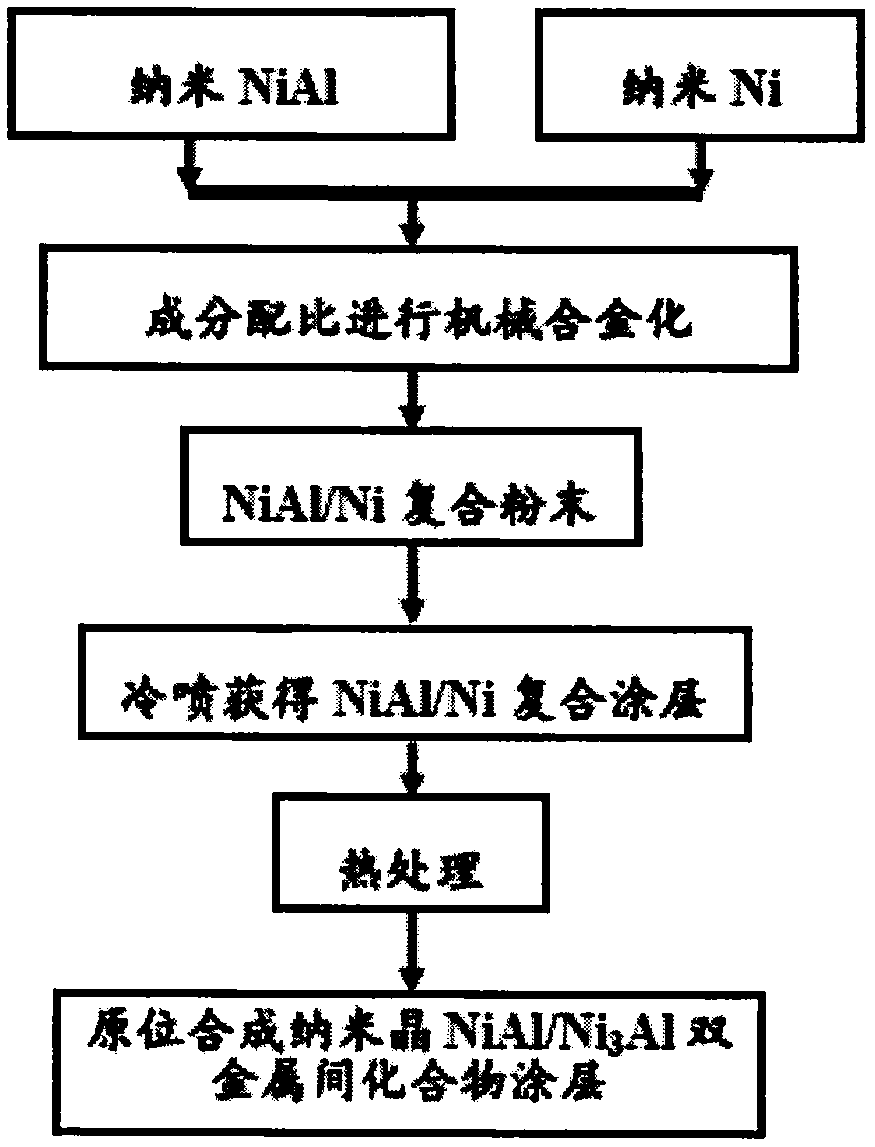

Preparation method for in-situ synthesized nano-crystalline NiAl/Ni3Al intermetallic compound coating

An in-situ synthesis, nanocrystalline technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems of low fracture resistance and high temperature strength, poor temperature plasticity, stress cracking, etc., and achieve the effect of good coating density and good bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Select NiAl powder with a particle size of 50nm and Ni powder with a particle size of 30nm, and obtain agglomerated and coated NiAl / Ni composite powder with a volume fraction of nano-NiAl of 20vol.% through mechanical alloying technology, wherein the ball-to-material ratio is 10: 1. The rotation speed is 250rpm, and the ball milling time is 18h. After the 316L stainless steel and Al plate are subjected to sandblasting and roughening treatment, the agglomerated coated NiAl / Ni composite powder obtained after passing the sieving is used as the spraying material, and the cold spray system is used to deposit NiAl / Ni on the surface of the 316L stainless steel and Al plate. Composite coatings, where the spray gas uses N 2 , the acceleration gas pressure is 2.0MPa, the powder feeding gas pressure is 2.2MPa, the spraying temperature is 300°C, the spraying distance is 10mm, and the coating thickness is 200μm. Put the sprayed coating into an electric furnace protected by an inert...

Embodiment 2

[0025] Select NiAl powder with a particle size of 20nm and Ni powder with a particle size of 10nm, and obtain agglomerated and coated NiAl / Ni composite powder with a volume fraction of nano-NiAl of 40vol.% through mechanical alloying technology, wherein the ball-to-material ratio is 15: 1. The rotation speed is 180rpm, and the ball milling time is 20h. After the 316L stainless steel and Al plate are subjected to sandblasting and roughening treatment, the agglomerated coated NiAl / Ni composite powder obtained after sieving is used as the spraying material, and the NiAl / Ni composite coating is deposited on the surface by a cold spray system. Among them, the spray gas uses N 2 , the acceleration gas pressure is 2.0MPa, the powder feeding gas pressure is 2.2MPa, the spraying temperature is 250°C, the spraying distance is 10mm, and the coating thickness is 250μm. After spraying, the coating is placed in an electric furnace protected by inert gas for heat treatment, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com