High-strength steel sheet with yield strength of 1100MPa and manufacturing method thereof

A high-strength steel plate and yield strength technology, applied in the field of ultra-high-strength steel plates, can solve the problems of low-temperature impact energy of high-strength steel plates, and achieve ultra-high strength, good toughness, and loose process window effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

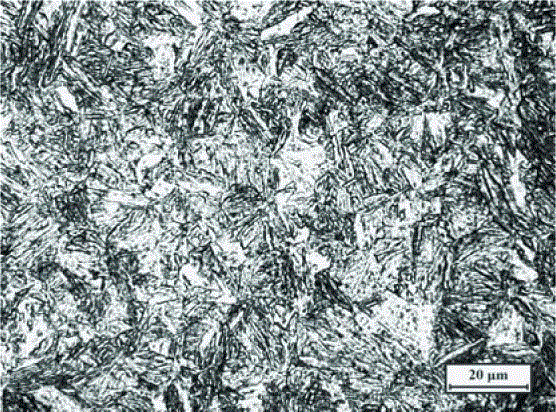

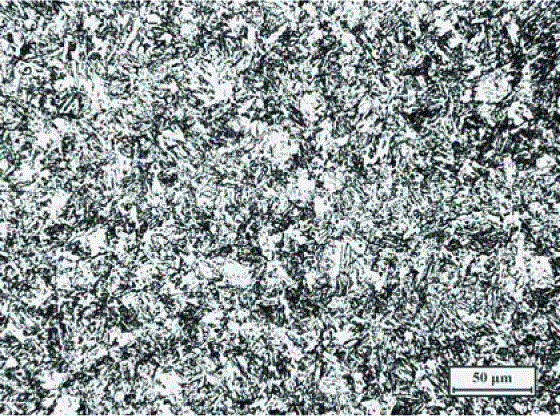

Image

Examples

Embodiment 1

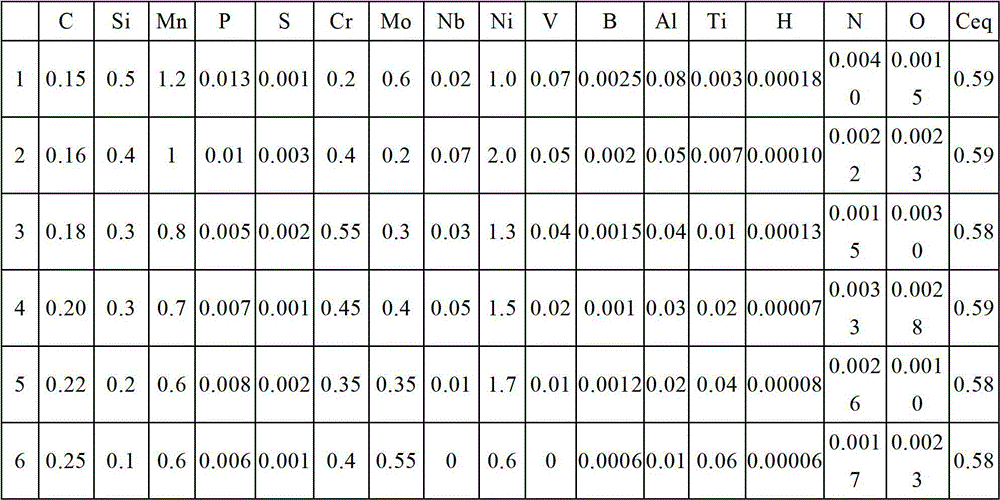

[0070] The chemical composition shown in Table 2 is smelted by electric furnace or converter, and cast into continuous casting billets or ingots. The continuous casting billets or ingots are heated to 1050 °C, the rolling temperature is 1020 °C, and the pass deformation rate is 5 to 30%. The finish rolling temperature is 860°C, and the thickness of the finished steel sheet is 8mm. Air-cooled after rolling. The quenching heating temperature is 850°C. The tempering temperature is 350°C.

Embodiment 2

[0072] The implementation is the same as in Example 1, wherein the heating temperature is 1080°C, the rolling temperature is 1060°C, the pass deformation rate is 5-30%, the final rolling temperature is 870°C, and the thickness of the finished steel plate is 10 mm. Air-cooled after rolling. The quenching heating temperature is 880°C. The tempering temperature is 320°C.

Embodiment 3

[0074] The implementation is the same as in Example 1, wherein the heating temperature is 1110°C, the rolling temperature is 1100°C, the pass deformation rate is 5-30%, the final rolling temperature is 930°C, and the thickness of the finished steel plate is 12 mm. Air-cooled after rolling. The quenching heating temperature is 900°C. The tempering temperature is 280°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com