Preparation method of QAS polymer anion exchange membrane

An anion-exchange membrane and polymer technology, applied in the field of ion-exchange membranes, can solve the problems of anion-exchange membrane performance degradation, strong volatility, and environmental pollution, achieve good mechanical properties and chemical stability, and avoid hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

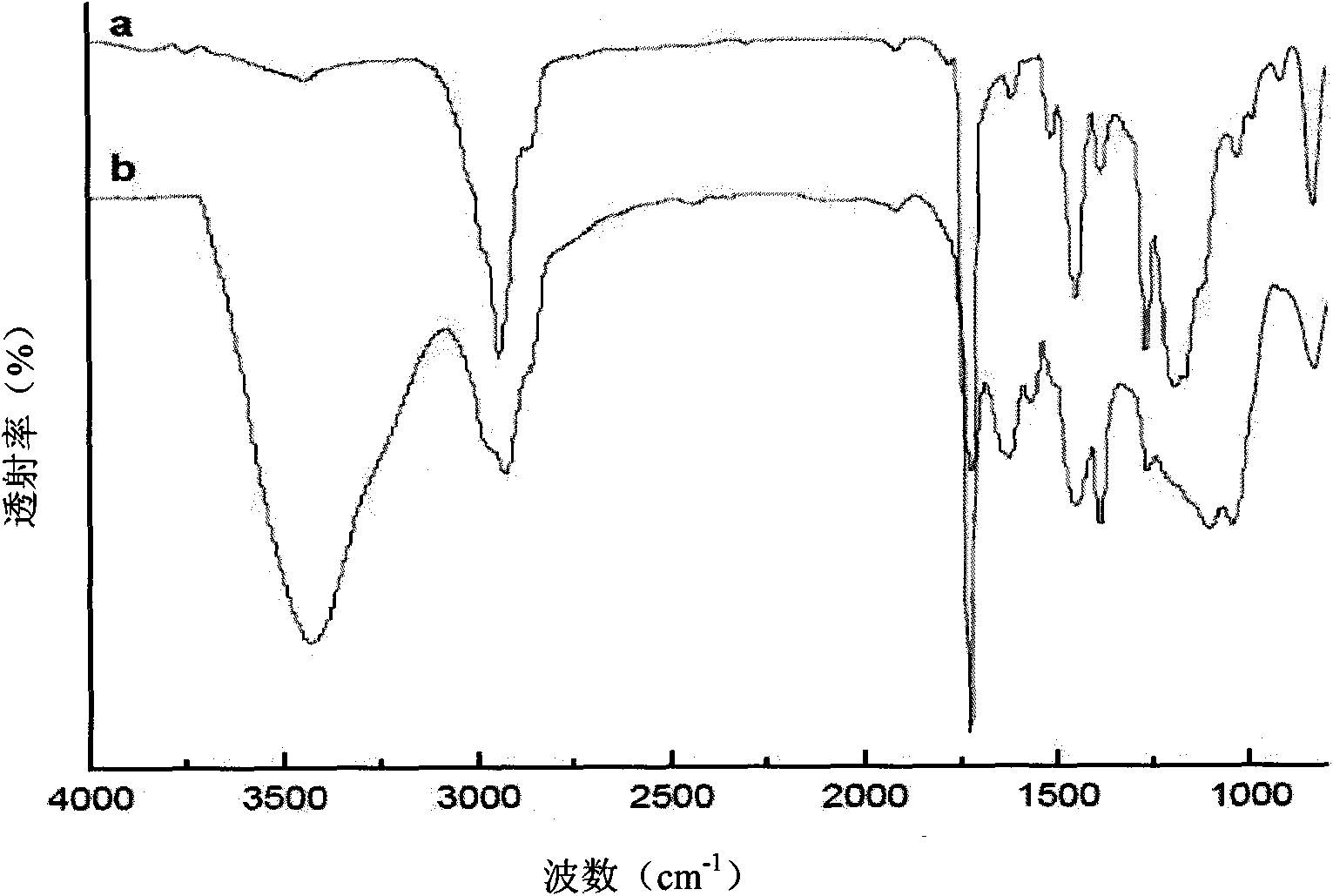

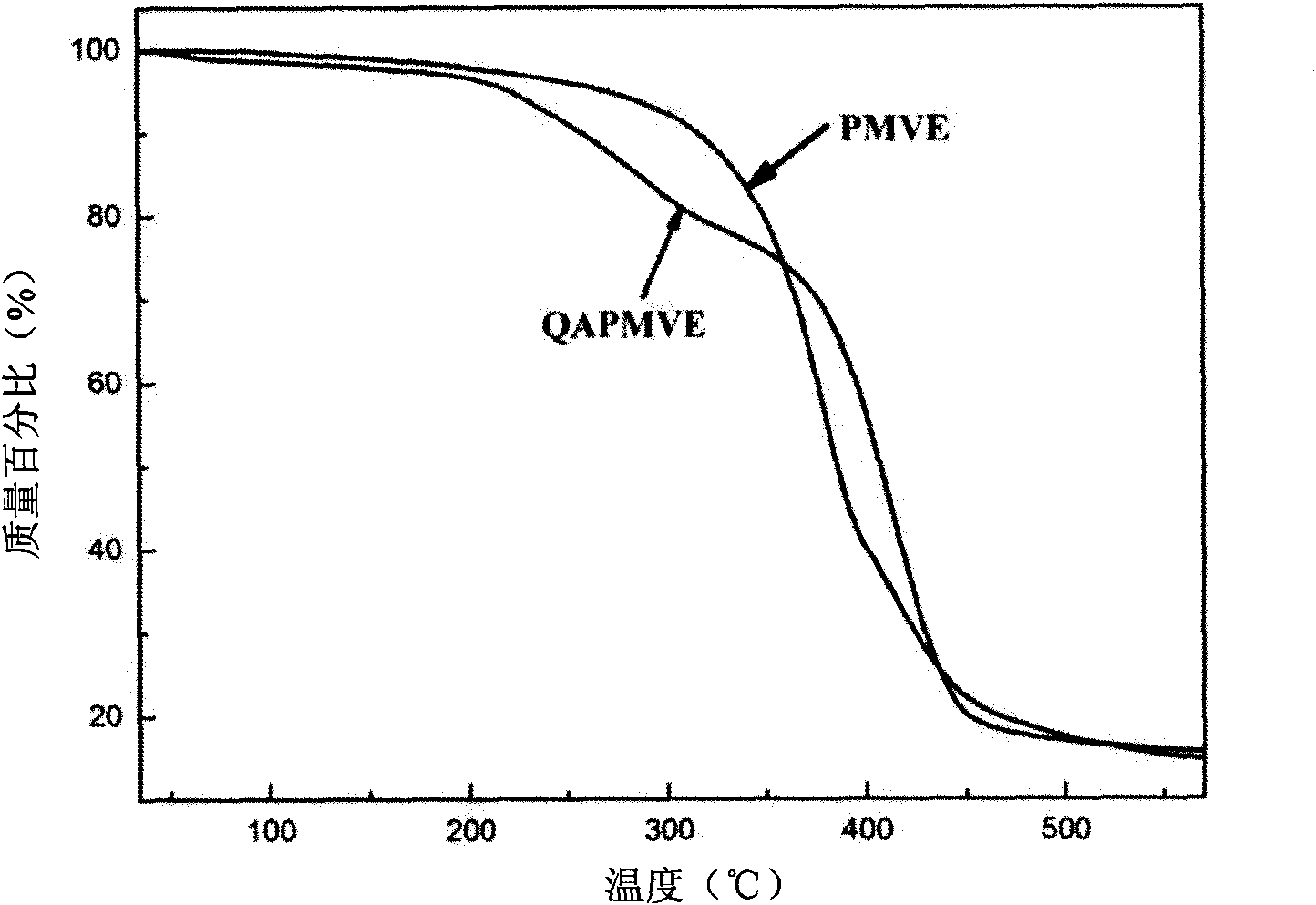

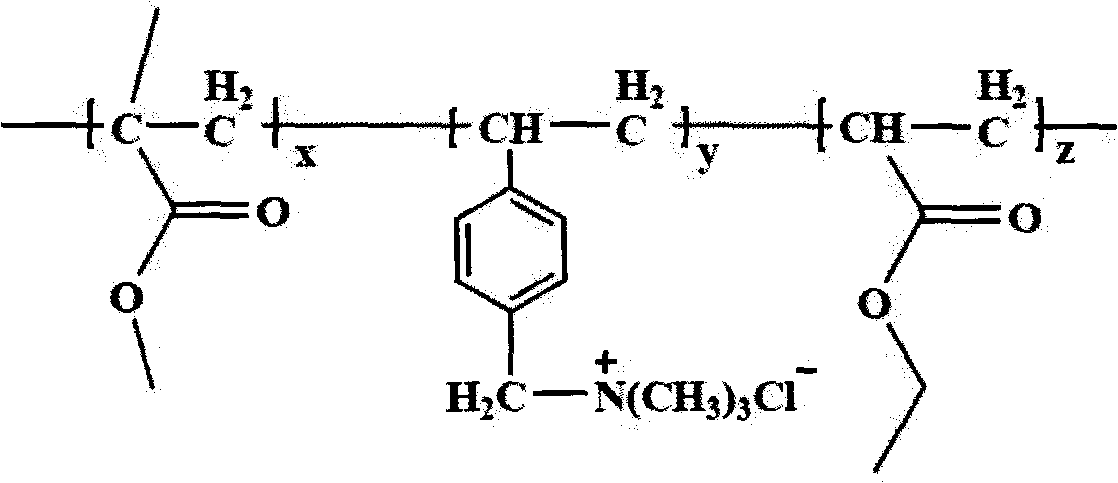

Method used

Image

Examples

Embodiment 1

[0022] 1) Add methyl methacrylate, vinyl benzyl chloride, toluene and azobisisobutyronitrile (wherein methyl methacrylate and vinyl benzyl chloride are mixed in a volume ratio of 1:1) in a three-necked flask, Under the protection of nitrogen, heat to 45° C. for reflux reaction for 5 h, the product is precipitated with methanol, washed and dried to obtain a chloromethyl-containing copolymer.

[0023] 2) Dissolve the copolymer in tetrahydrofuran, let it stand for degassing, and obtain 5% casting solution, cast the casting solution on a glass plate, dry it at 60-70°C for 8 hours, and put it into deionized water after cooling for immersion Until the film falls off the glass plate, the film is then air-dried naturally.

[0024] 3) Soak the membrane in an aqueous solution of triethylamine for 10 h at room temperature, and rinse it with deionized water several times until neutral.

[0025] 4) The membrane was immersed in 1M hydrochloric acid aqueous solution for 24 hours, and then r...

Embodiment 2

[0027] 1) Add methyl methacrylate, ethyl methacrylate, vinyl benzyl chloride, toluene and azobisisobutyronitrile (wherein methyl methacrylate, ethyl methacrylate, vinyl benzyl The volume ratio of chlorine is 2:2:5). Under the protection of nitrogen, it was heated to 65° C. for reflux reaction for 20 h, and the product was precipitated with methanol, washed and dried to obtain a chloromethyl-containing copolymer.

[0028] 2) Dissolve the copolymer in N,N-dimethylformamide, let it stand for defoaming, and obtain a 6% casting solution, cast the casting solution on a glass plate, and dry it at 60-70°C for 8 hours, After cooling, soak in deionized water until the film falls off the glass plate, and then air-dry the film naturally.

[0029] 3) Soak the membrane in an aqueous solution of trimethylamine for 8 hours at room temperature, and rinse with deionized water several times until neutral. 4) Dip the film in 1M hydrochloric acid aqueous solution for 24 hours, rinse it with deio...

Embodiment 3

[0031] 1) Add butyl methacrylate, vinylbenzyl chloride, toluene and benzoyl peroxide (wherein butyl methacrylate and chloromethyl styrene are mixed in a volume ratio of 1:0.8) in a three-necked flask. Under the protection of nitrogen, it was heated to 80° C. for reflux reaction for 20 h, and the product was precipitated with methanol, washed and dried to obtain a chloromethyl-containing copolymer.

[0032] 2) Dissolve the copolymer in N,N-dimethylacetamide, let it stand for defoaming, and obtain a 10% casting solution, cast the casting solution on a glass plate, and dry it at 60-70°C for 8 hours, After cooling, soak in deionized water until the film falls off the glass plate, and then air-dry the film naturally.

[0033] 3) Soak the membrane in an aqueous solution of triethylamine for 10 h at room temperature, and rinse it with deionized water several times until neutral.

[0034] 4) The membrane was immersed in 1M hydrochloric acid aqueous solution for 24 hours, and then rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com