Hydrogen sensitive material for optical fiber hydrogen sensor and preparation method of hydrogen sensitive material

A sensor and hydrogen technology, applied in the field of hydrogen sensors, can solve the problems of low signal sensitivity, slow response time, limited application, etc., and achieve the effects of high sensitivity, fast response speed, and good resistance to hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

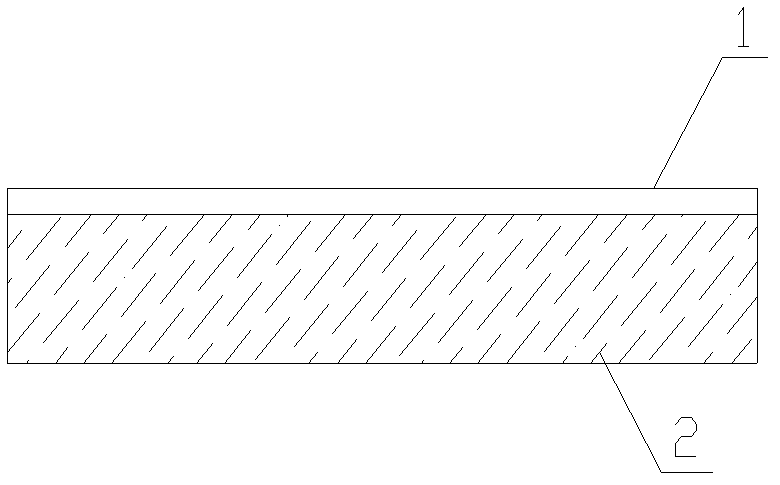

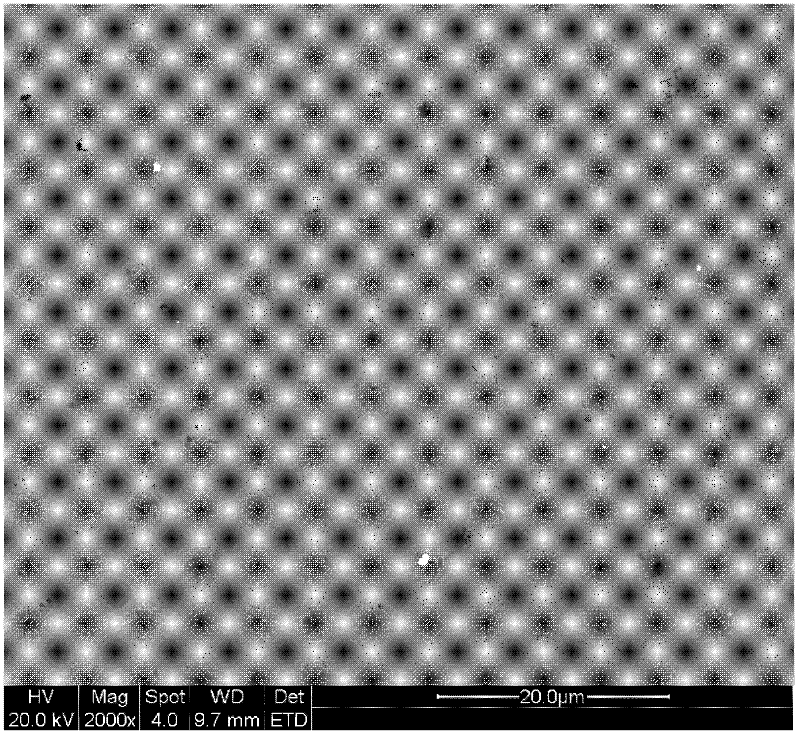

[0025] Alloy target made by induction melting or powder metallurgy, the composition is Pd 0.8 Y 0.2 . Alloy thin film materials are made on glass by magnetron sputtering, such as Figures 1 to 3 As shown, the thickness of the alloy thin film material is 50nm. figure 1 It is a schematic diagram of the structure of the hydrogen-sensitive material. figure 2 It is the appearance diagram of the glass substrate after coating. image 3 is the scanning electron microscope image of the alloy film. The hydrogen-sensitive film is combined with a light source system, an optical fiber light transmission system and a signal detection system to make an optical fiber hydrogen sensor. The hydrogen concentration is detected by the change of the reflectance of the film. Figure 4 It is the output response of the sensor when the hydrogen-sensitive film is passed repeatedly and 4% hydrogen is released.

Embodiment 2

[0027] Pure Pd targets (purity 99.99%) and pure yttrium targets (purity 99.99%) were prepared by induction melting or powder metallurgy. Sputtering was performed on glass by a multi-target co-sputtering device. The prepared composition is Pd 0.85 Y 0.15 alloy thin film material. The thickness of the alloy thin film material is 40nm.

Embodiment 3

[0029] Pure Pd targets (purity 99.99%) and pure yttrium targets (purity 99.99%) were prepared by induction melting or powder metallurgy. Sputtering is performed on the fiber grating by multi-target co-sputtering equipment. The prepared composition is Pd 0.85 Y 0.15 alloy film. The thickness of the alloy thin film material is 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com