Meat cutting mechanism

A technology of fixed motor and rotating pair, which is applied in the direction of grain processing, etc., can solve the problems of easily suffering from arthritis, affecting the taste of meat, and long duration, etc., and achieve the effect of compact and ingenious design, fast chopping and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

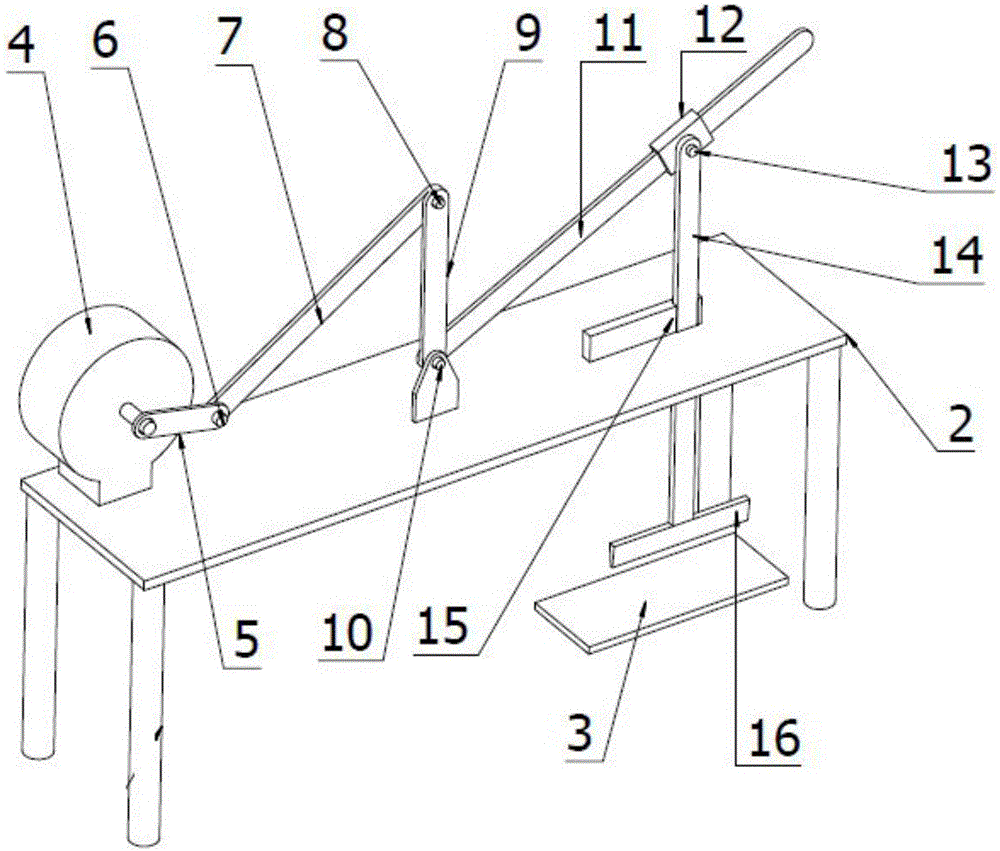

[0012] A meat chopping mechanism, comprising a workbench 2, a chopping board 3, a motor 4, a crank 5, a first rotating pair 6, a connecting rod 7, a second rotating pair 8, a rocker 9, a third rotating pair 10, a pendulum 11, and a slider 12 , rotating pair four 13, guide rod 14, chute 15 and chopping knife 16,

[0013] The motor 4 is fixed on the workbench 2, one end of the crank 5 is fixedly connected with the output shaft of the motor 4, the other end of the crank 5 is hinged with one end of the connecting rod 7 through a rotating pair 6, and the other end of the connecting rod 7 and one end of the rocker 9 are connected through a rotating pair Two 8 are hinged, the other end of the rocker 9 is hinged on the workbench 2 through the rotating pair 3 10, one end of the swing rod 11 is fixed on the rocking rod 9, the slider 12 slides in the swing rod 11, and one end of the guide rod 14 passes through the rotating pair 4 13 is hinged on the slider 12, the workbench is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com