Coaxial wire feeding and powder feeding melting pole arc additive manufacturing device and process

A technology of additive manufacturing and coaxial wire feeding, applied in manufacturing tools, additive processing, additive manufacturing, etc., can solve the problems of poor printing stability, large heat input, large thermal stress deformation, etc. uniformity, reducing the effect of excessive heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

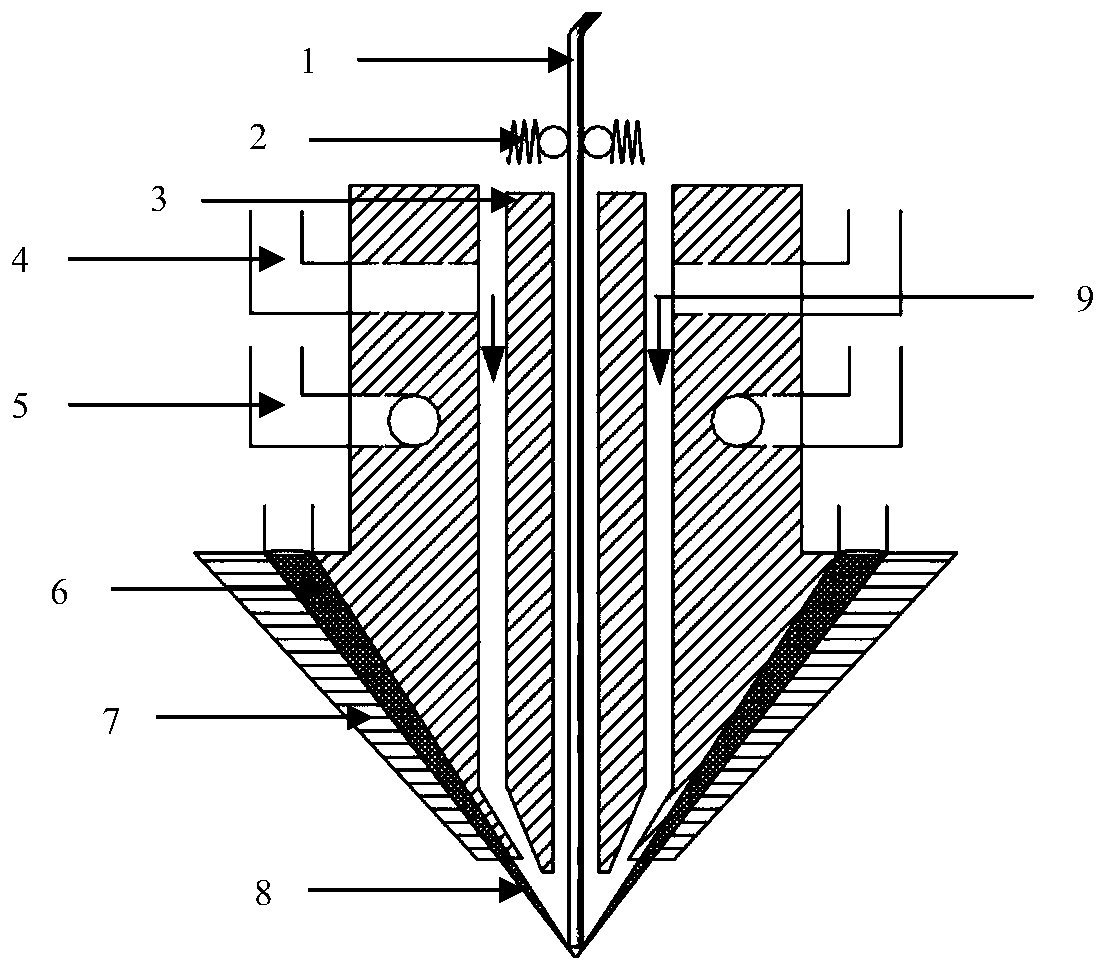

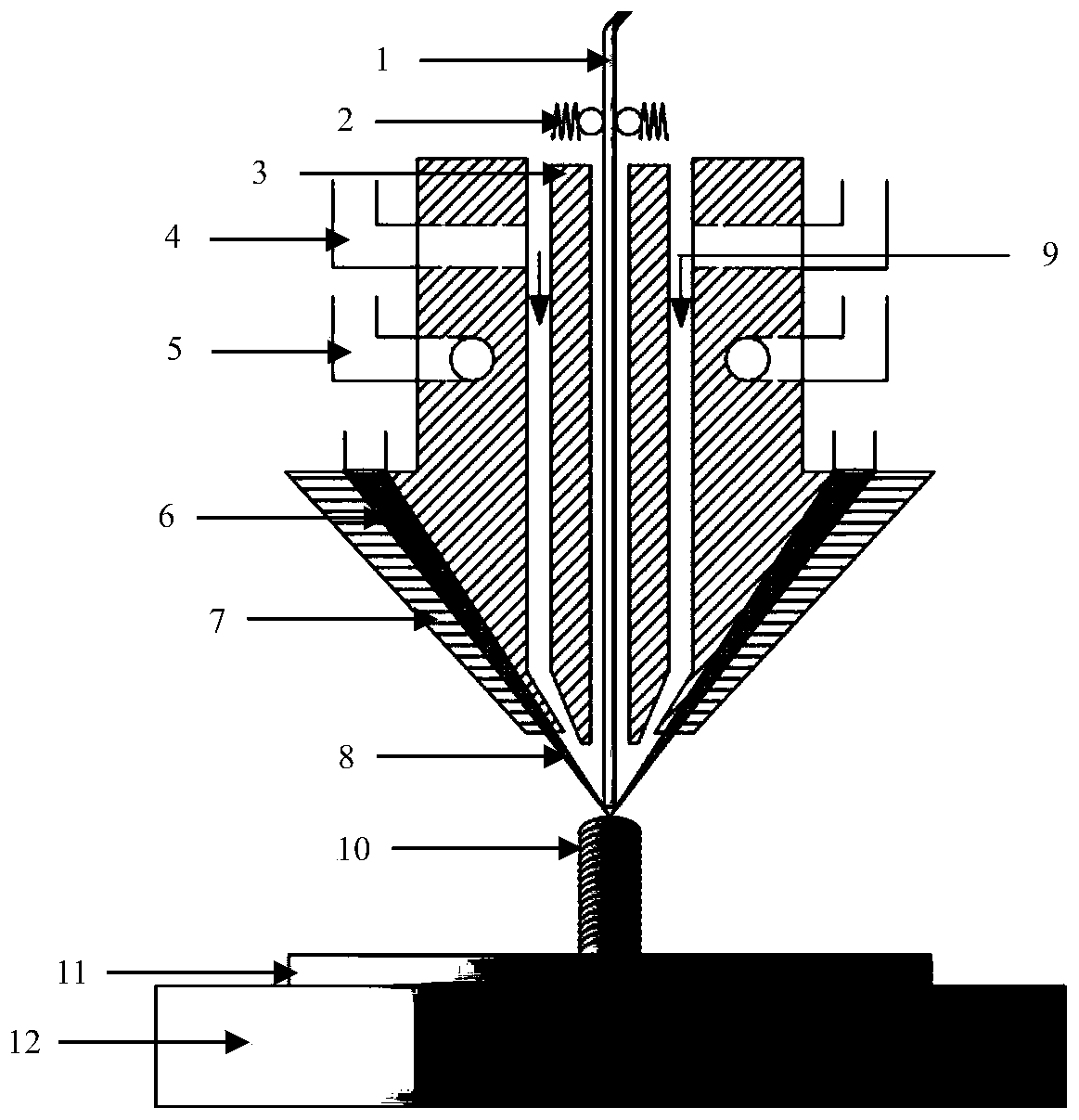

[0025] A coaxial wire feeding powder feeding melting electrode arc additive manufacturing device, the central body through which the welding wire (1) passes passes through the center of the four-way powder feeding nozzle (7), the welding wire (1), the central body and the four-way feeding The powder nozzle (7) adopts coaxial design, and the four-way powder feeding nozzle (7) is connected with the external powder feeder, and gathers around the central body (3) (such as figure 1 and 2 shown, surrounded around the bottom of the central body), the four-way powder feeding nozzle (7) (such as figure 1 and 2 As shown, the powder feeding channel (6) arranged in the lower part of the four-way powder feeding nozzle (7) adopts a cone design, and an annular protective gas channel is formed between the central body (3) and the four-way powder feeding nozzle (7) (9), during the printing process, the bottom outlet of the shielding gas channel (9) and the alloy powder and welding wire eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com