High strength spring steel wire with excellent coiling properties and hydrogen embrittlement resistance

A technology of spring steel wire and hydrogen embrittlement resistance, applied in the field of spring steel wire, can solve the problems of enhancing coilability and hydrogen embrittlement resistance, which have not been raised, and achieve the effect of enhancing hydrogen embrittlement resistance, low cost, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] Hereinafter, the present invention will be described in detail with reference to the invention and comparative examples. It should be noted that the present invention is not limited to these embodiments, and modifications and changes of the embodiments can be made without departing from the scope of the present invention.

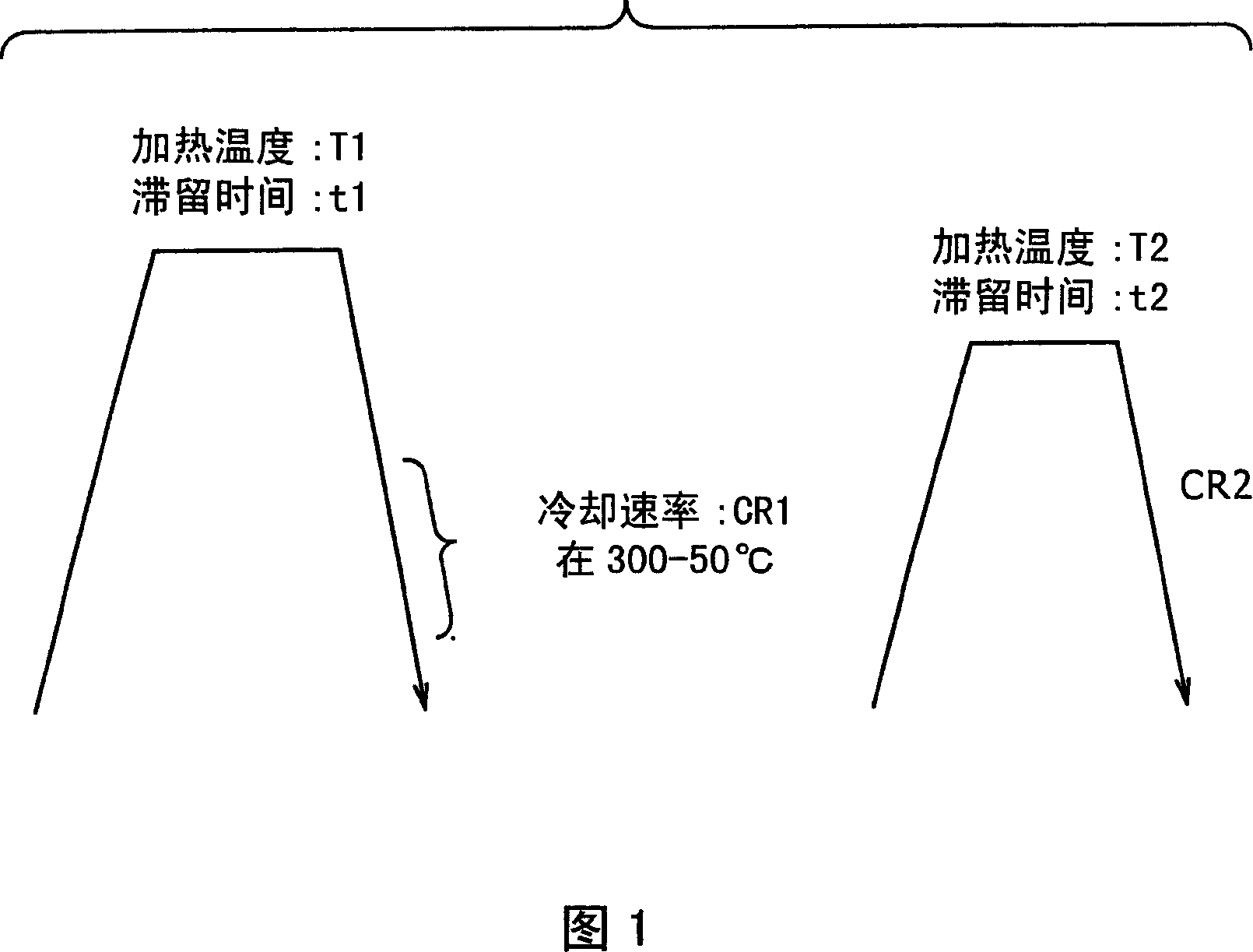

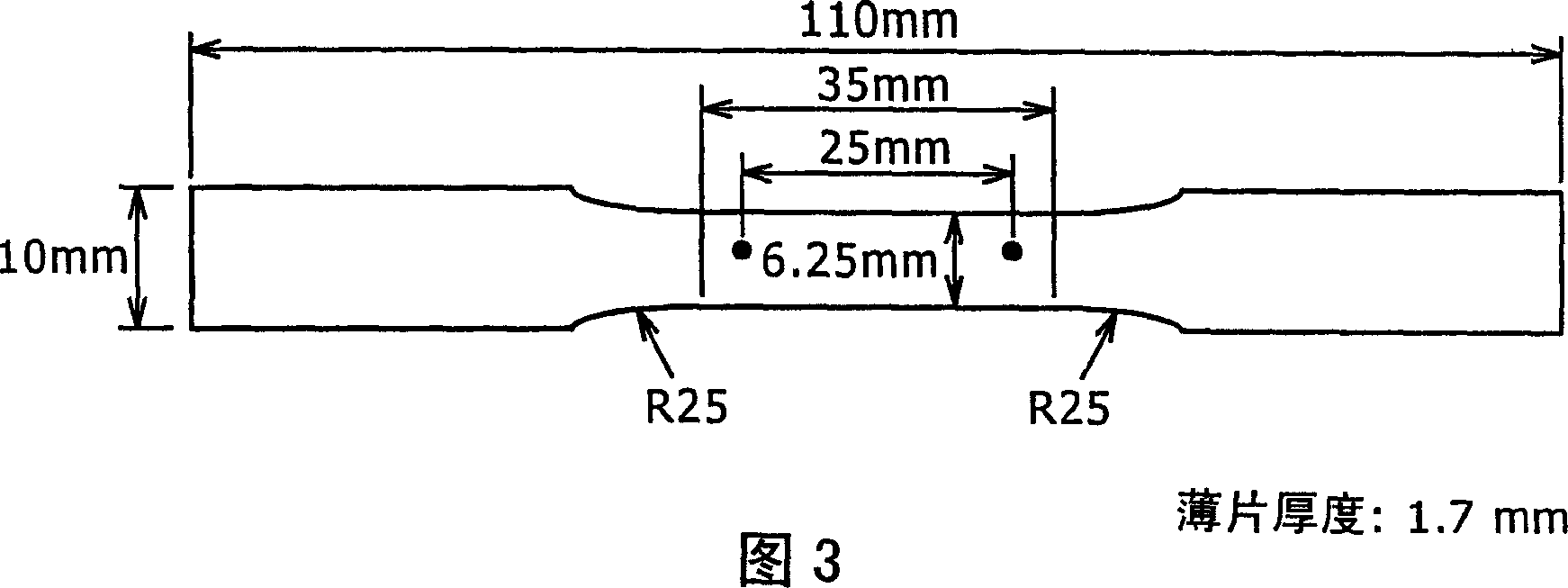

[0087] After forming steels A1 to A33 having the compositions listed in Table 1 from molten metal, steel rods of φ14 mm were obtained by hot rolling. Then, in order to evaluate the properties, each steel bar was cut into a length of 200 mm, subsequently quenched and tempered under the conditions listed in Tables 2 and 3 (T1, t1, CR1, T2, t2 and CR2 indicates the marker in Figure 1). Quenching and tempering are carried out using electric furnace, salt kettle or IH furnace.

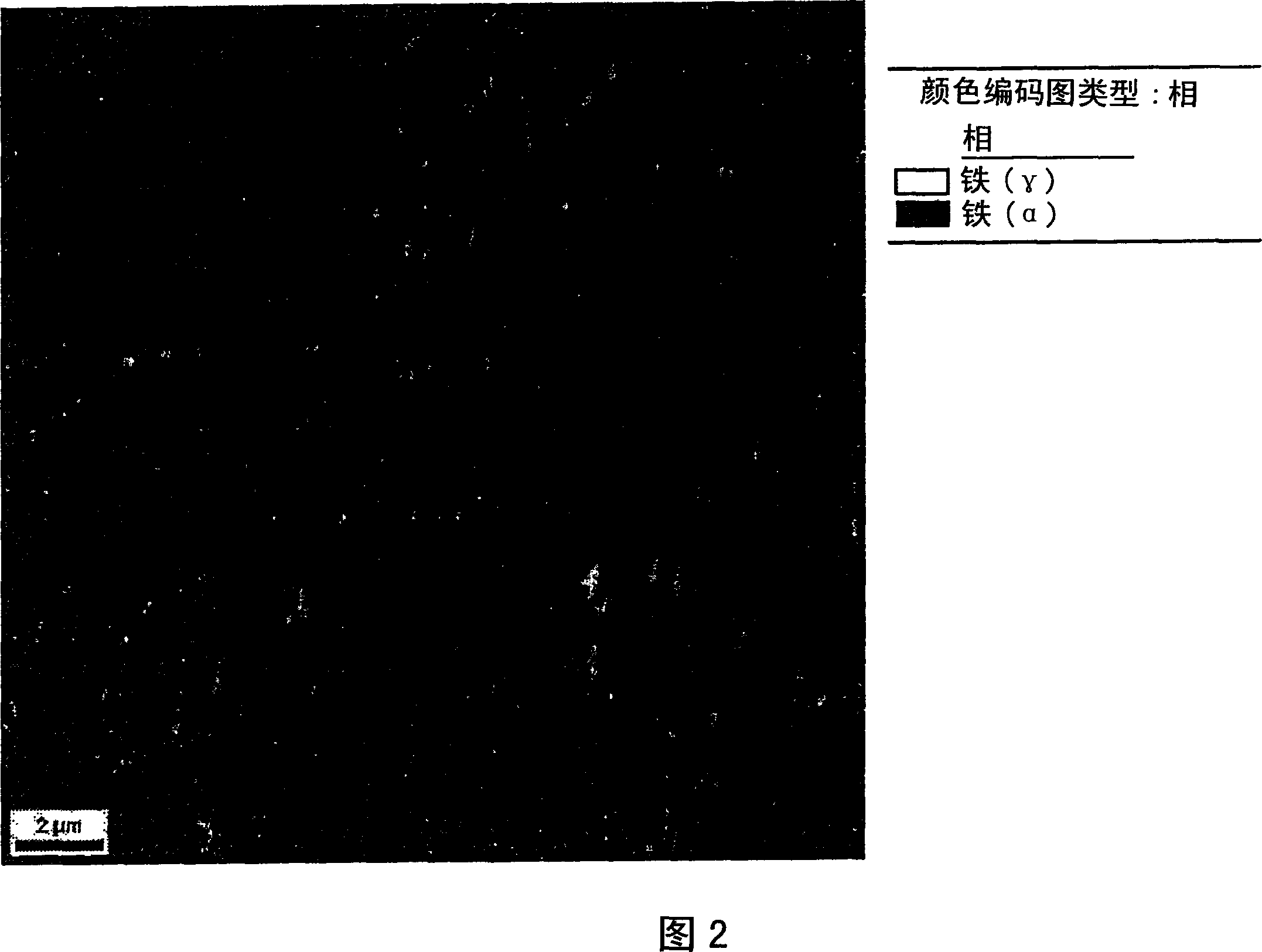

[0088] In these examples, the average grain size of prior austenite was adjusted by controlling the treatment conditions for quenching, and at the same time, the amount and size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com