Large-diameter CdTe or CdZnTe polycrystalline rod synthesis apparatus and preparation method thereof

A technology of polycrystalline rods and synthesis devices, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth, can solve the problems of unsuitability for large-scale production, complex synthesis methods, and high costs, and prevent secondary less pollution, easy to manufacture, and lower mass production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings.

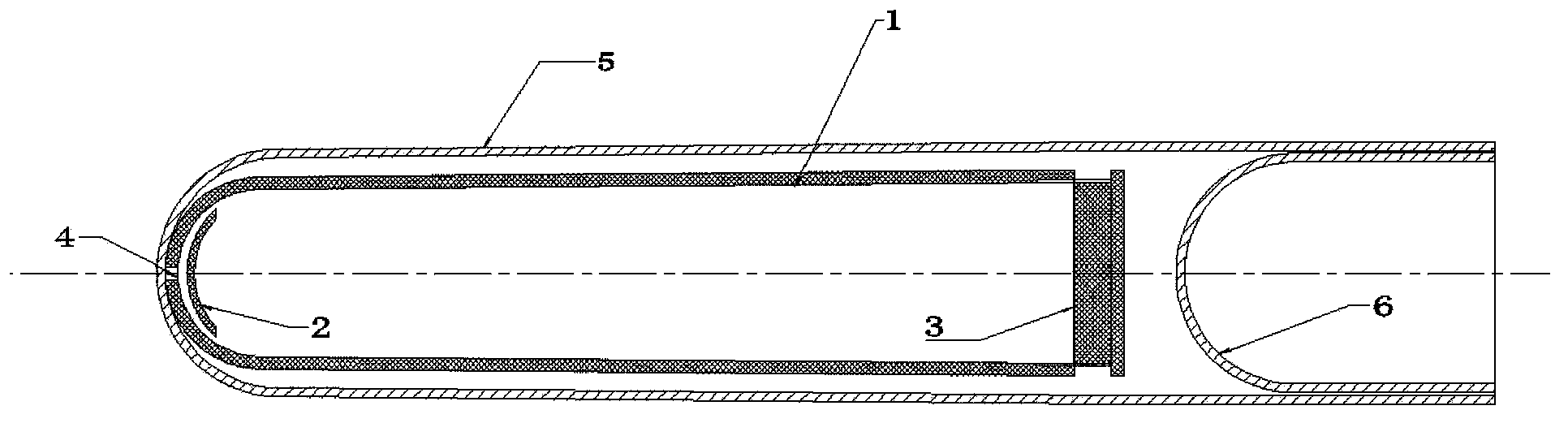

[0031] Such as figure 1 As shown, the device of the present invention comprises: a graphite crucible 1, a quartz crucible 5, a graphite gasket 2, a graphite cover 3, a quartz plug 6, the bottom of the graphite crucible 1 is provided with an air extraction hole 4, and the graphite gasket 2 is placed on the bottom of the graphite crucible 1 , the graphite cover 3 is located at the mouth of the graphite crucible 1, the graphite crucible 1 is placed in the quartz crucible 5 as a whole, and has a corresponding gap with the quartz plug 6, and the quartz plug 6 is located at the 5 mouth of the quartz crucible. The quartz plug and the quartz crucible are sealed by welding. The graphite crucible is a high-purity graphite crucible with a purity of not less than 99.99999%. The described quartz crucible is a high-purity quartz crucible, the purity of which is no less than 99.99%. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com