Novel NiAl-based solid self-lubricating composite material and preparation process thereof

A solid self-lubricating and composite material technology is applied in the field of new NiAl-based solid self-lubricating composite materials and their preparation, which can solve the problems of low wear rate of Y-TZP/tabular alumina composite ceramics, and improve the oxidation resistance. , Improve strength and ductility, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

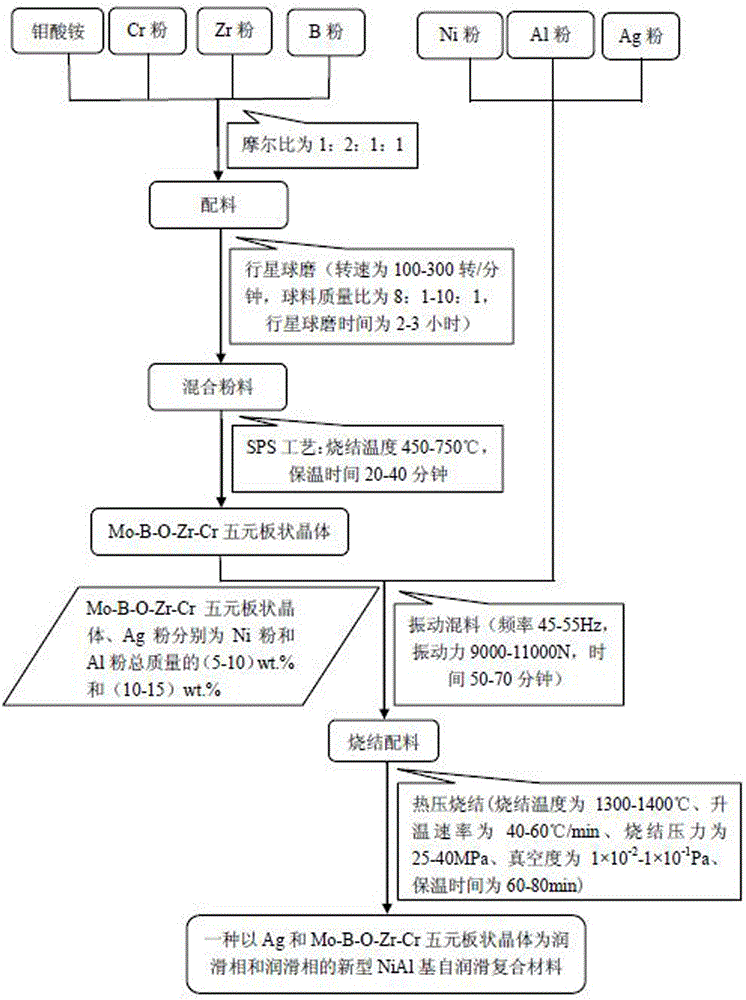

[0031] like figure 1 Shown, a kind of preparation technology of the novel NiAl-based solid self-lubricating composite material with Ag powder and Mo-B-O-Zr-Cr quinary plate crystal as lubricating phase, it comprises the following steps:

[0032] (1) According to the molar ratio of 1:2:1:1, select ammonium molybdate powder, boron powder, zirconium powder and chromium powder for ball mill mixing. The speed of the ball mill is 100 rpm, and the mass ratio of ball to material is 8:1. , the planetary ball milling time is 2 hours, and the initial mixture of Mo-B-O-Zr-Cr quinary plate crystals is obtained, and the average particle size of the initial mixture is 5 μm;

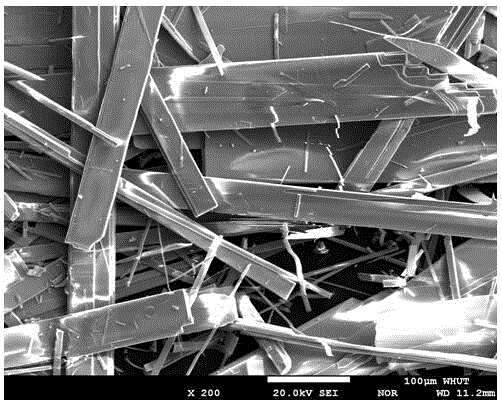

[0033] (2) The ingredients after ball milling are sintered by spark plasma sintering equipment. The sintering process is 450°C for 40 minutes, the protective gas is nitrogen, and the oxygen flow rate is 50mL / min to obtain the Mo-B-O-Zr-Cr five-component board shaped crystals with a thickness of 2 μm and a length of 110...

Embodiment 2

[0039] The preparation technology of the novel NiAl base solid self-lubricating composite material of the present embodiment, it comprises the steps:

[0040] (1) According to the molar ratio of 1:2:1:1, select ammonium molybdate powder, boron powder, zirconium powder and chromium powder for ball mill mixing. The speed of the ball mill is 300 rpm, and the mass ratio of ball to material is 10:1. , the planetary ball milling time is 3 hours, and the initial mixture of Mo-B-O-Zr-Cr quinary plate crystals is obtained, and the average particle size of the initial mixture is 15 μm;

[0041] (2) The ingredients after ball milling were sintered by spark plasma sintering equipment. The sintering process was 750°C for 20 minutes, and the protective gas was nitrogen to obtain the Mo-B-O-Zr-Cr five-element plate-shaped crystal with a thickness of 5 μm and a length of 700μm;

[0042] (3) Select 13.0 grams of Ni powder, 7.0 grams of Al powder, 3.0 grams of Ag powder and 2.0 grams of the Mo...

Embodiment 3

[0047] The preparation technology of the novel NiAl base solid self-lubricating composite material of the present embodiment, it comprises the steps:

[0048] (1) According to the molar ratio of 1:2:1:1, select ammonium molybdate powder, boron powder, zirconium powder and chromium powder for ball mill mixing. The speed of the ball mill is 200 rpm, and the mass ratio of ball to material is 9:1. , the planetary ball milling time is 2.5 hours, and the initial mixture of Mo-B-O-Zr-Cr quinary plate crystals is obtained, and the average particle size of the initial mixture is 10 μm;

[0049] (2) The ingredients after ball milling were sintered by spark plasma sintering equipment. The sintering process was 600°C for 30 minutes, and the protective gas was nitrogen to obtain the Mo-B-O-Zr-Cr five-element plate-shaped crystal with a thickness of 3 μm and a length of 300μm;

[0050] (3) Select 13.0 grams of Ni powder, 7.0 grams of Al powder, 2.4 grams of Ag powder and 1.6 grams of the M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com