Micro-hydrogen injection energy-saving exhaust-reduction device of internal combustion engine

A technology for internal combustion engines, hydrogen and oxygen, applied to internal combustion piston engines, combustion engines, charging systems, etc., can solve problems such as complex structures, and achieve the effects of improved safety, high reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

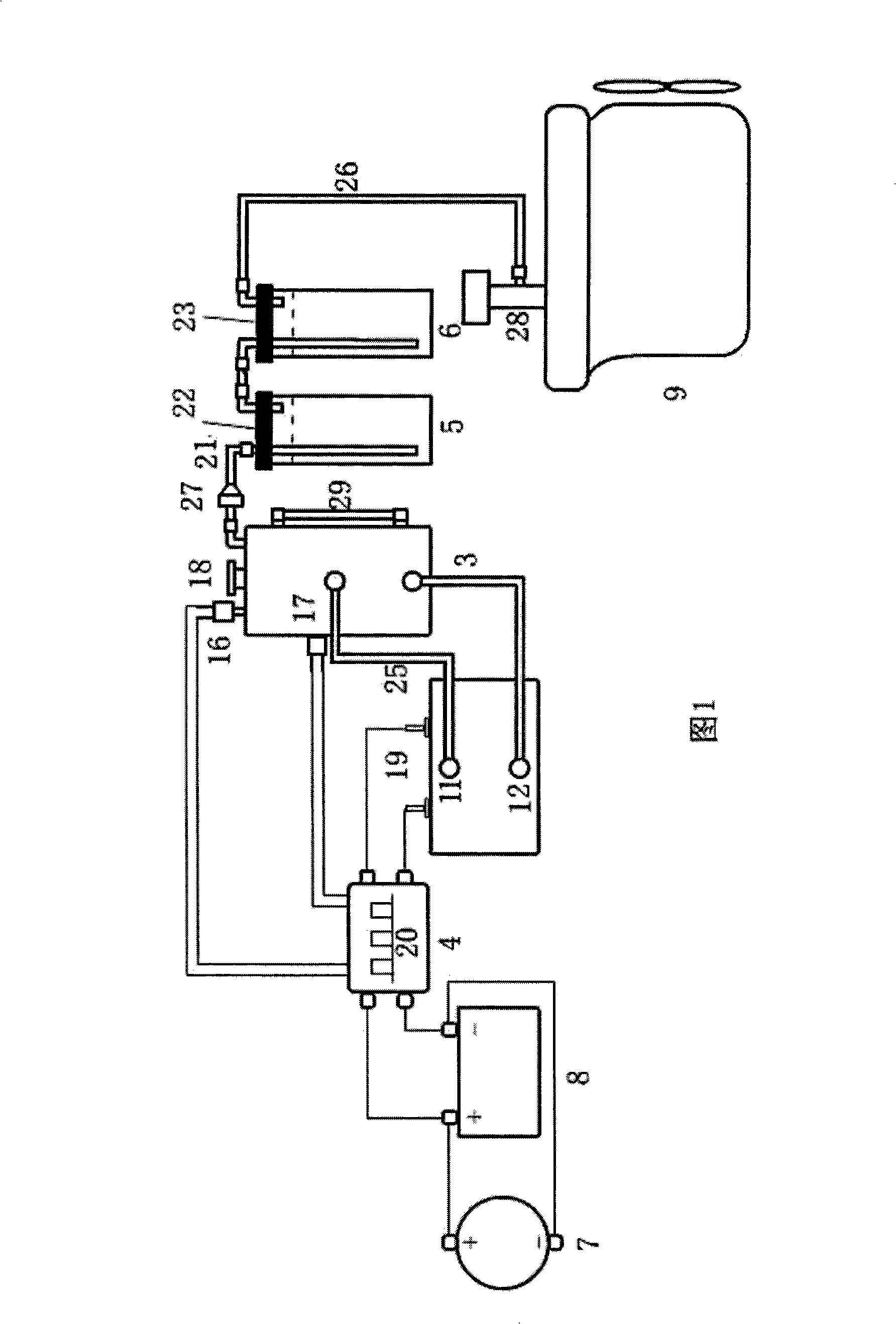

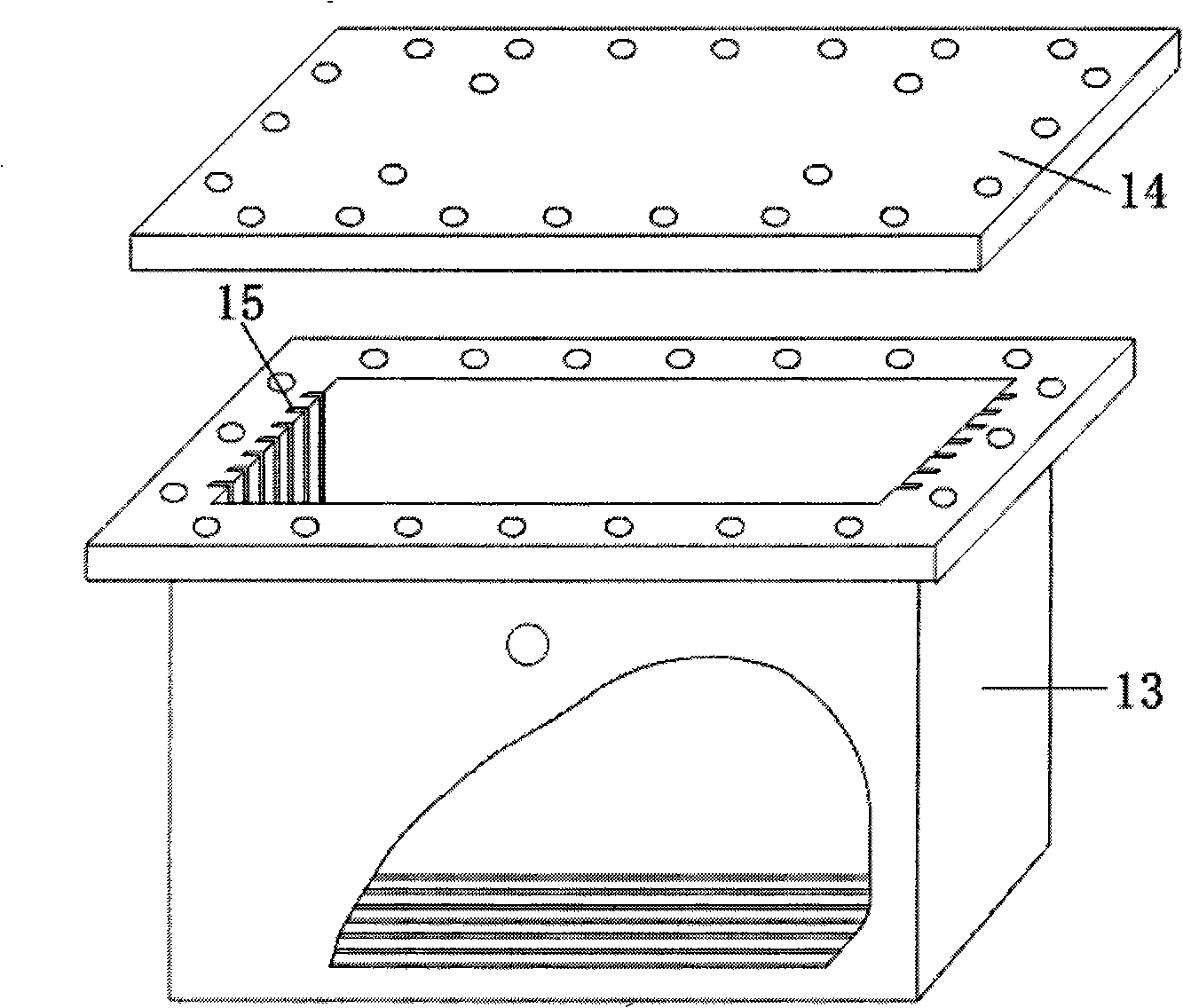

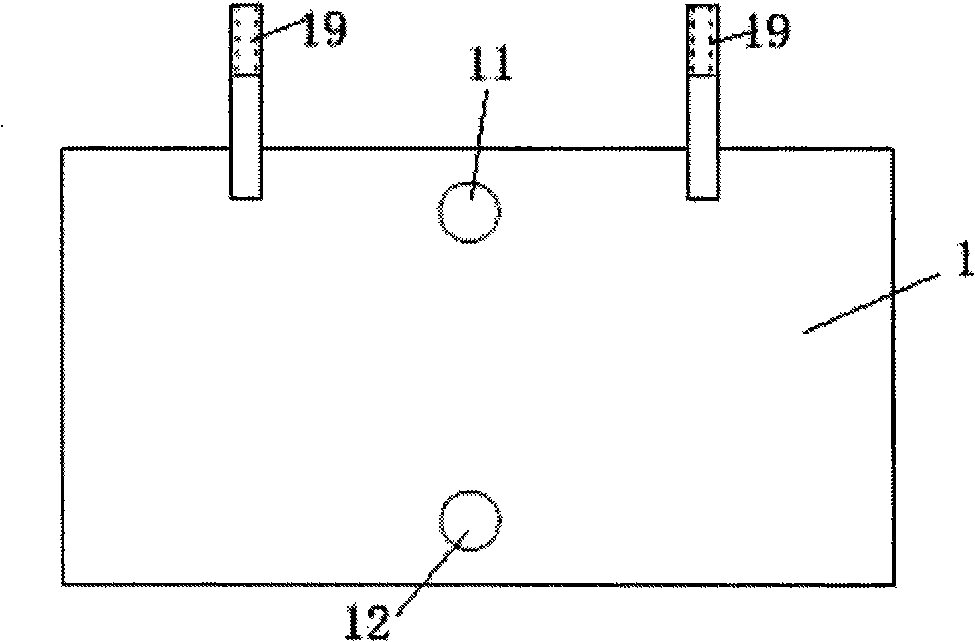

[0022] Figure 1, figure 2 As shown, the present invention includes: a hydrogen-oxygen electrolytic cell 2, an electrolyte storage tank 3, a current pulse width modulation gas volume control and safety protection circuit 4, a gas washing tank 5, a water-sealed anti-tempering tank 6, and is characterized in that: a generator 7 The positive and negative connections of the conductive electrode plate 1 of the hydrogen-oxygen electrolytic cell 2 with the parallel storage battery 8 through the current pulse width modulation gas volume control and safety protection circuit 4; the casing 13 of the hydrogen-oxygen electrolytic cell 2 has two holes ( 11,12), the lead-out pipelines from the two holes (11,12) of the hydrogen-oxygen electrolytic cell 2 are connected with the electrolyte liquid storage tank 3, the gas washing tank 5, the water seal anti-tempering tank 6, and the internal com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com