Enzyme catalysis electricity-conducting immunity sensor based on micro-gap array electrode and its immunity detecting method

An immunosensor and array electrode technology, which is applied in the field of enzyme-catalyzed conductance immunosensor and immunodetection based on micro-gap array electrodes, can solve the problem of low sensitivity, and achieve the effects of high sensitivity, portable price, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

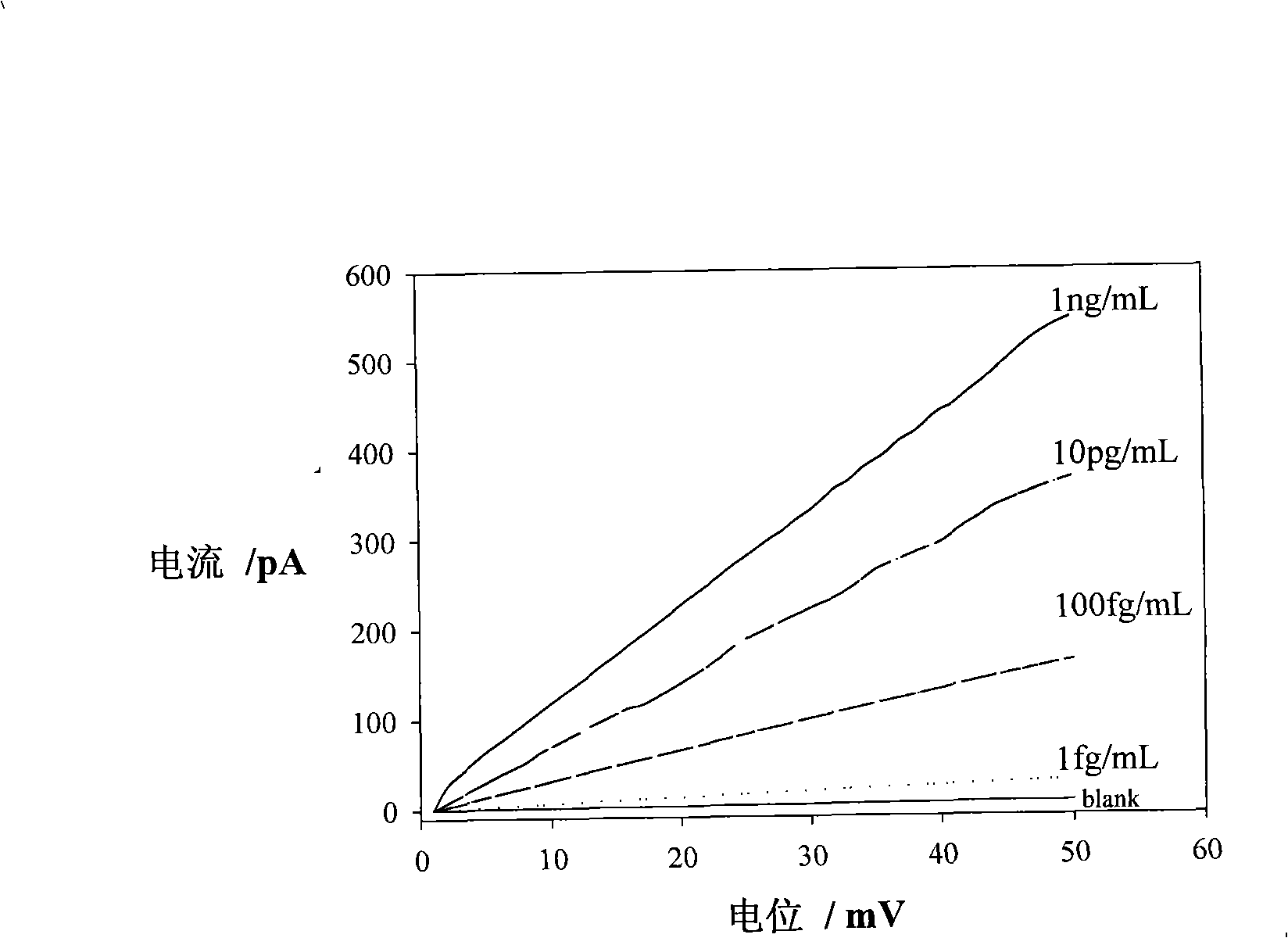

[0034] Example 1: Detection of human immunoglobulin G (hIgG) by an immunosensor based on micro-gap array electrodes.

[0035] 1. Preparation of immunosensor:

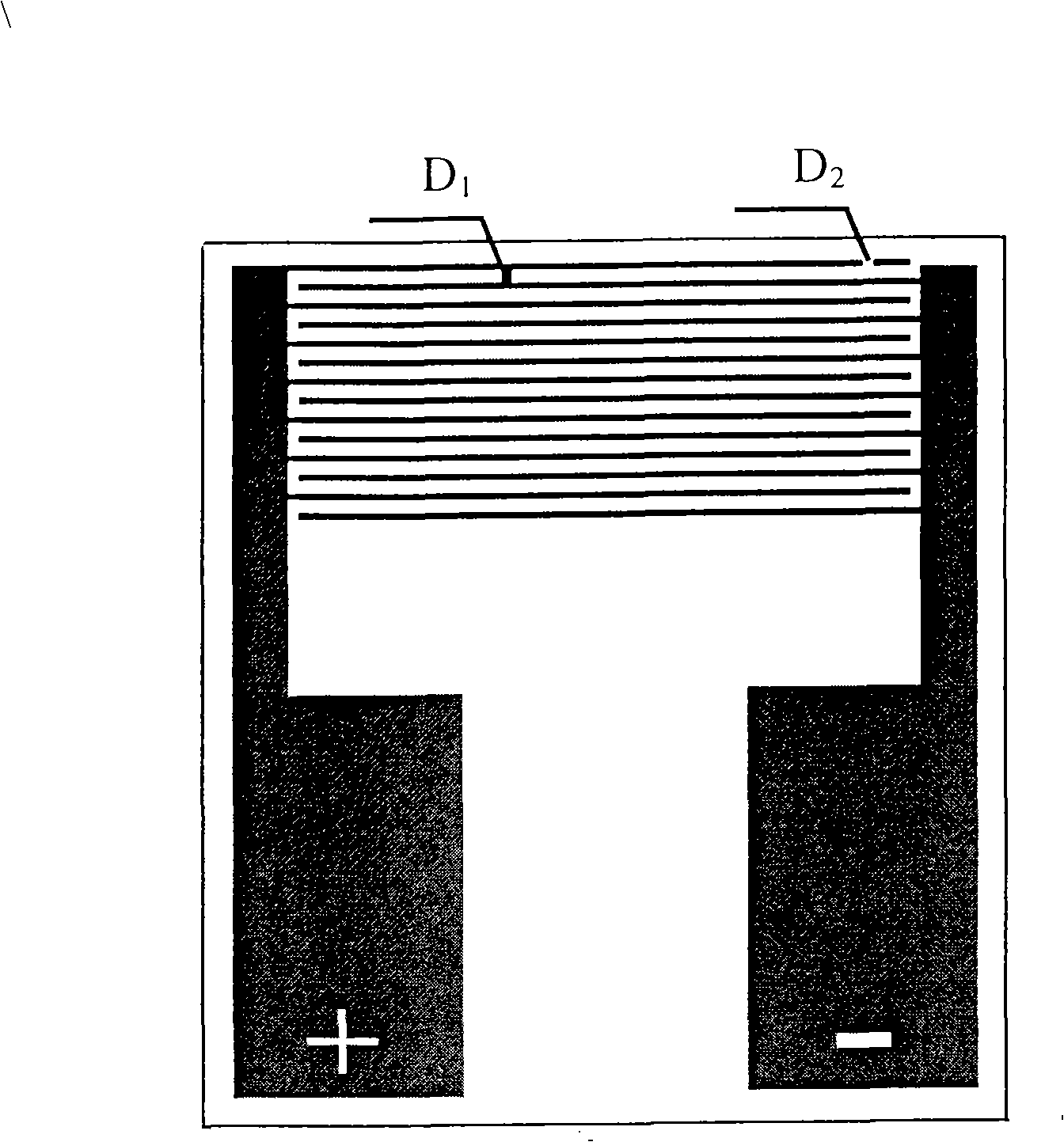

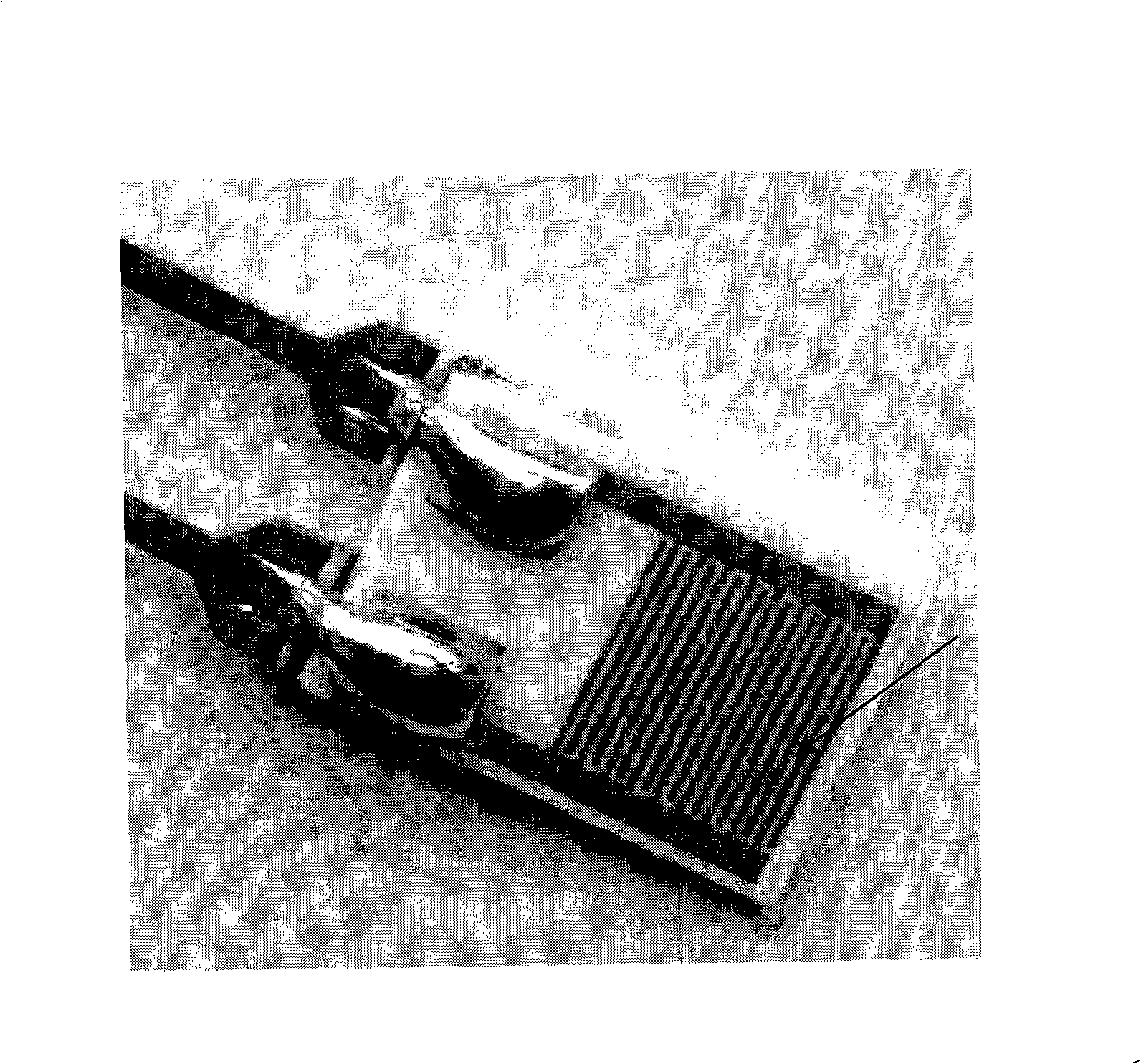

[0036] The micro-gap array gold electrode produced by the conventional photolithography printing method is used as the substrate, which is an interdigitated double electrode, and the positive and negative electrodes are two comb-shaped gold electrodes, which cross each other to form a micro-gap array gold electrode. Comb tooth width is 1μm-100μm, gap is 1μm-100μm;

[0037] After washing the microgap array gold electrode with absolute ethanol (100%) three times (1 min each time), the electrode was immersed in 1 M NaOH solution for 30 min; then the electrode was washed three times with ultrapure water (1 min each time), and dried . Then, the electrode was immersed in an ethanol solution containing 5% (volume percentage) of aminopropyltrimethoxysilane, and stood at room temperature for 24 hours. After washing with ultra...

Embodiment 2

[0042] Example 2: Detection of prostate-specific antigen (PSA) by an immunosensor based on micro-gap array electrodes.

[0043] 1. Preparation of immunosensor:

[0044] After washing the microgap array gold electrode with absolute ethanol (100%) three times (1 min each time), the electrode was immersed in 1 M NaOH solution for 30 min; then the electrode was washed three times with ultrapure water (1 min each time), and dried ; Then, immerse the electrode in an ethanol solution containing 5% (volume percent) of aminopropyltrimethoxysilane, and let it stand at room temperature for 24 hours. After washing with ultrapure water for three times and drying, a silanized micro-gap array gold electrode was obtained.

[0045] Immerse the silanized micro-gap array gold electrode in glutaraldehyde aqueous solution (5% mass fraction), and let it stand at room temperature for 1 hour; after washing with ultrapure water three times, add 30 μL mouse anti-human PSA monoclonal antibody solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com