Thin-film transistor substrate, electronic device and preparation method thereof

A technology of thin-film transistors and substrates, applied in transistors, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor electrical uniformity, and achieve the effect of good electrical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The technical solutions of the present invention will be further described in more detail in conjunction with the accompanying drawings and specific embodiments.

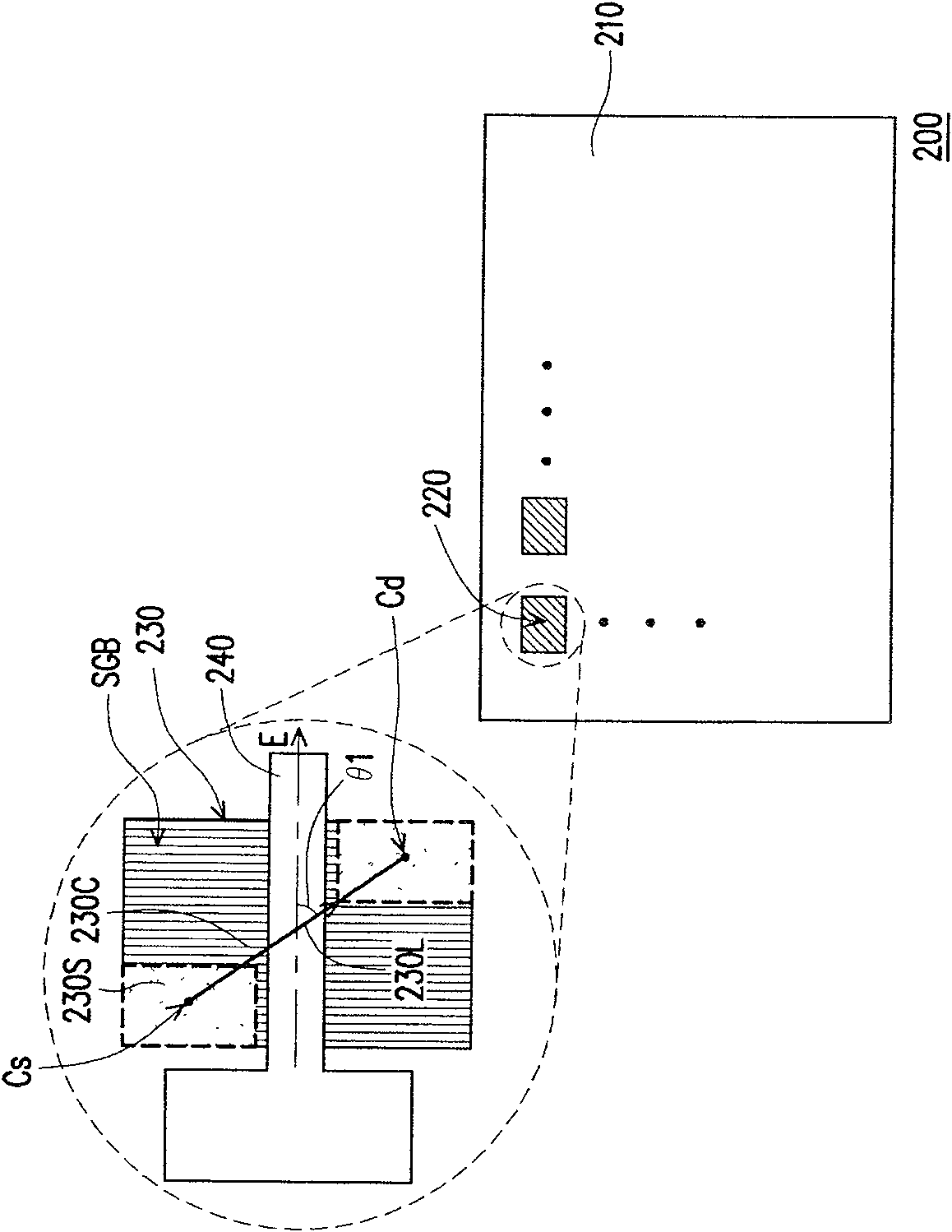

[0086] image 3 It is a schematic top view and a partially enlarged view of the thin film transistor array substrate according to the first embodiment of the present invention. Please refer to image 3 , the thin film transistor array substrate 200 includes a substrate 210 and at least one thin film transistor 220 disposed on the substrate 210, wherein the thin film transistor 220 includes a semiconductor island 230 and at least one gate 240, and the semiconductor island 230 has a source region 230S, The drain region 230D and the channel region 230C located between the source region 230S and the drain region 230D, wherein the material of the semiconductor island 230 can be polycrystalline, monocrystalline or microcrystalline composed of silicon; Or the polycrystalline form, single crystal form or microcryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com