Loading nano Ni-B type catalyst by using Al2O3 and C as carrier, and preparation method thereof

A carrier loading and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve complex preparation process, uneven distribution of metal particles, inter-particle It is easy to cause problems such as agglomeration and achieve high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

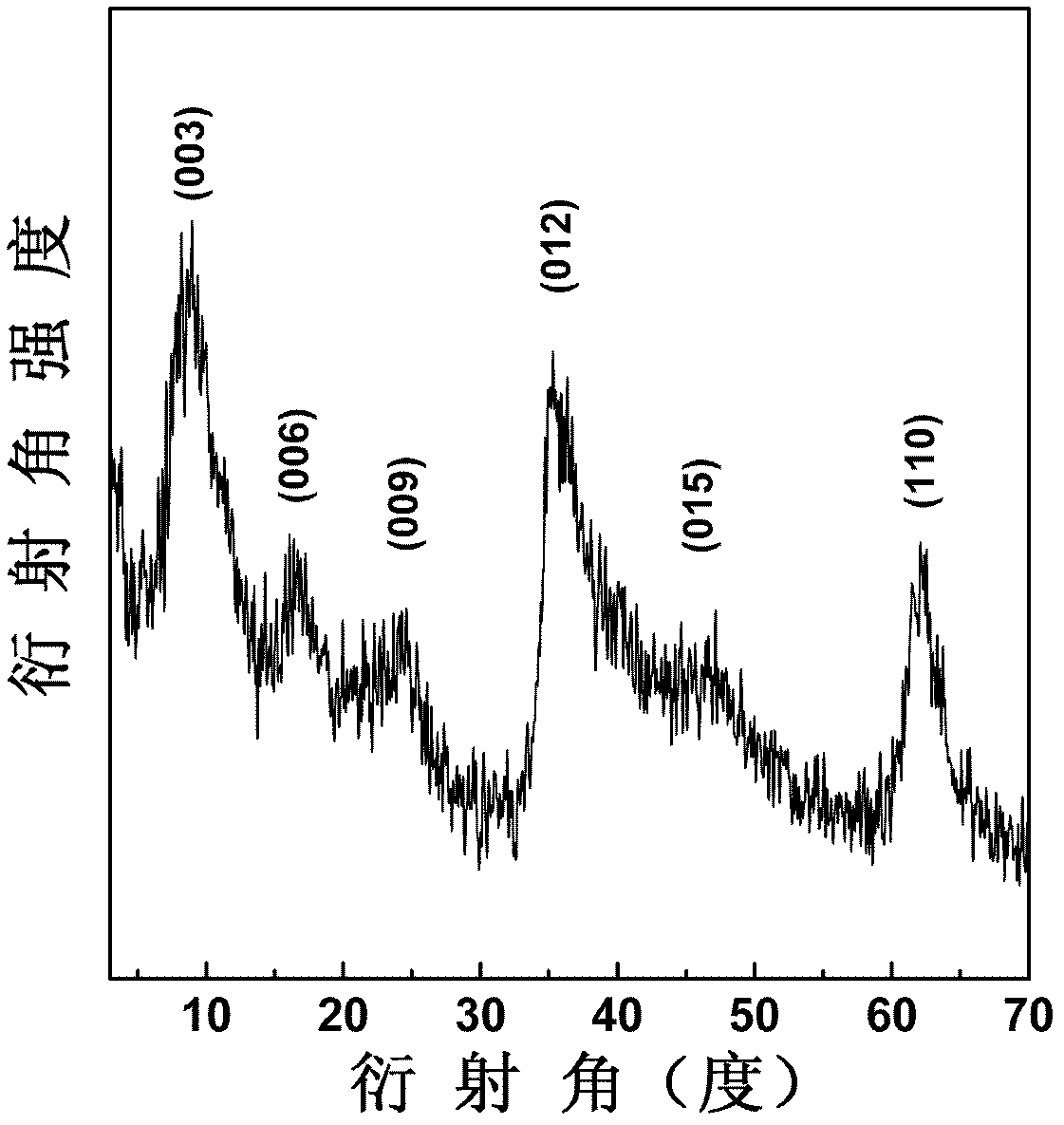

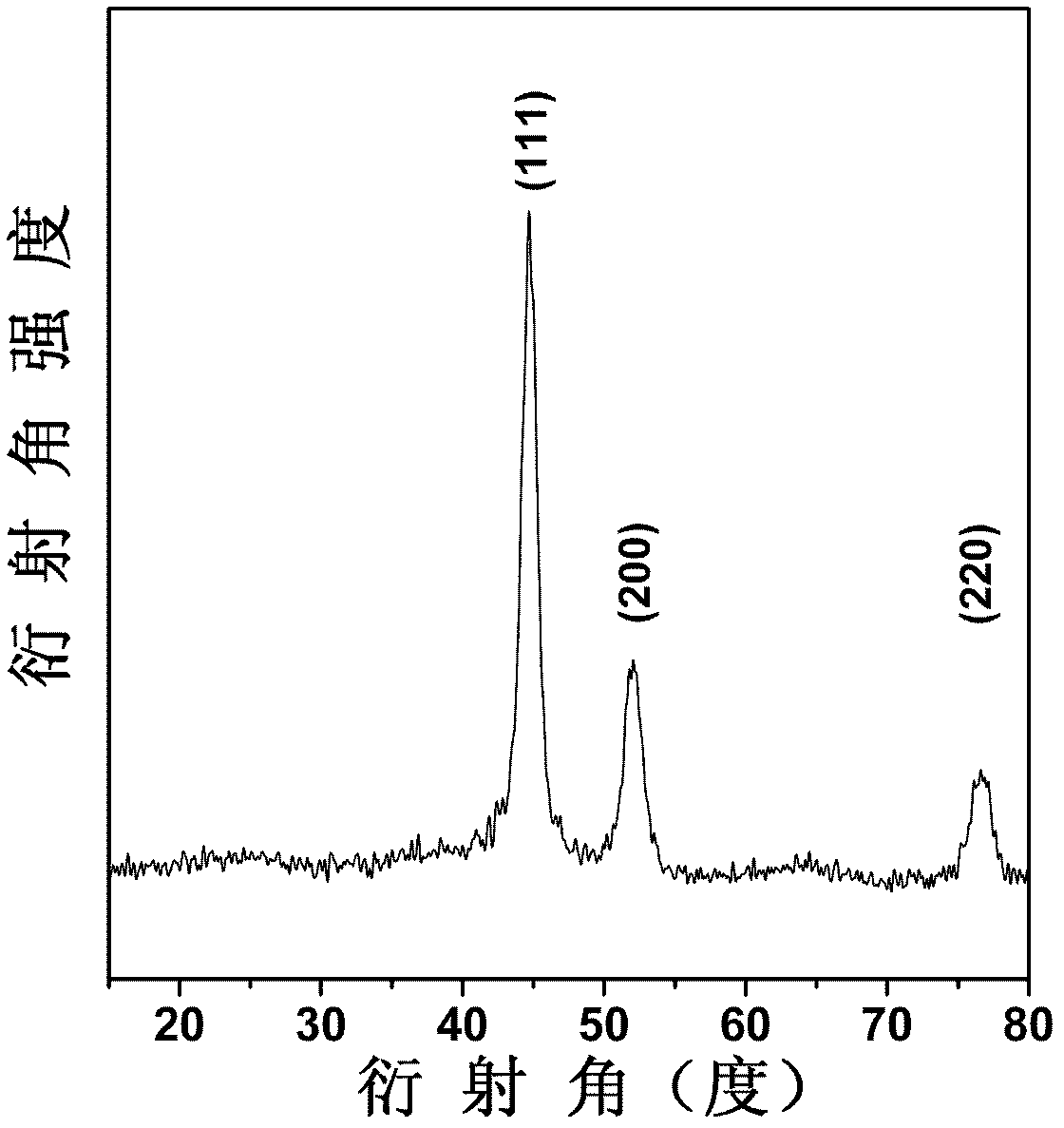

Method used

Image

Examples

Embodiment 1

[0025] 1.454g of Ni(NO 3 ) 2 ·6H 2 O, 1.8757g of Al(NO 3 ) 3 9H 2 O and 1.5457g of H 3 BO 3 Dissolve in 50ml deionized water to prepare Ni(NO 3 ) 2 , Al(NO 3 ) 3 and H 3 BO 3 The mixed solution of which Ni 2+ The concentration is 0.10mol / L, Al 3+ The concentration of boric acid is 0.10mol / L, and the concentration of boric acid is 0.50mol / L; an alkaline solution is prepared by dissolving 3g of NaOH in 100ml of deionized water, wherein the concentration of NaOH is 0.75mol / L.

[0026] Add the mixed solution prepared above into the reaction vessel and ultrasonically disperse for 20 minutes, add the alkaline solution dropwise into the above mixed salt solution reaction vessel, adjust the pH=10 of the solution; 2 Crystallize at 65° C. for 24 hours under atmosphere, cool to room temperature, wash the filter cake with deionized water until neutral, and obtain a precipitate.

[0027] Dissolve 4.95g of glucose into 40ml of deionized water to prepare a solution, mix the pr...

Embodiment 2

[0030] 2.181g of Ni(NO 3 ) 2 ·6H 2 O, 1.8757g of Al(NO 3 ) 3 9H 2 O and 2.3186g of H 3 BO 3 Dissolve in 50ml deionized water to prepare Ni(NO 3 ) 2 , Al(NO 3 ) 3 and H 3 BO 3 The mixed solution of which Ni 2+ The concentration is 0.15mol / L, Al 3+ The concentration of boric acid is 0.10mol / L, and the concentration of boric acid is 0.75mol / L; an alkaline solution is prepared by dissolving 3g of NaOH in 100ml of deionized water, wherein the concentration of NaOH is 0.75mol / L.

[0031] Add the prepared mixed solution into the reaction container, ultrasonically disperse for 20 minutes, take the alkaline solution and add it dropwise to the above-mentioned mixed salt solution reaction container, and adjust the pH of the solution to 10; 2 Crystallize at 65° C. for 24 hours under atmosphere, cool to room temperature, wash the filter cake with deionized water until neutral, and obtain a precipitate.

[0032] Dissolve 6.188g of glucose into 40ml of deionized water to prepa...

Embodiment 3

[0035] 2.908g of Ni(NO 3 ) 2 ·6H 2 O, 1.8757g of Al(NO 3 ) 3 9H 2 O and 3.0915g of H 3 BO 3 Dissolve in 50ml deionized water to prepare Ni(NO 3 ) 2 , Al(NO 3 ) 3 and H 3 BO 3 The mixed solution of which Ni 2+ The concentration is 0.20mol / L, Al 3+ The concentration of boric acid is 0.10mol / L, and the concentration of boric acid is 1.0mol / L; an alkaline solution is prepared by dissolving 3g of NaOH in 100ml of deionized water, wherein the concentration of NaOH is 0.75mol / L.

[0036] Add the prepared mixed solution into the reaction container, ultrasonically disperse for 20 minutes, take the alkaline solution and add it dropwise to the above-mentioned mixed salt solution reaction container, and adjust the pH of the solution to 10; 2 Crystallize at 65° C. for 24 hours under atmosphere, cool to room temperature, wash the filter cake with deionized water until neutral, and obtain a precipitate.

[0037] Dissolve 7.425g of glucose into 40ml of deionized water to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com