Catalyst for preparing synthetic gas by reforming methane and carbon dioxide and preparation method thereof

A carbon dioxide and catalyst technology, applied in the field of NiO/γ-Al2O3 catalyst and its preparation, can solve the problems of metal particle migration, inability to form strong interaction, difficulty in breaking high aggregation degree, etc., and achieve the effect of long stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 6g of urea and dissolve it in deionized water to prepare a 40ml solution, add 5g of alumina to the above solution, and stir at 100°C for 12h;

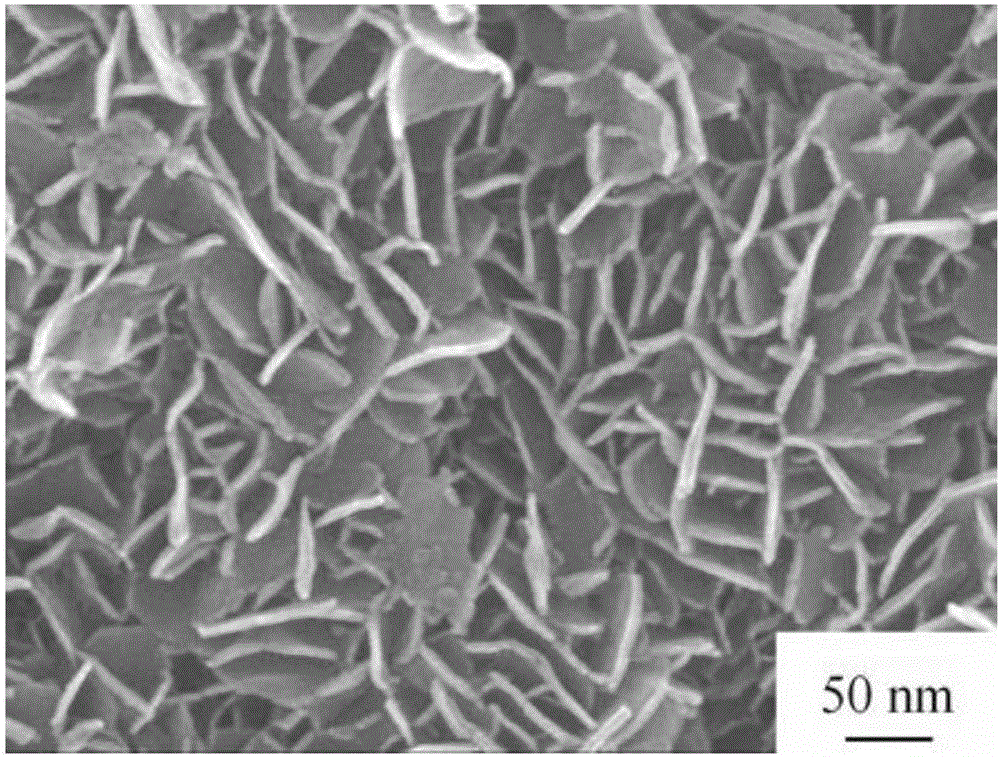

[0023] Weigh 12g of nickel nitrate and dissolve it in deionized water to prepare 20ml of solution, add it to the above-mentioned urea solution containing alumina, shake well and soak for 1-2h, put it into the reaction kettle, and crystallize it at 110°C for 14h, Cool and filter, wash with deionized water, and dry at 80°C to obtain a catalyst precursor.

[0024] Put the precursor in a muffle furnace and roast at 500°C for 8 hours, then cool to room temperature to obtain the desired catalyst NiO / γ-Al for reforming methane and carbon dioxide to produce synthesis gas 2 o 3 .

[0025] 50 mg of the catalyst was taken, mixed evenly with 50 mg of quartz sand, and packed into a fixed-bed reactor to carry out reforming experiments of methane and carbon dioxide. Into the CO in two ways 2 and CH 4 raw material gas, the total spac...

Embodiment 2

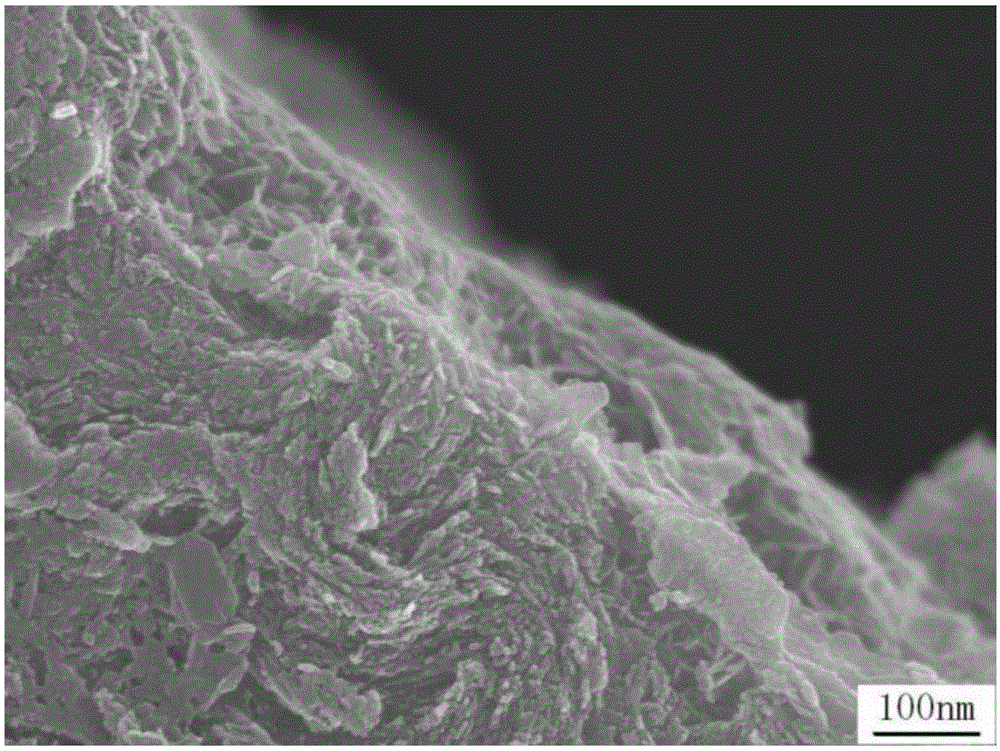

[0027] Weigh 8g of urea and dissolve it in deionized water to prepare a 30ml solution, add 5g of alumina to the above solution, and stir at 80°C for 13h;

[0028] Weigh 12g of nickel sulfate and dissolve it in deionized water to prepare 25ml of solution, add it to the above-mentioned urea solution containing alumina, shake well and soak for 1h, then put it into the reaction kettle, crystallize at 120°C for 13h, cool and filter , washed with deionized water, and dried at 80°C to obtain a catalyst precursor.

[0029] Put the precursor in a muffle furnace and roast at 700°C for 4h, then cool to room temperature to obtain the desired catalyst NiO / γ-Al for reforming methane and carbon dioxide into synthesis gas 2 o 3 .

[0030]Take 50 mg of the catalyst, mix it with 50 mg of quartz sand evenly, and carry out the methane carbon dioxide reforming experiment. CH was measured by gas chromatography 4 The conversion rate reaches 63%, CO 2 The conversion rate reached 78%, and the rea...

Embodiment 3

[0032] Weigh 4g of urea and dissolve it in deionized water to prepare a 20ml solution, add 5g of alumina to the above solution, and stir at 60°C for 12h;

[0033] Weigh 20g of nickel sulfate and dissolve it in deionized water to prepare 50ml of solution, add it to the above-mentioned urea solution containing alumina, shake well and soak for 1h, then put it into the reaction kettle, crystallize at 130°C for 10h, cool and filter , washed with deionized water, and dried at 80°C to obtain a catalyst precursor.

[0034] Put the precursor into a muffle furnace and roast at 800°C for 3.5h, then cool to room temperature to obtain the desired catalyst NiO / γ-Al for reforming methane and carbon dioxide into synthesis gas 2 o 3 .

[0035] Take 50 mg of the catalyst, mix it with 50 mg of quartz sand evenly, and carry out the methane carbon dioxide reforming experiment. CH was measured by gas chromatography 4 The conversion rate reaches 78%, CO 2 The conversion rate reached 65%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com