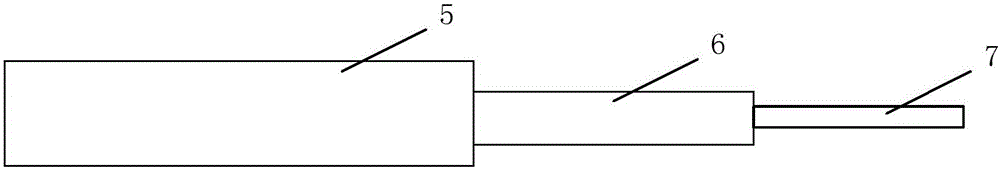

Method for preparing multi-core optical fiber coupler based on tapering self-assembly

A multi-core optical fiber and coupler technology is applied in the field of preparation of multi-core optical fiber couplers based on self-assembly of tapers, and achieves the effects of protecting pigtails, reducing insertion loss and having good scalability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] Embodiment 2 provides a preferred preparation method of a multi-core optical fiber coupler based on microhole processing. One end of the glass sleeve 2 used in step (2) can be made into a horn mouth to facilitate the insertion of optical fibers.

Embodiment 3

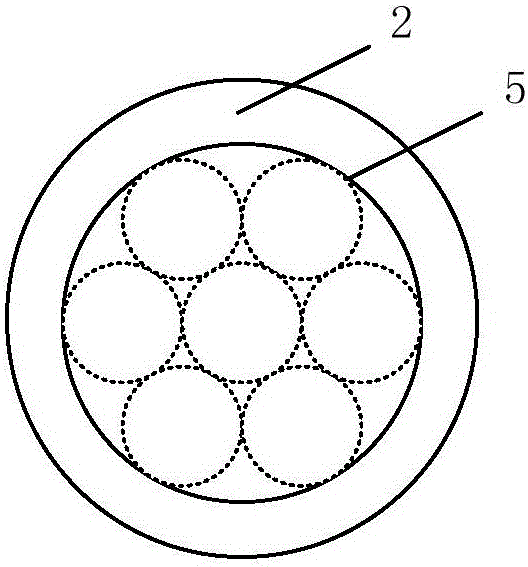

[0040] Embodiment 3 provides a kind of preferred multi-core optical fiber coupler preparation method based on microhole processing, such as Figure 6 As shown, the glass sleeve 2 used in step (2) has a circular uniform through hole, and the diameter of one end of the sleeve can be appropriately reduced by pre-tapering in step (3) to assist the arrangement of the optical fibers at the tail end of the second intermediate piece. The other end is used to protect and align the pigtails.

Embodiment 4

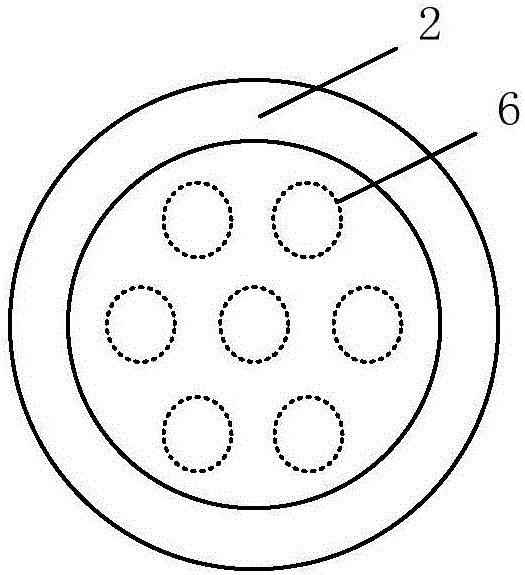

[0041] Embodiment 4 provides a kind of preferred multi-core optical fiber coupler preparation method based on microhole processing, such as Figure 7 As shown, the glass sleeve 2 adopted in step (2) has a circular uniform through hole, and the diameter of one end of the sleeve can be appropriately reduced by pre-tapering in step (3) to assist the removal of the middle part of the second intermediate piece. Fiber alignment, and then continue to reduce the diameter of this end to assist the fiber alignment of the corroded part of the second intermediate piece, and the other end is used to protect and arrange the pigtails.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com