Method for preparing graphene powder and graphene transparent conductive film by oxyhydrogen flame method

A technology of transparent conductive film and graphene powder, which is applied in the direction of graphene, nano-carbon, etc., can solve the problems of destroying the quality of graphene, reducing the quality of graphene, and low controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

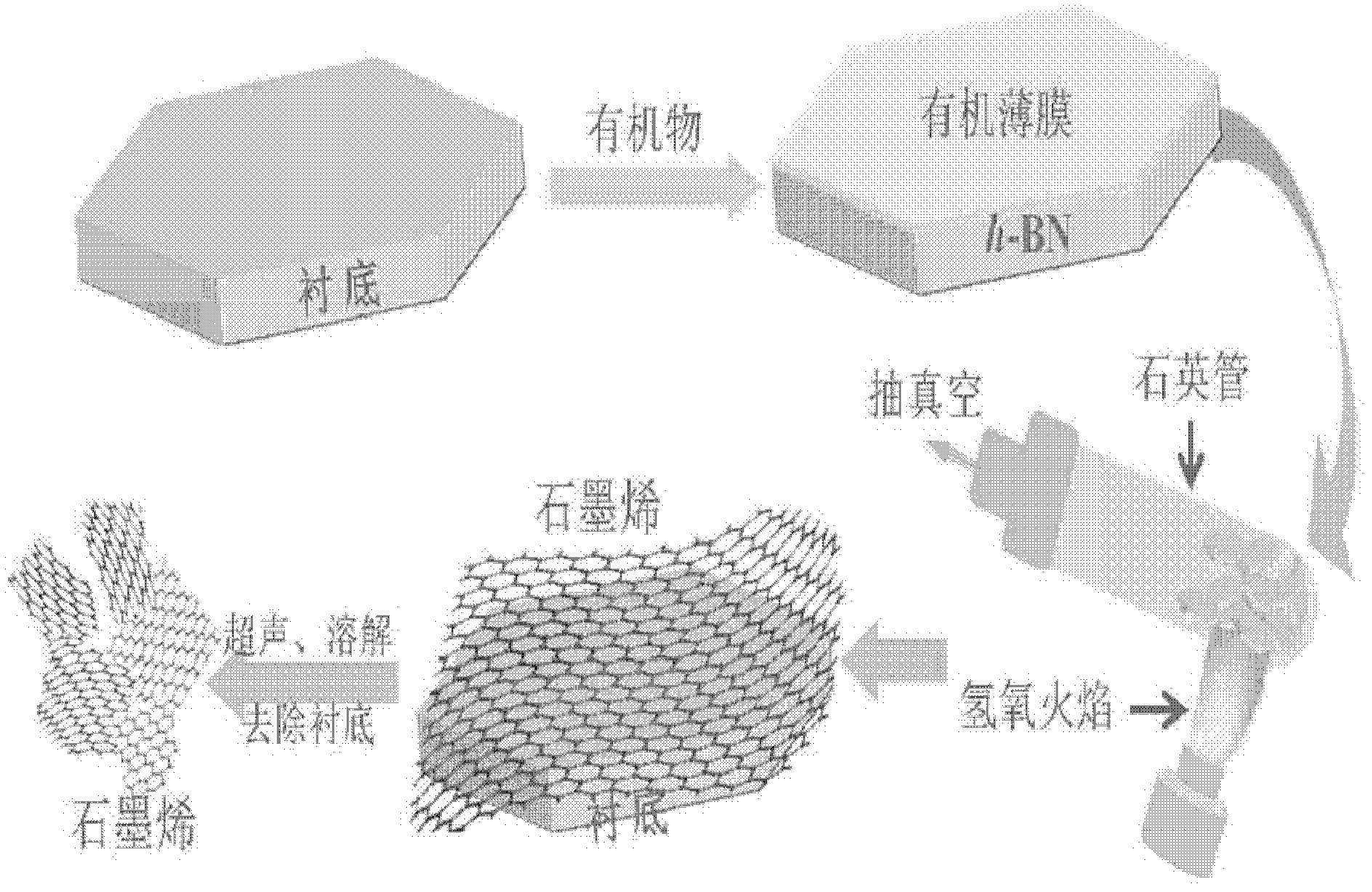

[0058] Direct growth of graphene powder on h-BN insulating substrate

[0059] Implementation process such as figure 1 As shown, 2 L of anisole solution of PMMA with a mass fraction of 6% was first prepared for later use.

[0060] Take 100 mL of 6% PMMA anisole solution and 5 g of h-BN powder, stir for 30 minutes, place in an oven at 120° C. for 2 hours to fully evaporate the solvent, and obtain PMMA-coated h-BN. The aforementioned PMMA-coated h-BN was packed into a quartz tube with a size of φ25×2mm. Evacuate to 100Pa, and quickly heat the quartz tube with a hydrogen-oxygen flame for 20 seconds. Afterwards, the oxyhydrogen flame was removed and the quartz tube was allowed to cool rapidly to room temperature. The samples were taken out to obtain h-BN / graphene composites.

[0061] Conductivity test of graphene grown directly on h-BN insulating substrate

[0062] Conductivity is an important index to characterize the quality of graphene. In order to measure the conductivity...

Embodiment 2

[0069] Preparation of Freestanding Graphene

[0070] In order to obtain pure graphene, on the basis of Example 1, the present invention puts 6.7 g of the obtained h-BN / graphene composite into 400 mL of ethanol, and obtains a turbid solution after ultrasonication at 300 w for 15 minutes. . After centrifugation at 1000 rpm for 5 minutes, 1.5 g of pure unsupported graphene samples were obtained.

[0071] The unsupported graphene obtained by the present embodiment is modulated into a conductive paste, scraped into a 10 μm film according to the method in Example 1, and silver paste is applied to test that its average sheet resistance is 31Ωsq (ohm / square).

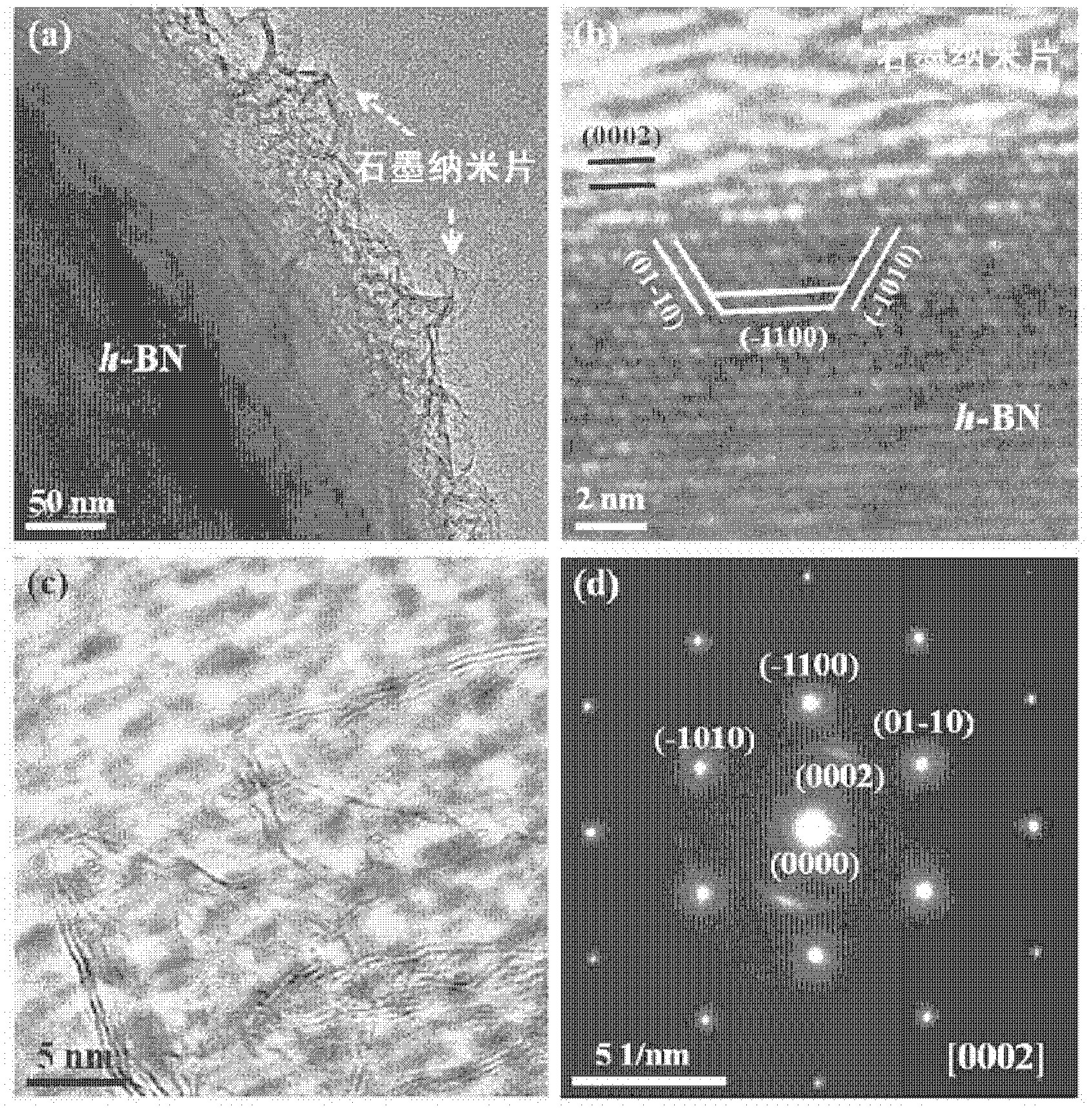

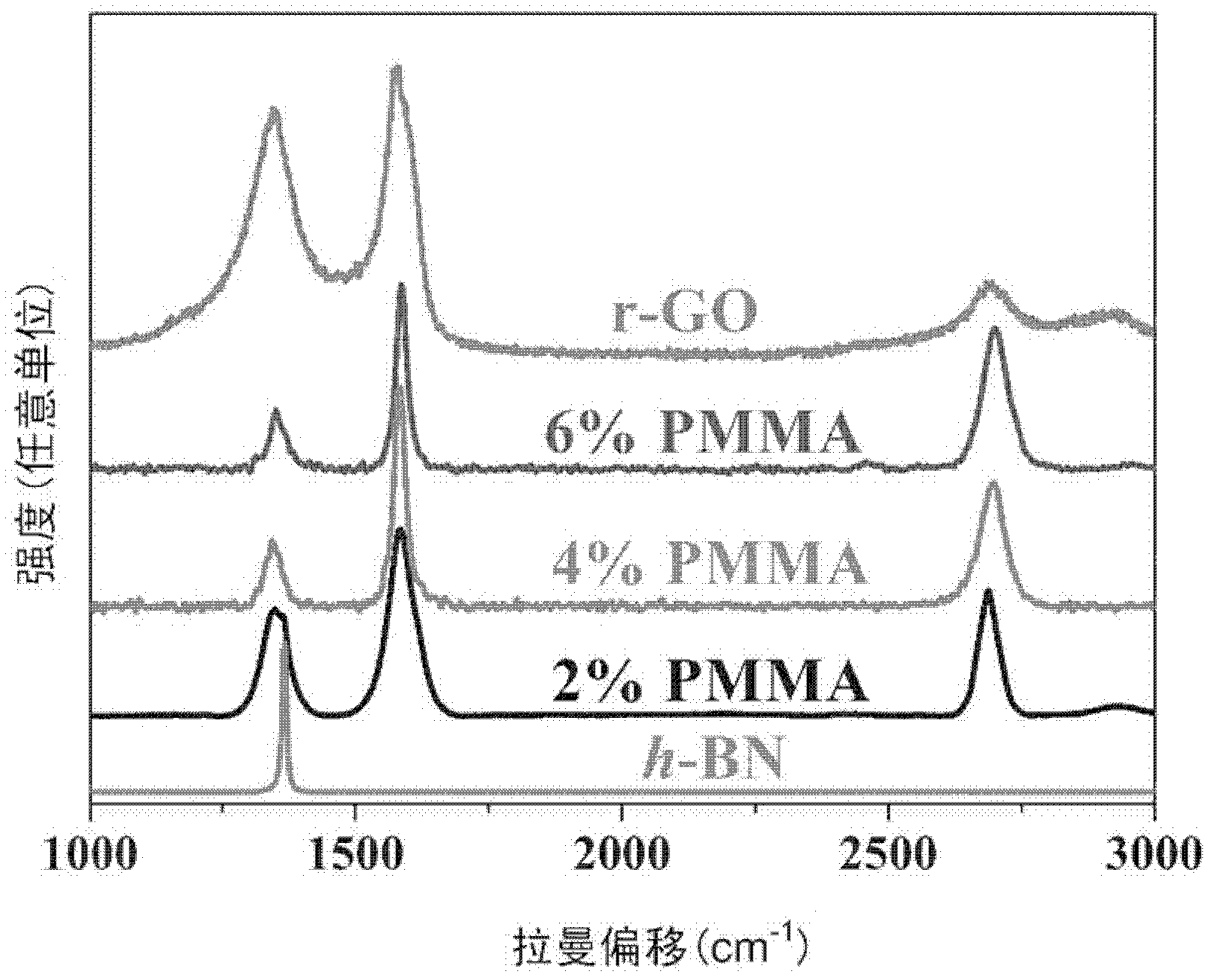

[0072] Characterization of Morphological and Structural Properties

[0073] The morphology of the obtained unsupported graphene observed with a transmission electron microscope, such as Figure 7 shown. It can be seen from the figure that the obtained graphene has a size of 200 nm. Observing the graphene boundary with a hi...

Embodiment 3

[0086] Prepare 2 L of anisole solution of PMMA with a mass fraction of 4% for later use.

[0087] Take 200 mL of 4% PMMA anisole solution and 5 g of h-BN powder, stir for 20 minutes, place in an oven at 120° C. for 3 hours to fully evaporate the solvent, and obtain PMMA-coated h-BN. The aforementioned PMMA-coated h-BN was packed into a quartz tube with a size of φ25×2mm. Evacuate to 100Pa, and quickly heat the quartz tube with a hydrogen-oxygen flame for 15 seconds. Afterwards, the oxyhydrogen flame was removed and the quartz tube was allowed to cool rapidly to room temperature. The samples were taken out to obtain h-BN / graphene composites.

[0088] In order to obtain pure graphene, on the basis of the above-mentioned h-BN / graphene composite, 7.1 g of the obtained h-BN / graphene composite was placed in 800 mL of ethanol, and after ultrasonication at 400 w for 15 minutes A cloudy solution was obtained. After centrifugation at 1000 rpm for 5 minutes, 1.7 g of pure unsupported...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average resistance | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com