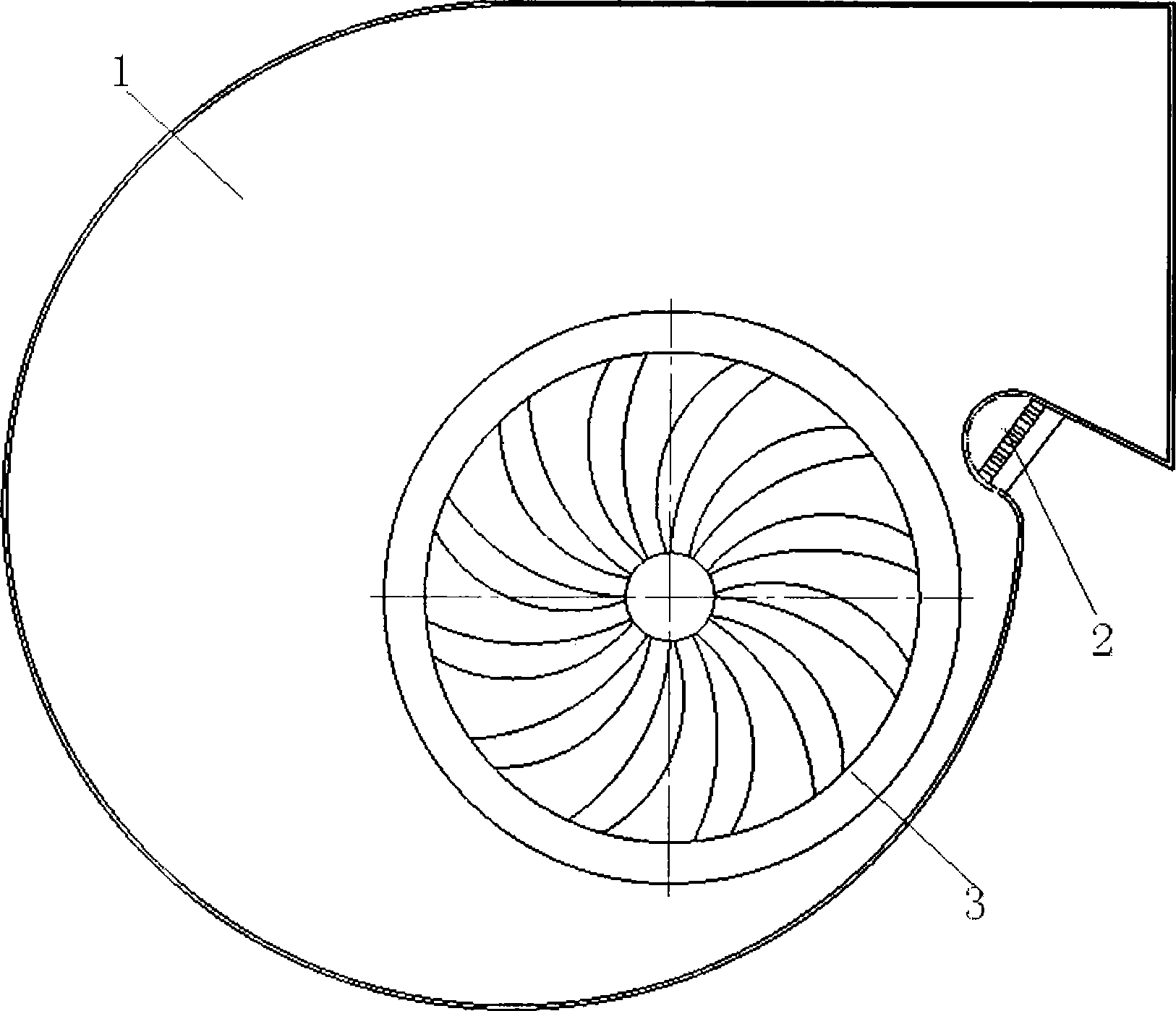

Bionic coupling noise elimination noise reduction spiral tougue

A volute tongue and noise reduction technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problems of complex processing, complex structure, and inconvenient wide application. Achieve the effect of simple processing and reduce eddy current shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

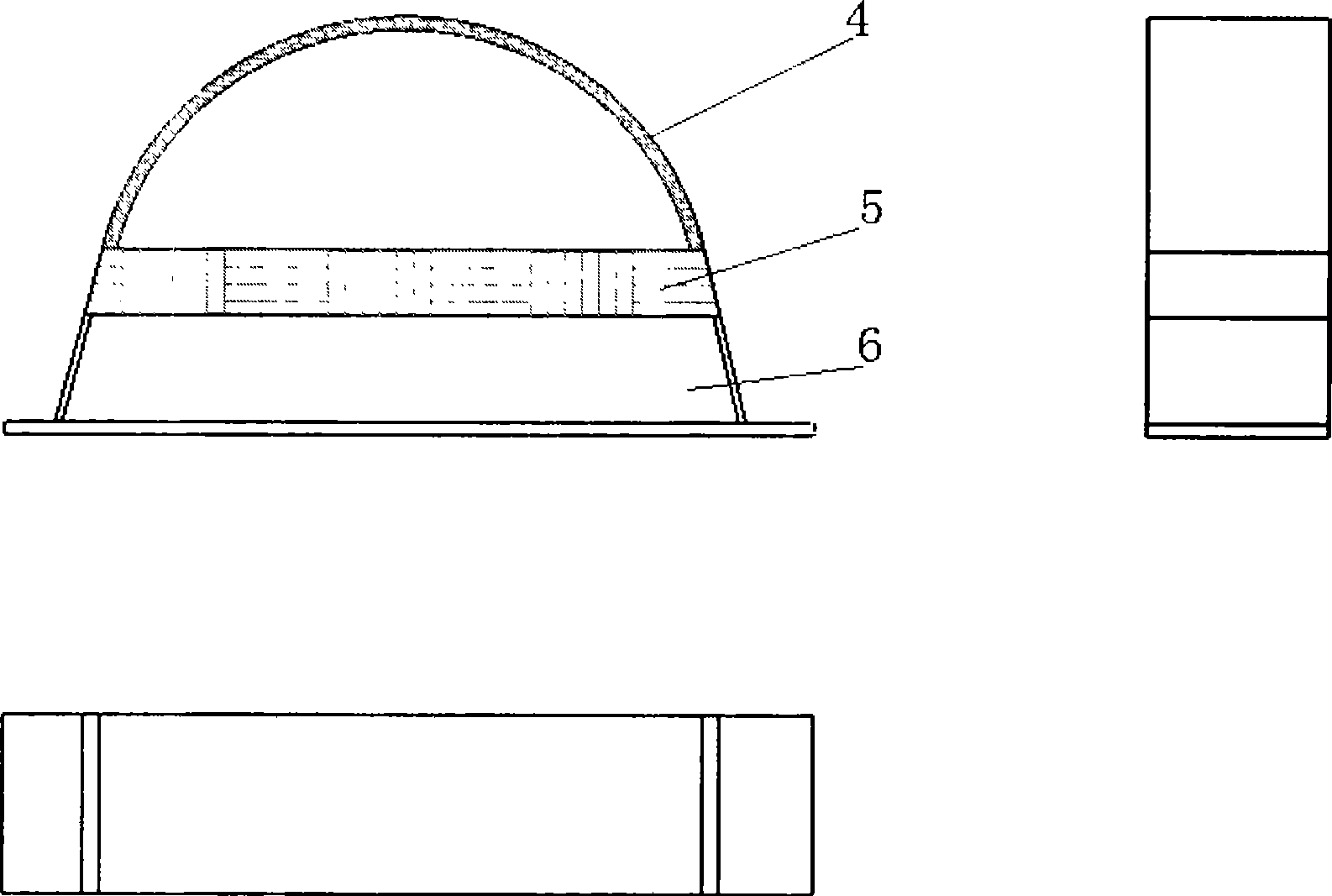

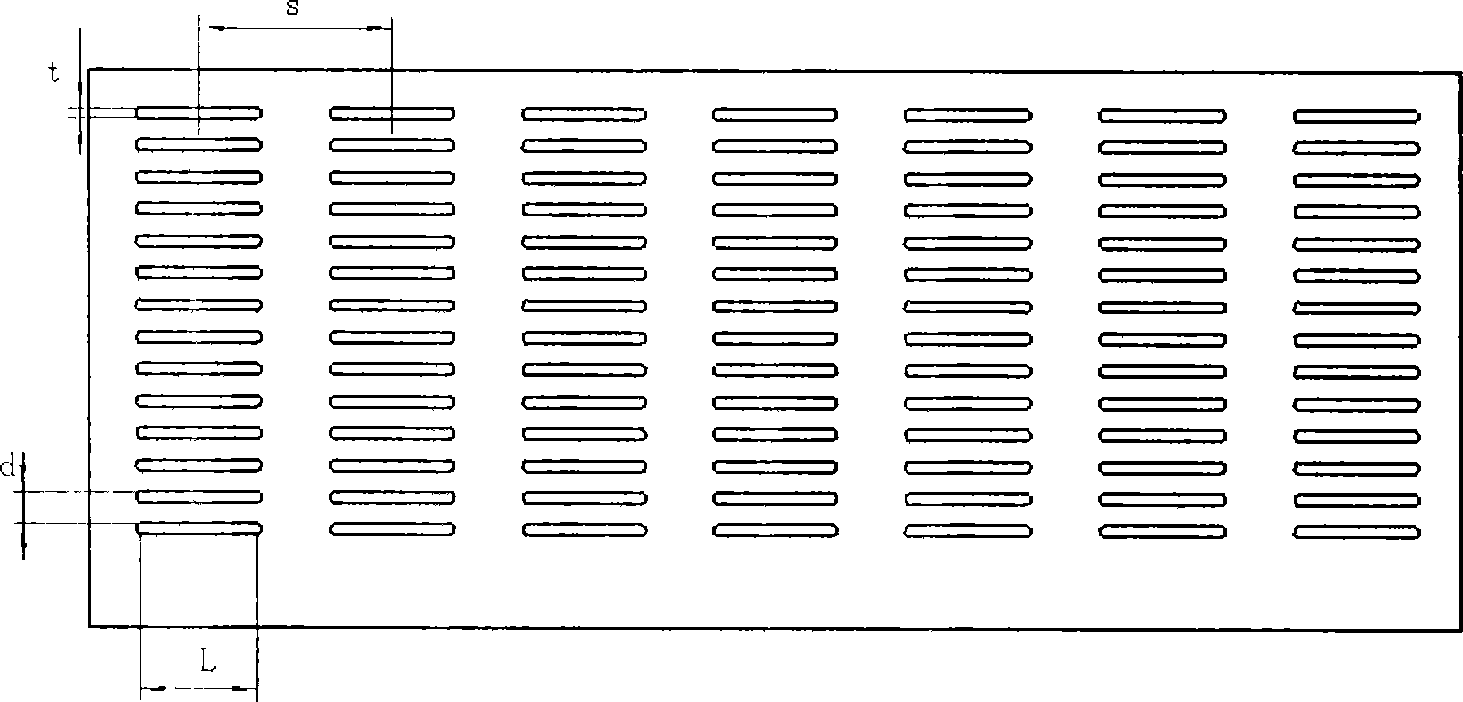

[0036]First measure the size of the fan volute tongue, determine the installation position of the bionic coupling noise reduction and noise reduction volute tongue, and then process the bionic coupling noise reduction volute tongue micro-slit plate layer 4 according to the measured size of the fan volute tongue, and the bionic coupling noise reduction volute tongue The thickness of the tongue micro-slit layer 4 is 1mm, the width of the micro-slit is 0.5mm, the center distance of the micro-slit is 4mm, and the opening rate is 3%. The vertical distance from the top of the curved surface of the micro-slit plate layer 4 to the micro-perforated plate layer 5 of the bionic coupling sound-absorbing volute tongue is the radius of the micro-slit plate layer 4 of the bionic coupling sound-absorbing volute tongue, and the length of the micro-perforated plate layer 5 of the bionic coupling sound-absorbing volute tongue is The diameter of the micro-slit plate layer 4 of the bionic coupling ...

Embodiment 2

[0038] First measure the size of the fan volute tongue, determine the installation position of the bionic coupling noise reduction and noise reduction volute tongue, and then process the bionic coupling noise reduction volute tongue micro-slit plate layer 4 according to the measured size of the fan volute tongue, and the bionic coupling noise reduction volute tongue The thickness of the tongue micro-slit layer 4 is 2mm, the width of the micro-slit is 0.5mm, the center distance of the micro-slit is 6mm, and the opening rate is 5%. The vertical distance from the top of the curved surface of the micro-slit plate layer 4 to the micro-perforated plate layer 5 of the bionic coupling sound-absorbing volute tongue is the radius of the micro-slit plate layer 4 of the bionic coupling sound-absorbing volute tongue, and the length of the micro-perforated plate layer 5 of the bionic coupling sound-absorbing volute tongue is The diameter of the micro-slit plate layer 4 of the bionic coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com