Silica tube for growing semi-insulated gallium arsenide and method for doping carbon in gallium arsenide

A gallium arsenide and quartz tube technology, which is applied in the VGF field of high-performance compound semiconductor SI-GaAs single crystal, can solve the problems of atmosphere doping and quartz tube structure that cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose of the present invention is to provide an atmosphere C-doped method for growing semi-insulating gallium arsenide by the vertical gradient solidification technology of the quartz tube-PBN system, which has the advantages of easier control of C concentration and better electrical uniformity of the material.

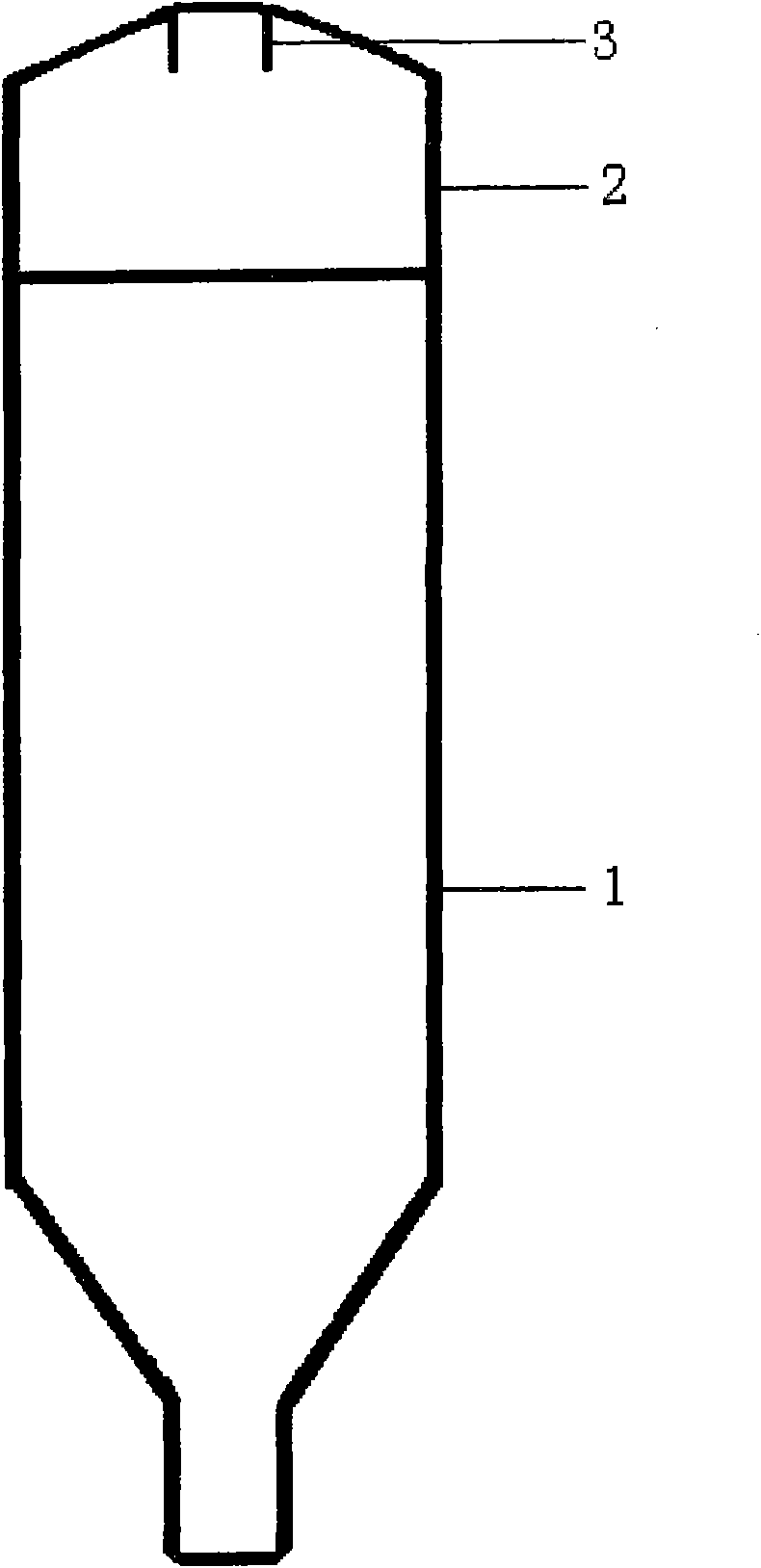

[0029] In order to achieve the above object, the present invention provides a new quartz tube structure, please refer to figure 1 As shown, it includes: a quartz body 1 and a quartz cap 2 covered therewith, wherein a quartz groove 3 is fixed on the inner top of the quartz cap 2; it is characterized in that:

[0030] The height of the cover quartz groove 3 is less than the depth of the quartz cap 2; this can avoid the oxidation of graphite in the welded quartz tube stone; the position of graphite in the quartz tube can be quantified by the depth of the quartz groove 3, and it can be realized by adding a verified temperature field heating temperature.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com