Liquid insulating glue for cable joint

A technology of liquid insulation and cable joints, applied in the field of chemicals, can solve problems such as poor contact, fire, and increased contact resistance, and achieve the effects of excellent insulation performance, fast solvent volatilization, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

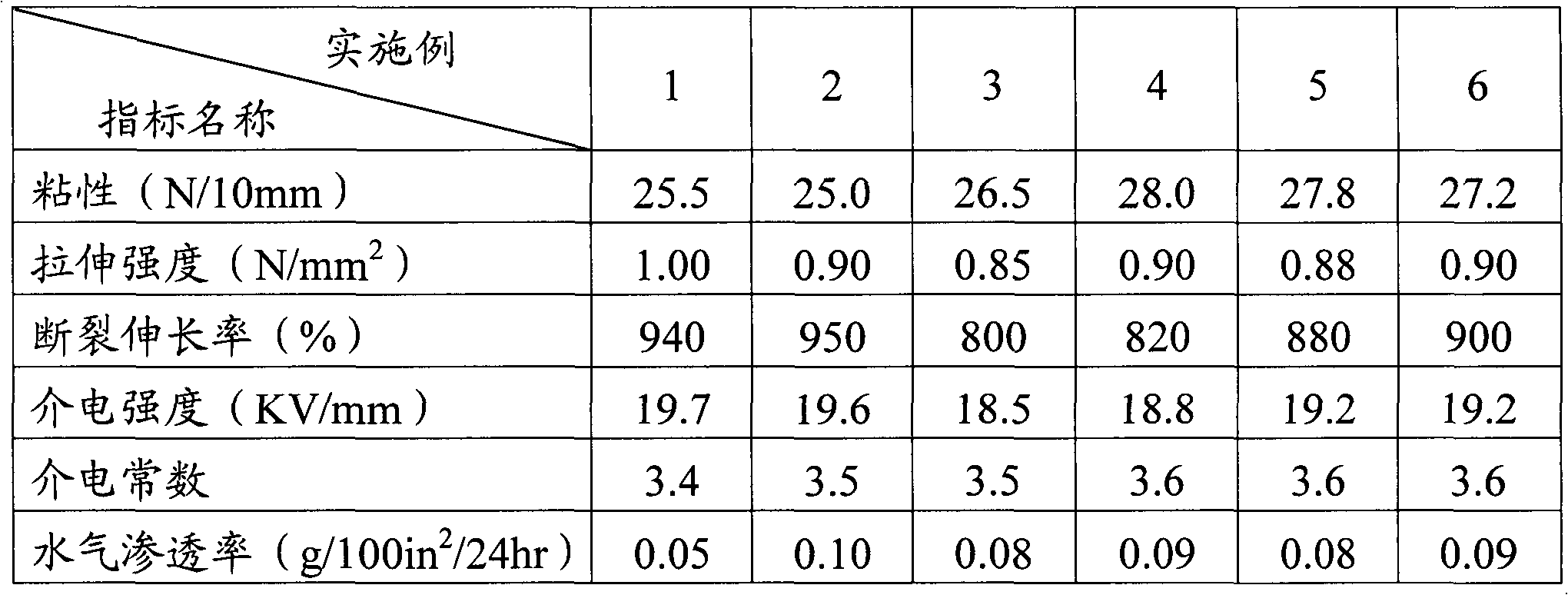

Examples

Embodiment 1

[0016] Take 25 kg of modified chloroprene rubber, add 50 kg of xylene and soak for 2 hours, after the modified chloroprene rubber is expanded, add xylene to dilute to 100 kg, stir evenly, and take a sample for testing.

Embodiment 2

[0018] Get 13 kilograms of modified chloroprene rubber, 12 kilograms of modified styrene-butadiene rubber, add 50 kilograms of xylene and soak for 2 hours, after the modified chloroprene rubber and modified styrene-butadiene rubber are expanded, add toluene to dilute to 100 kilograms, stir Uniform, sample test.

Embodiment 3

[0020] Take 30 kg of modified butyl rubber, 0.5 kg of rosin, add 50 kg of xylene and soak for 2 hours, after the modified butyl rubber is expanded, add benzene to dilute to 100 kg, stir evenly, and take samples for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com